Low-alloying copper belt and preparation method thereof

A low-alloy, copper strip technology, applied in the field of low-alloy copper strips, can solve the problems of inability to meet the high conductivity requirements of connectors, unsuitable connectors, and low conductivity, so as to improve market competitiveness and strength And the effect of stress relaxation resistance and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

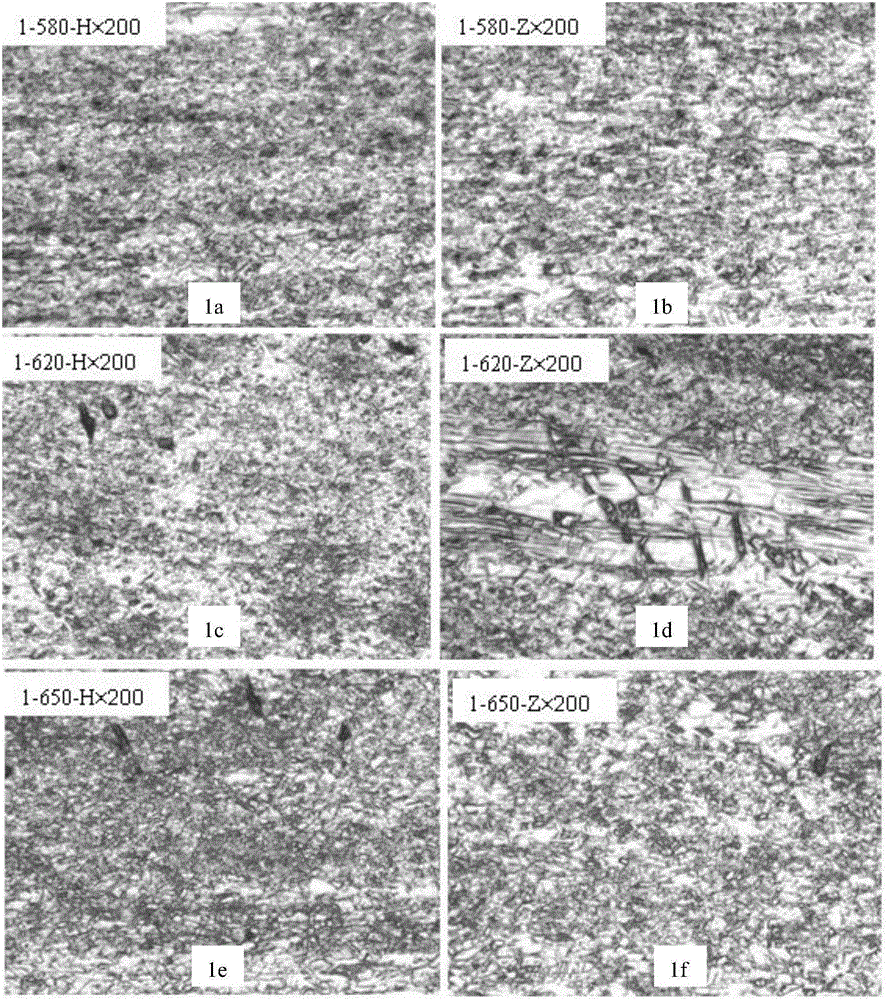

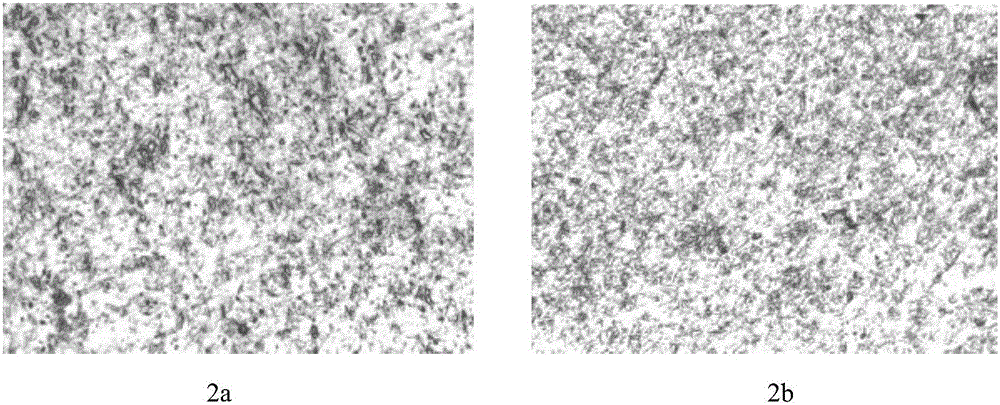

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0026] The preparation method of low-alloyed copper strip in the present invention comprises the following steps:

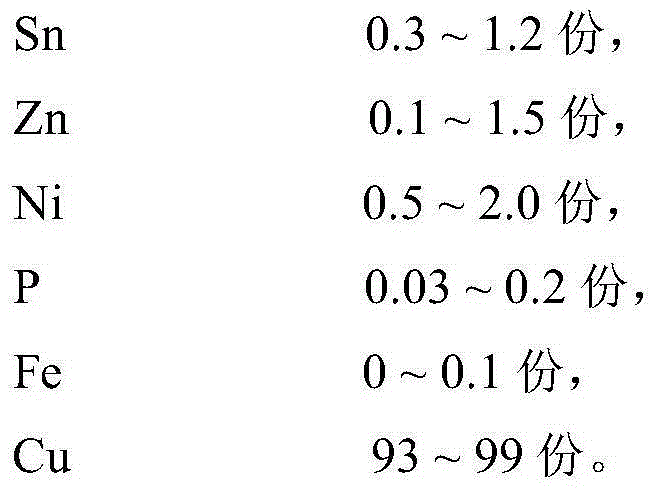

[0027] (1) In terms of weight percentage, according to the formula of the low-alloyed copper strip in Table 5, the corresponding amount of raw materials is weighed, and electrolytic copper, electrolytic nickel, phosphor copper alloy, zinc ingot, and tin ingot are sequentially added in the induction furnace for smelting, It is covered with charcoal, and the melting temperature is 1200-1250 ° C. After all the metals are melted, the ingredients are refined and adjusted;

[0028] (2) Carry out horizontal continuous casting to the copper alloy cast slab obtained in step (1), the casting temperature is 1150~1250 ℃;

[0029] (3) Wash the surface of the copper alloy cast slab obtained in step (2) and carry out cold rolling treatment. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com