Alnbc/alnbcn laminated composite coating tool and its preparation process

A composite coating and coating technology, applied in the direction of metal material coating process, coating, vacuum evaporation plating, etc., can solve the problems of restricting wide application, coating equipment pollution, adverse influence of substrate, etc., and achieve improved bonding performance , low surface friction, and the effect of improving high temperature oxidation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

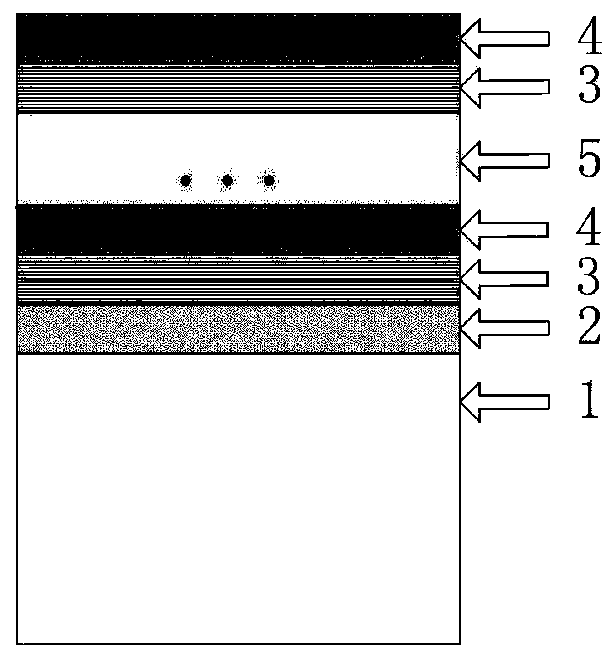

[0032]The AlNbC / AlNbCN laminated composite coating tool described in this embodiment is an ordinary turning blade, and its base material is: cemented carbide M10, and a coating is deposited on the surface of the tool base, and the coating is from the inside to the outside. The order is: Ti transition layer, AlNbC coating and AlNbCN coating alternate laminated composite structure, the outermost layer is AlNbCN coating.

[0033] The preparation process of the AlNbC / AlNbCN laminated composite coating tool described in this example, the deposition method is the unbalanced magnetron sputtering + arc ion plating composite coating method, and two unbalanced magnetron sputtering AlNbC composite coatings are used for deposition. Targets, 2 arc ion plating Ti targets: Firstly, the Ti transition layer is deposited by arc ion plating, and then the unbalanced magnetron sputtering method is used to alternately deposit AlNbC coating and AlNbCN coating, and the outermost layer is AlNbCN coatin...

Embodiment 2

[0045] The AlNbC / AlNbCN laminated composite coating tool described in this embodiment is an ordinary welding turning tool, and its base material is: high-speed steel W18Cr4V, and a coating is deposited on the surface of the tool base, and the coating is from the inside to the outside. The order is: Ti transition layer, AlNbC coating and AlNbCN coating alternate laminated composite structure, the outermost layer is AlNbCN coating.

[0046] The preparation process of the AlNbC / AlNbCN laminated composite coating tool described in this example, the deposition method is the unbalanced magnetron sputtering + arc ion plating composite coating method, and two unbalanced magnetron sputtering AlNbC composite coatings are used for deposition. Targets, 2 arc ion plating Ti targets: Firstly, the Ti transition layer is deposited by arc ion plating, and then the unbalanced magnetron sputtering method is used to alternately deposit AlNbC coating and AlNbCN coating, and the outermost layer is A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com