Method for preparing sulfate/silicate-resistant cement clinker by taking low-aluminum stone coal vanadium-extracting slag and nitric phosphate slag as main raw materials

A technology of portland cement and nitrophosphate fertilizer, which is applied in cement production, etc., can solve problems such as large environmental loads and safety hazards, and achieve the effects of reducing grinding costs, high mixing degree, and good grindability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

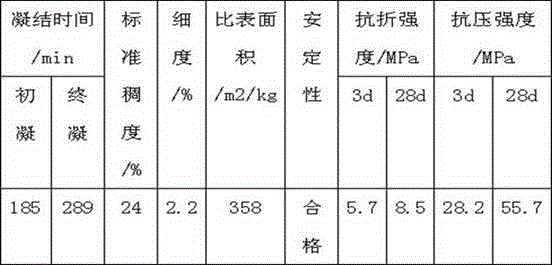

[0017] The vanadium extraction slag obtained by using stone coal through fluidized bed furnace decarbonization roasting, rotary kiln oxidation roasting, acid leaching and other processes is used as siliceous raw material, nitrophosphate fertilizer slag is used as calcium raw material, Al 2 o 3 Bauxite ore with a content of about 65% is aluminum raw material, Fe 2 o 3 Iron ore with a content of about 75% is used as iron raw material for high sulfate-resistant Portland cement clinker firing. The main composition of each raw material is shown in Table 1. Take crushed low-alumina stone coal vanadium extraction slag 14.2%, nitrophosphate fertilizer slag 77.3%, bauxite 3.9%, iron ore 4.6%, mix each raw material in proportion, and then grind and homogenize in a ball mill , Grind to a particle size of less than 0.074mm. The obtained raw meal powder is put into a kiln for calcination at 1350-1450°C, and forced air cooling after sintering to obtain sulfate-resistant Portland cement ...

Embodiment 2

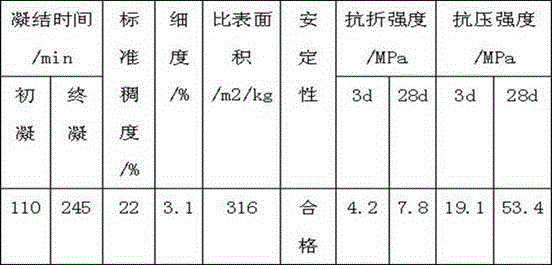

[0025] The vanadium extraction slag obtained by using stone coal through fluidized bed furnace decarbonization roasting, rotary kiln oxidation roasting, acid leaching and other processes is used as siliceous raw material, nitrophosphate fertilizer slag is used as calcium raw material, Al 2 o 3 Coal gangue with a content of about 17% is aluminum raw material, Fe 2 o 3 Copper slag with a content of about 47% is ferrous raw material for medium sulfate-resistant Portland cement clinker firing. The main composition of each raw material is shown in Table 4. Take crushed low-alumina stone coal vanadium extraction slag 3.8%, nitrophosphate fertilizer slag 76.8%, coal gangue 14.4%, copper slag 5.0%, mix each raw material in proportion, grind and homogenize in a ball mill, grind To a particle size of less than 0.074mm. The obtained raw meal powder is put into a kiln for calcination at 1350-1450°C, and forced air cooling after sintering to obtain sulfate-resistant Portland cement cli...

Embodiment 3

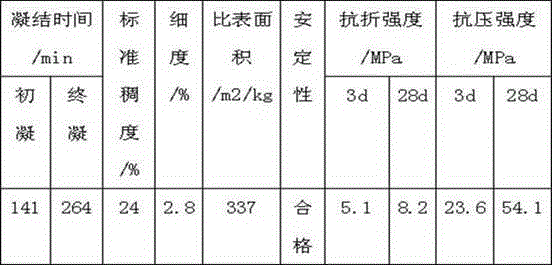

[0033] The vanadium extraction slag obtained by using stone coal through fluidized bed furnace decarbonization roasting, rotary kiln oxidation roasting, acid leaching and other processes is used as siliceous raw material, nitrophosphate fertilizer slag is used as calcium raw material, Al 2 o 3 Coal ash with a content of about 32% is aluminum raw material, Fe 2 o 3 The sulfuric acid slag with a content of about 53% is ferrous raw material for high sulfate-resistant Portland cement clinker firing. The main composition of each raw material is shown in Table 7. Take 10.5% of vanadium extraction slag from crushed low-alumina stone coal, 77.8% of nitrophosphate fertilizer slag, 6.5% of coal ash, and 5.2% of sulfuric acid slag. To a particle size of less than 0.074mm. The obtained raw meal powder is put into a kiln for calcination at 1350-1450°C, and forced air cooling after sintering to obtain sulfate-resistant Portland cement clinker. The chemical composition and mineral compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com