Zinc-based alloy used in steel hot dipping, and preparation method thereof

A hot-dip galvanizing and base alloy technology, applied in hot-dip galvanizing process, metal material coating process, coating, etc., can solve the problem of excessive slag, improve product quality, reduce production cost, and reduce viscosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

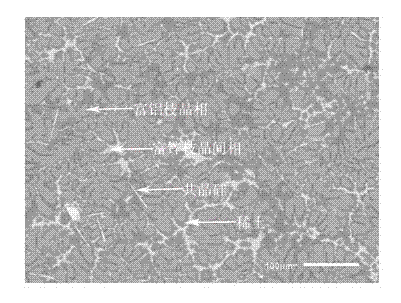

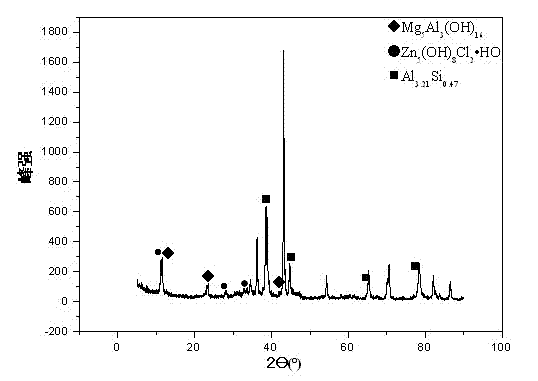

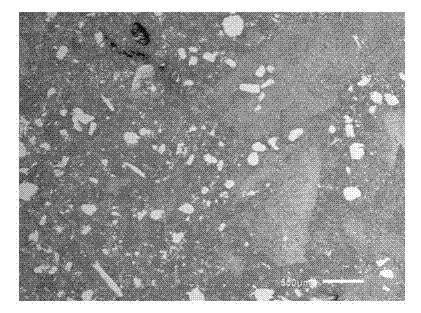

Image

Examples

preparation example Construction

[0026] 1. Preparation of Al-Si Master Alloy

[0027] Put the aluminum ingot accounting for 80% of the weight of the Al-Si master alloy into the medium-frequency induction furnace, raise the temperature to 720°C, add a salt covering agent on the surface of the aluminum liquid, and use a bell jar to press the silicon block accounting for 20% of the weight of the Al-Si master alloy. Pour into molten aluminum, smelt, stir until uniform, keep warm for 30 minutes, and cast into a copper mold with an inner diameter of 50mm.

[0028] 2. Preparation of Al-Mg Master Alloy

[0029]First, preheat the magnesium ingot accounting for 10% of the weight of the Al-Mg master alloy and the aluminum ingot accounting for 90% of the weight of the Al-Mg master alloy to 200°C, preheat the crucible to a dark red color of about 500°C, and sprinkle the crucible wall and bottom with Appropriate amount of RJ-5 solvent; then add the preheated aluminum ingot to the crucible, raise the temperature to 700°C, ...

Embodiment 1

[0048] Step 1: Add zinc ingots accounting for 60% of the weight of the Zn-Al alloy into an intermediate frequency induction furnace, raise the temperature to 650°C, add aluminum ingots accounting for 40% of the weight of the Zn-Al alloy, melt and stir for 20 minutes; cool down to 600°C And keep it warm for 30 minutes, and cast the ingot into Zn-Al master alloy;

[0049] The second step: select Al-Si master alloy, Al-Mg master alloy and Al-La master alloy as the object of alloying treatment, or prepare the above-mentioned master alloy by the following method.

[0050] 1. Preparation of Al-Si Master Alloy

[0051] Put the aluminum ingot accounting for 80% of the weight of the Al-Si master alloy into the medium-frequency induction furnace, raise the temperature to 720°C, add a salt covering agent on the surface of the aluminum liquid, and use a bell jar to press the silicon block accounting for 20% of the weight of the Al-Si master alloy. Pour into molten aluminum, smelt, stir u...

Embodiment 2

[0060] The first and second steps of the alloy preparation method are the same as in Example 1.

[0061] Step 3: Put the zinc ingot accounting for 44.4% of the total weight of the alloy and the zinc-aluminum master alloy accounting for 28.5% of the total weight of the alloy in a medium-frequency induction furnace, raise the temperature to 720°C, add a salt covering agent on the surface of the alloy liquid, and use a clock Press the aluminum-silicon intermediate alloy with 7.5% of the total weight of the alloy into the alloy liquid, smelt and stir to mix evenly; cool down to 650°C, use a bell jar to mix the aluminum-magnesium intermediate alloy with 16% of the total weight of the alloy and 3.6% of the total weight The aluminum-lanthanum master alloys were respectively pressed into the molten alloy solution, stirred continuously until uniform, kept for 30 minutes, slag was removed, and poured into a metal mold of 300×150mm.

[0062] The alloy prepared through the above three ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com