Brush auxiliary force rheological polishing device for thin-wall annular part and polishing method

A polishing device and auxiliary force technology, used in grinding/polishing equipment, machine tools for surface polishing, grinding workpiece supports, etc., can solve the problem of affecting the polishing effect of thin-walled annular parts, hindering the flow of polishing liquid through the gap, and relying on manual experience. Large and other problems, to achieve the effect of good polishing effect, simplified structure and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation methods (including examples), but it is not used as a basis for limiting the present invention.

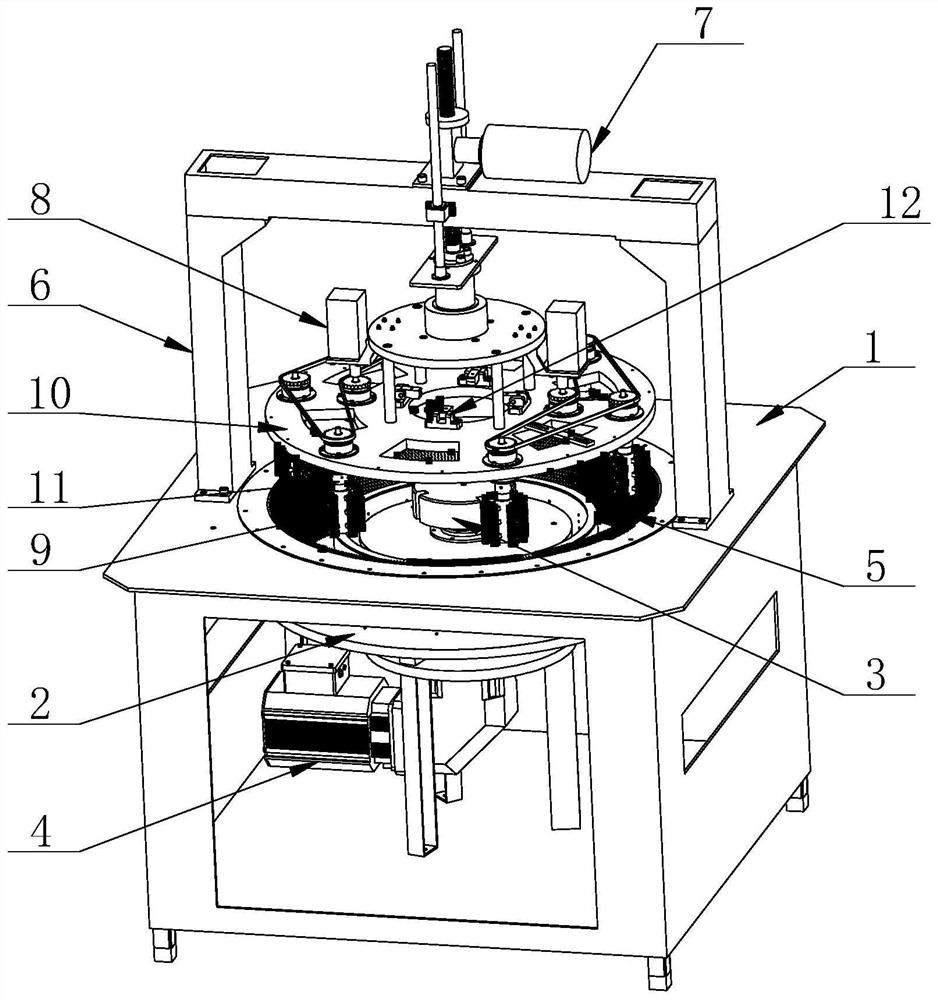

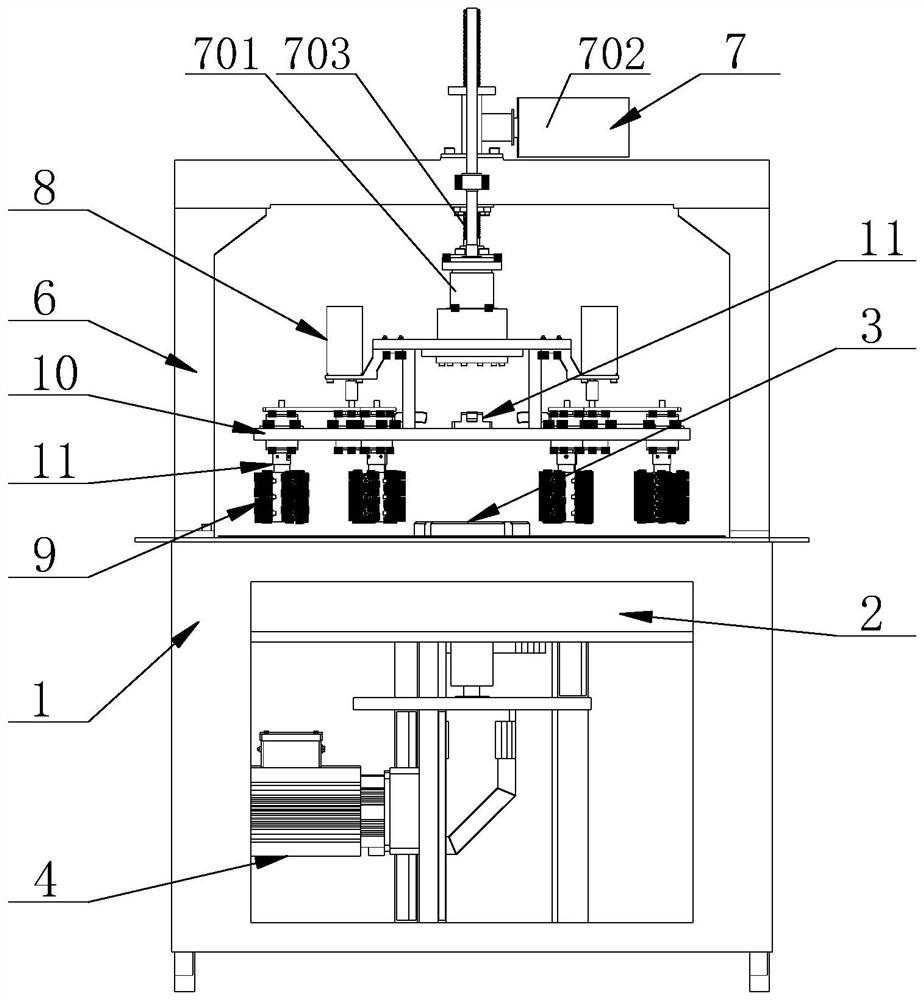

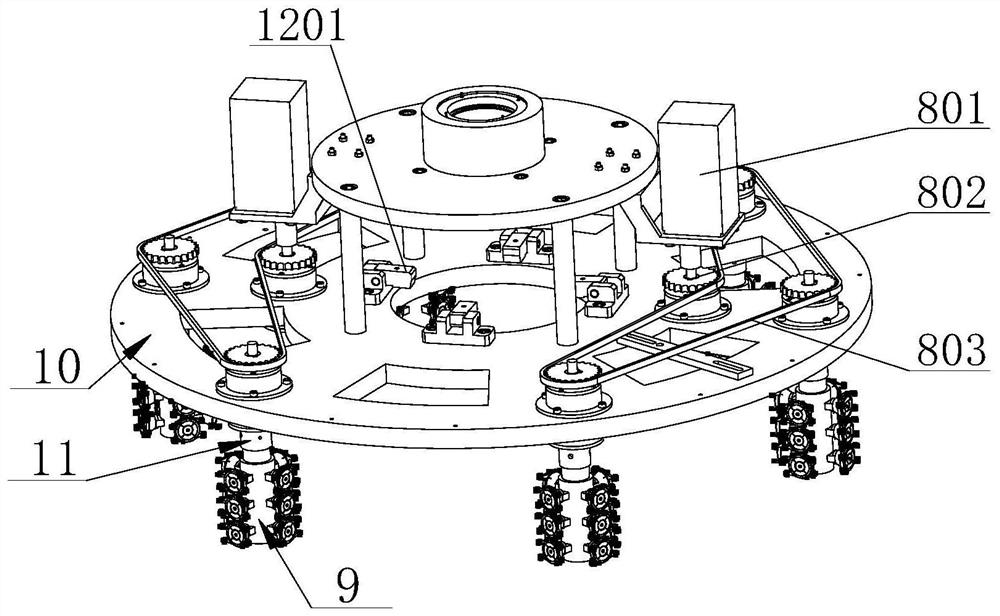

[0027] see Figure 1-8, the present invention provides a brush-assisted force rheological polishing device for thin-walled annular parts, which includes a mounting table 1, a polishing circular groove 2 is installed on the mounting table 1, and a turntable 3 is provided at the center of the bottom of the polishing circular groove 2 , the turntable 3 is connected with the rotating motor 4; the powerful rheological polishing liquid is contained in the polishing circular groove 2, and the inner cavity of the polishing circular groove 2 is provided with a brush 5; Mounting frame 6 is provided, and described mounting frame 6 is positioned at the top of polishing circular groove 2, and lifting device 7 is installed on described mounting frame 6, and turn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com