Rice polishing device

A polishing device and rice technology, applied in grain finishing, grain processing, application, etc., can solve the problems of uneven polishing, poor polishing effect, high broken rice rate, etc., to ensure uniformity, improve smoothness, and ensure polishing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

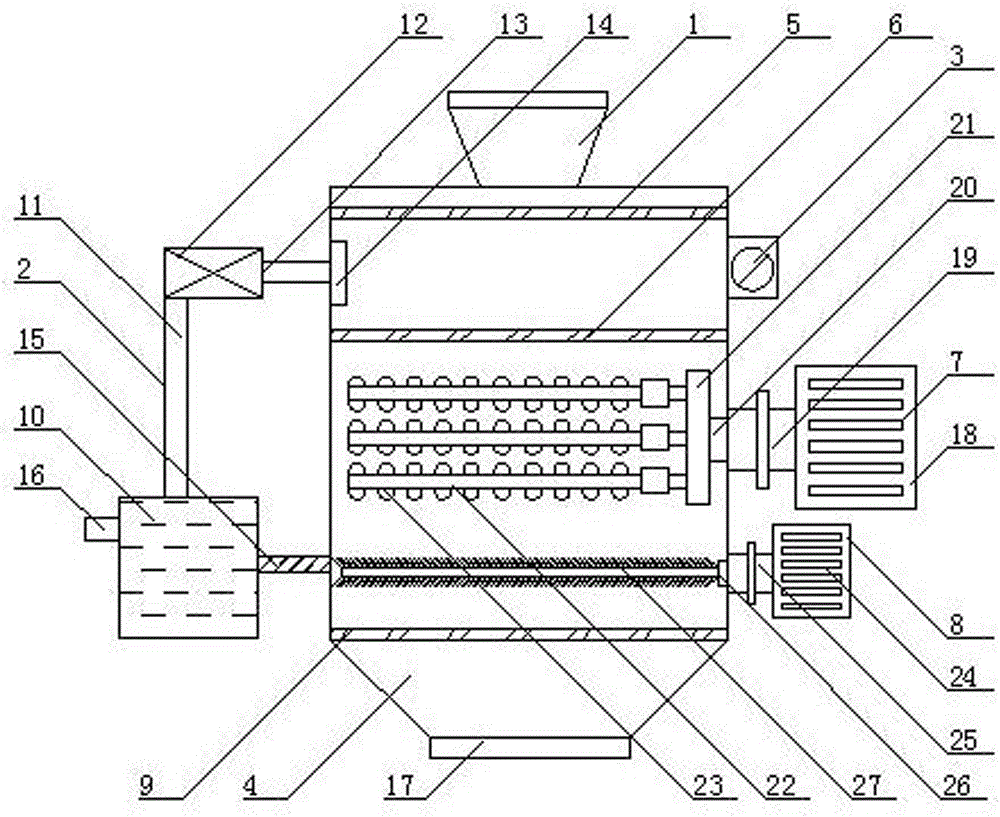

[0016] As shown in the figure, a rice polishing device includes a fuselage, a feed funnel 1 is installed in the middle of the top of the fuselage, a watering device 2 is installed on the left side of the fuselage, a circulating fan 3 is installed on the upper end of the right side of the fuselage, and the bottom of the fuselage The end is equipped with a conical discharge bin 4, the upper end of the fuselage is equipped with a first filter screen 5, the middle and upper end of the fuselage is equipped with a second filter 6, the middle end of the fuselage is equipped with a polisher 7, and the middle and lower end of the fuselage is equipped with rice brushing device 8, the third filter screen 9 of the lower end device inside the fuselage.

[0017] The sprinkler 2 is composed of a water tank 10, an outlet pipe 11, an atomizer 12, an atomizing pipe 13, and a spray outlet 14. The upper end of the left side of 10 is equipped with a water inlet pipe 16, the middle of the top of th...

Embodiment 2

[0022] Further, the apertures of the first filter 5, the second filter 6 and the third filter 9 are the same, and the apertures of all three are 1-2 mm larger than the diameter of rice grains.

Embodiment 3

[0024] Further, the bristles are nylon bristles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com