Polishing device having environmental protection function and used for gear blank machining

A technology of polishing device and tooth blank, which is applied in grinding/polishing safety device, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of high energy consumption, small gear size, cumbersome polishing work, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

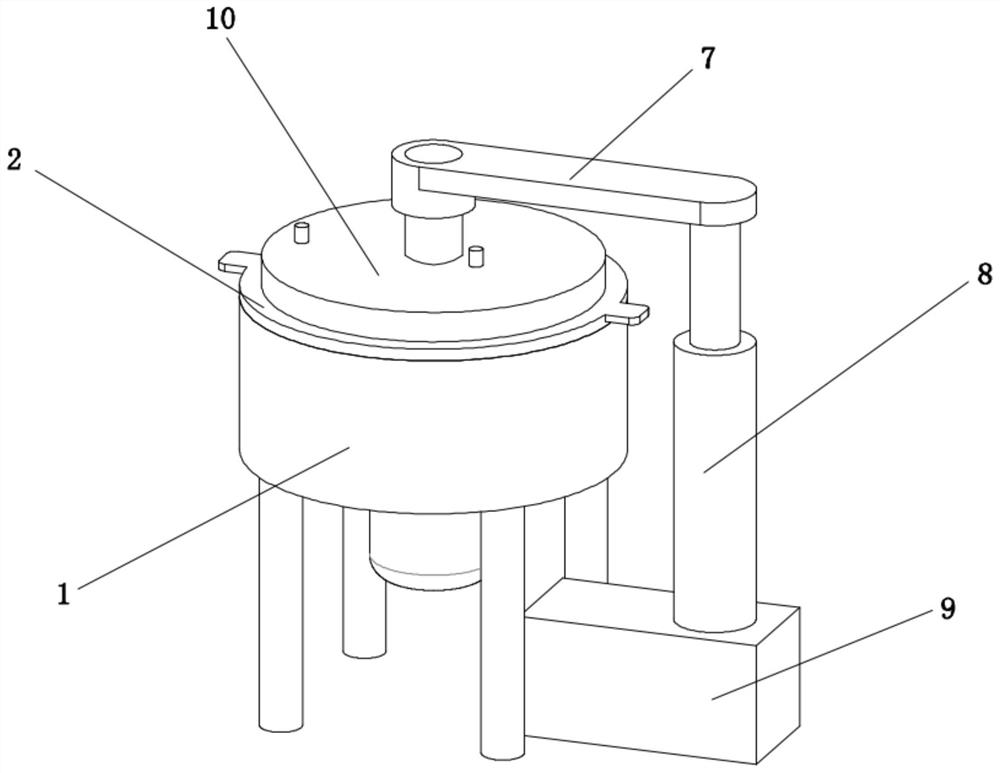

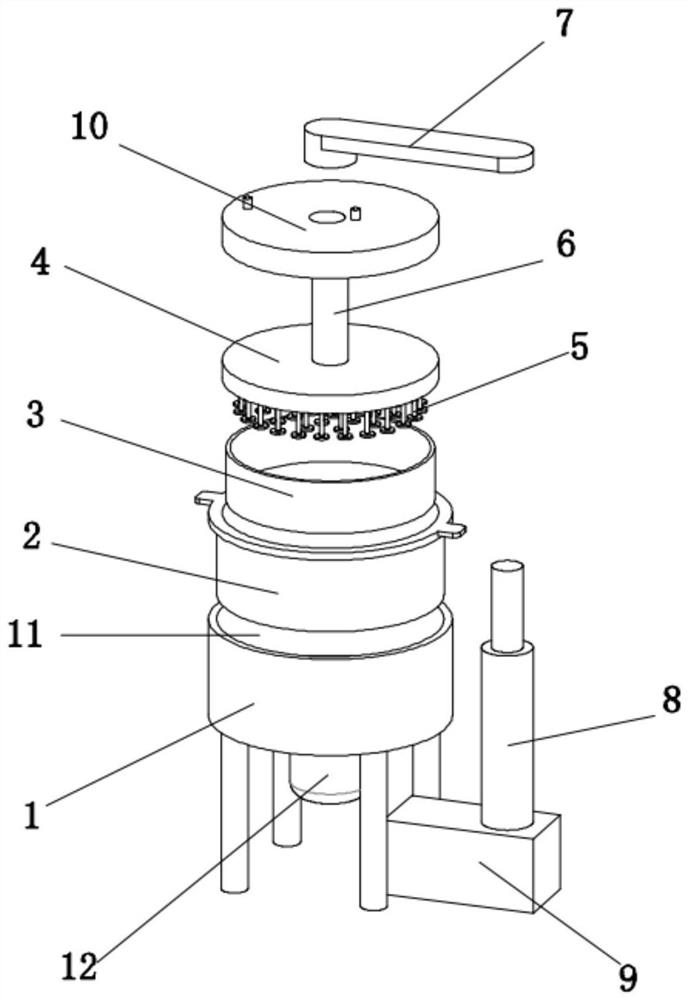

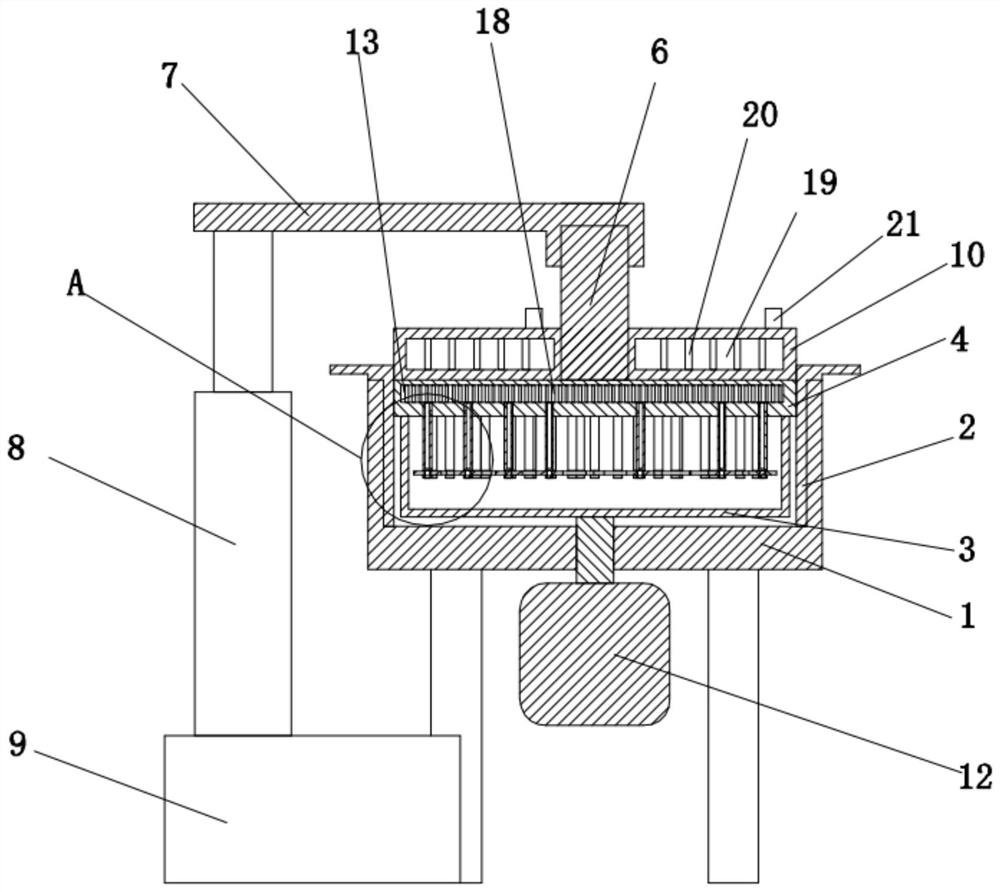

[0034] See Figure 1-7 A polishing apparatus having a environmentally friendly function of a tooth blank, including a polishing tub 1, a polishing chamber 11, and a polishing cavity 11 is provided in the polishing chamber 11, and the bottom center of the polishing tub 1 is provided. The polishing motor 12 polishing the output shaft of the motor 12 penetrates the bottom of the polishing tub 1, and the upper end of the output shaft of the polishing motor 12 is fixed to the bottom center of the polishing tub 3, and the polishing cavity 11 is contained in the polishing chamber 11, and the shot drum 3 The polishing medium is loaded, and the upper end of the polishing chamber 11 is inserted with a tooth blade fixing frame 4, and the lower end of the tooth blade fixing frame 4 is uniformly distributed with a plurality of cooling fixing rods 5, and the plurality of cooling fixing rods 5 are inserted into the polishing bucket. Inside, the cosbend fixing frame 4 is opened in the tooth blade ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com