Silica sol with convex colloid surface, preparation method and application of silica sol

A technology of silica sol and colloid, which is applied in the direction of chemical instruments and methods, silicon compounds, polishing compositions containing abrasives, etc., can solve the problem that it is difficult to obtain silica sol and silica gel with protrusions on the surface of silica colloid particles. The problem of low surface roughness of bulk particles can be solved to achieve the effects of reducing defects and scratches, high hardness and improving grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

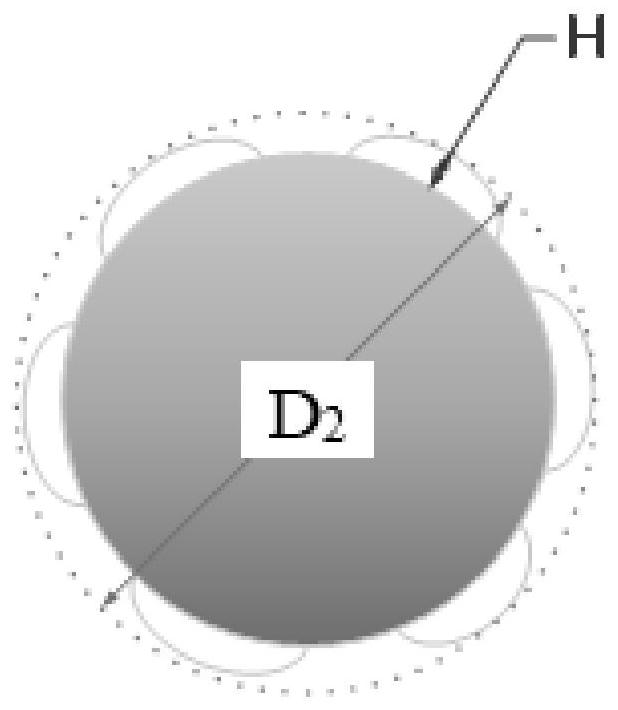

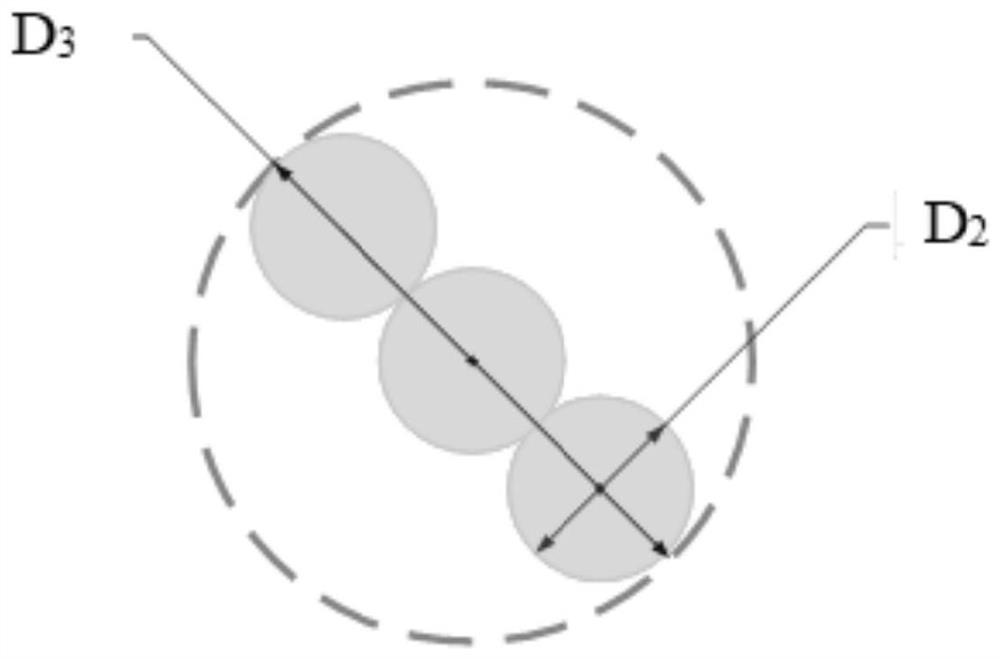

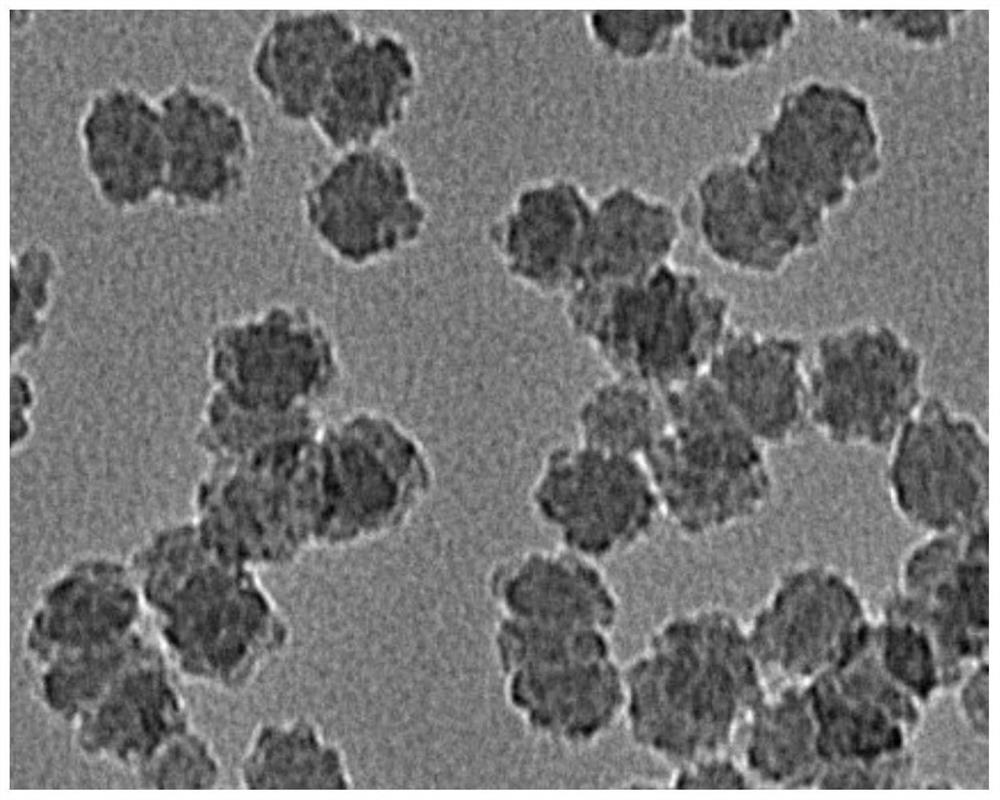

[0053] A kind of silica sol whose colloidal surface is convex, including liquid medium water and colloidal particles, said colloidal particles are mace-shaped silica colloidal particles with raised surfaces, and the height H of said protrusions is 5.1 nm; the fitted particle diameter of the nitrogen adsorption BET specific surface area of the silica colloidal particles is D 1 , the short-axis particle diameter obtained by TEM characterization is D 2 , the particle size measured by dynamic light scattering is D 3 ,D 2 / D 1 is 1.73, and D 3 / D 1 is 3.38.

[0054] The above-mentioned colloidal surface is the preparation method of convex silica sol, specifically comprises the following steps:

[0055] Add 3.4kg of tetramethoxysilane dropwise to a mixed solution containing 10.1kg of ultrapure water and 1.9g of 3-ethoxypropylamine at 80°C and react for 1 hour to obtain a silica sol seed liquid with a pH of 6.26. Among them, the primary particle size of the seed particles is...

Embodiment 2

[0058] A kind of silica sol with convex colloidal surface, including liquid medium water and colloidal particles, the colloidal particles are mace-shaped silica colloidal particles with convex surfaces, and the height H of the convexities is 5.2 nm; the fitted particle diameter of the nitrogen adsorption BET specific surface area of the silica colloidal particles is D 1 , the short-axis particle diameter obtained by TEM characterization is D 2 , the particle size measured by dynamic light scattering is D 3 , 1.2≤D 2 / D 1 is 1.71, and D 3 / D 1 is 3.59.

[0059] The above-mentioned colloidal surface is the preparation method of convex silica sol, specifically comprises the following steps:

[0060] Add 3.4kg of tetramethoxysilane dropwise to a mixed solution containing 10.1kg of ultrapure water and 1.9g of 3-ethoxypropylamine at 80°C and react for 1 hour to obtain a silica sol seed liquid with a pH of 6.26. Among them, the primary particle size of the seed crystal parti...

Embodiment 3

[0063] A kind of silica sol with convex colloidal surface, including liquid medium water and colloidal particles, the colloidal particles are mace-shaped silica colloidal particles with convex surfaces, and the height H of the convexities is 5.4 nm; the fitted particle diameter of the nitrogen adsorption BET specific surface area of the silica colloidal particles is D 1 , the short-axis particle diameter obtained by TEM characterization is D 2 , the particle size measured by dynamic light scattering is D 3 ,D 2 / D 1 is 1.72, and D 3 / D 1 is 4.01.

[0064] The above-mentioned colloidal surface is the preparation method of convex silica sol, specifically comprises the following steps:

[0065] Add 3.4kg of tetramethoxysilane dropwise to a mixed solution containing 10.1kg of ultrapure water and 1.9g of 3-ethoxypropylamine at 80°C and react for 1 hour to obtain a silica sol seed liquid with a pH of 6.26. Among them, the primary particle size of the seed crystal particles ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com