Frozen consolidated abrasive polishing pad bearing device and polishing pad thereof

A technology of consolidating abrasives and bearing devices, which is applied in the direction of abrasives, metal processing equipment, manufacturing tools, etc., can solve problems such as poor rigidity, poor polishing efficiency, and short melting speed and lifespan, so as to prevent rotation, slow down melting rate, and transfer hot slow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

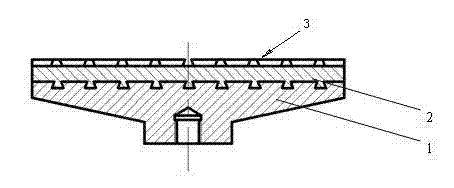

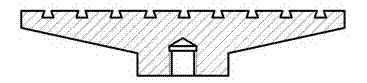

[0029] Such as figure 1 , 2 , 3, 4 shown.

[0030] A frozen solidified abrasive polishing pad bearing device aims at making the frozen solidified abrasive polishing disc bearing device have a certain rigidity and uniformly controlling the melting rate of the frozen solidified abrasive polishing disc. The carrying device is mainly composed of a stiffness providing layer 1 and a heat insulating layer 2. The greater the difference in thermal conductivity between the stiffness providing layer 1 and the heat insulating layer 2, the better, and the diameters of the stiffness providing layer 1 and the heat insulating layer 2 are the same, such as figure 1 As shown, the thermal insulation layer 2 is above the stiffness-providing layer 1, and the rigidity-providing layer 1 and the thermal insulation layer 2 can be connected through a screw structure, or can be connected in a form similar to a dovetail groove structure, such as figure 2 shown. The overall shape of the stiffness-prov...

Embodiment 2

[0033] Such as figure 1 shown.

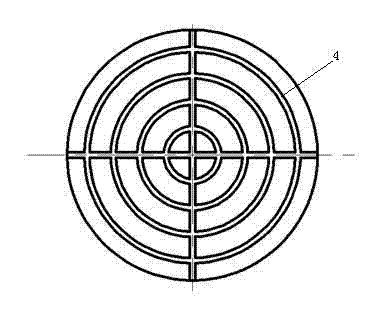

[0034] A kind of frozen solidified abrasive polishing pad with heat insulation layer, it is mainly made up of carrying device and polishing disk 3 of embodiment one, as figure 1 According to the method, the carrying device is mainly composed of a rigidity providing layer 1 made of cast iron and a heat insulating layer 2 made of polytetrafluoroethylene. The heat insulating layer 2 is located between the rigidity providing layer 1 and the polishing disc 3, and the heat insulating layer 2 One side of the heat insulating layer 2 is connected with the rigidity providing layer 1, and the other side of the heat insulating layer 2 is frozen and connected with the frozen solidified abrasive layer forming the polishing disc 3. layer infiltrated so as to connect the thermal insulation layer 2 and the polishing disc 3 by freezing a plurality of annular dovetail grooves 4 with an equal difference in diameter ( image 3 ) or evenly and symmetrically arrang...

example 1

[0037] The melting thickness curve of the ice plate adopting the traditional cast iron plate and the polishing pad carrying device of the present invention is as follows Figure 4 shown. It can be seen that due to the heat exchange between the traditional cast iron plate and the surrounding environment, the melting rate of the ice plate is very fast, and the melting thickness reaches 11.5mm in 60 minutes, while the freezing thickness of the general frozen solid abrasive polishing plate is about 15mm. Therefore, basically the service life of the frozen solidified abrasive polishing disc is about 60 minutes. However, after adopting the polishing pad carrying device of the present invention, due to the existence of the heat insulating layer, the melting thickness of the polishing pad is only 6 mm after 60 minutes. The service life of the frozen solidified abrasive polishing disc is increased by more than 100%.

[0038] At the same time, by adopting the invented polishing pad ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com