Polishing device and technology for false tooth machining

A polishing device and denture technology, applied in the field of denture processing, can solve the problems of inconvenience in the grinding process, inconvenient adjustment of the mounting seat, etc., and achieve the effects of convenient grinding process, uniform clamping force, and reduced displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

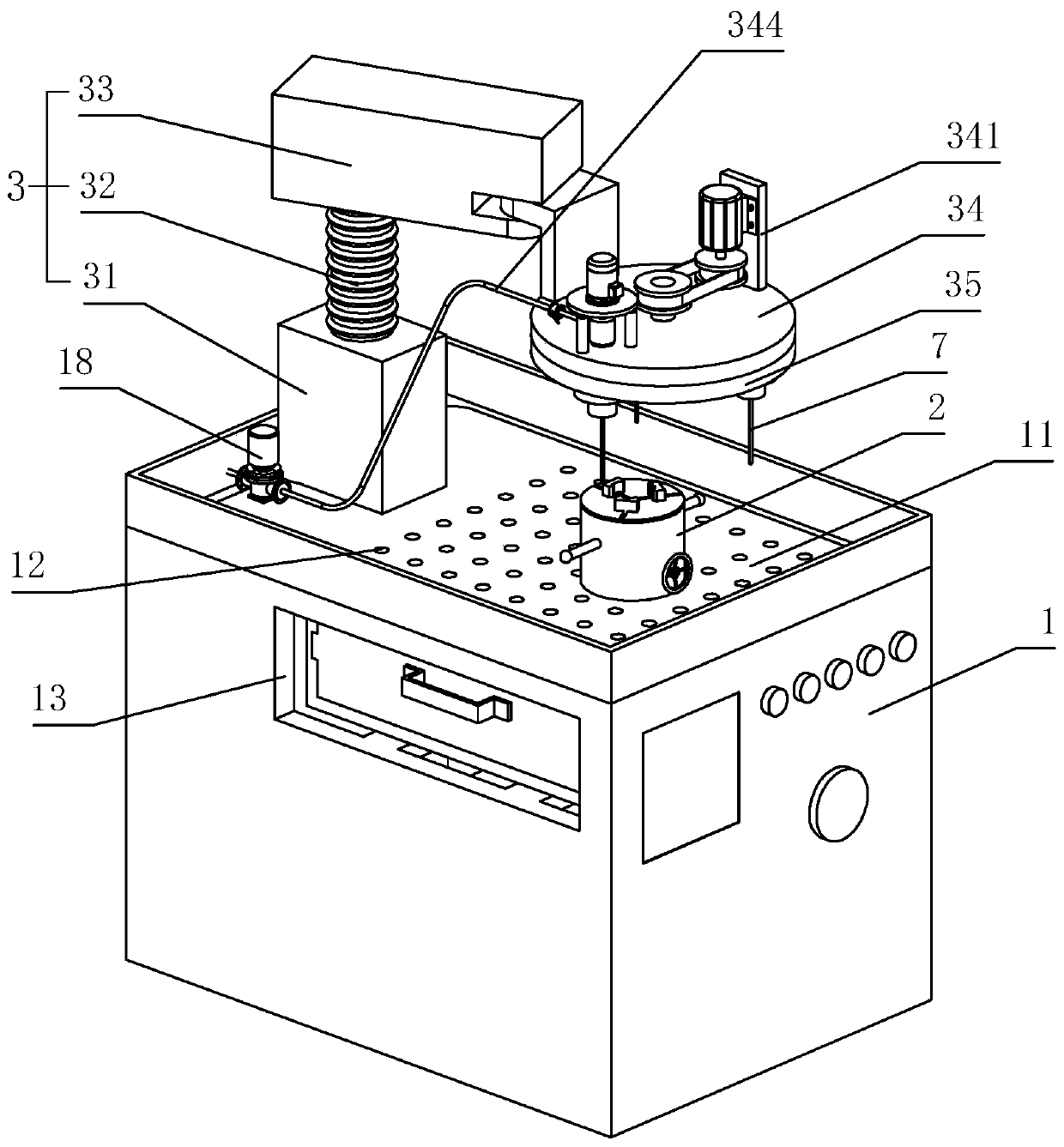

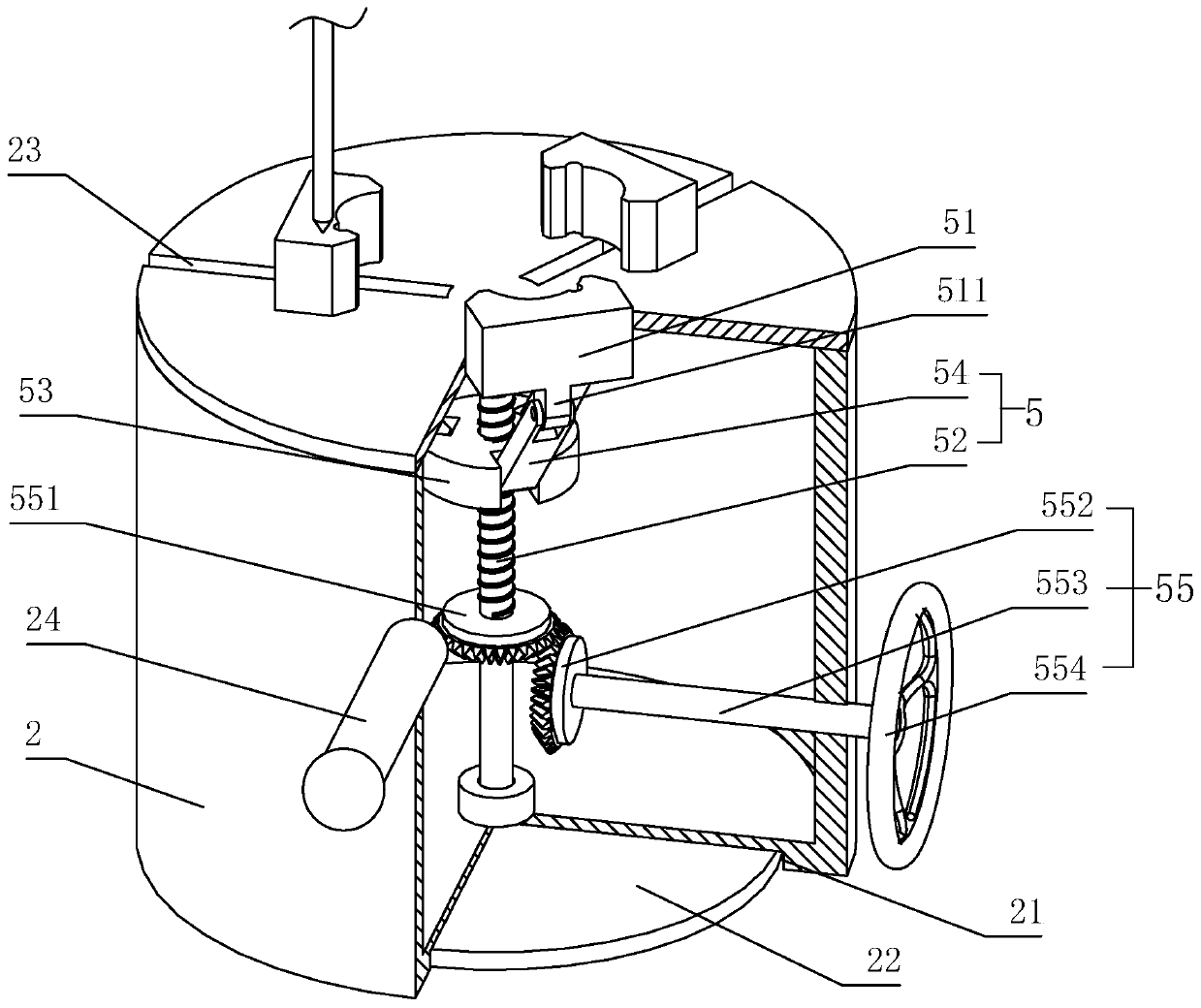

[0047] Example 1, refer to figure 1 , which is a grinding and polishing device for denture processing disclosed in the present invention, comprising a base 1, a cylindrical mounting base 2 mounted on the base 1 and used for fixing the denture during the grinding process, a bracket 3 fixed on the base 1, and a bracket 3 mounted on the base 1. The end of the bracket 3 away from the base 1 is used for grinding the denture 7 .

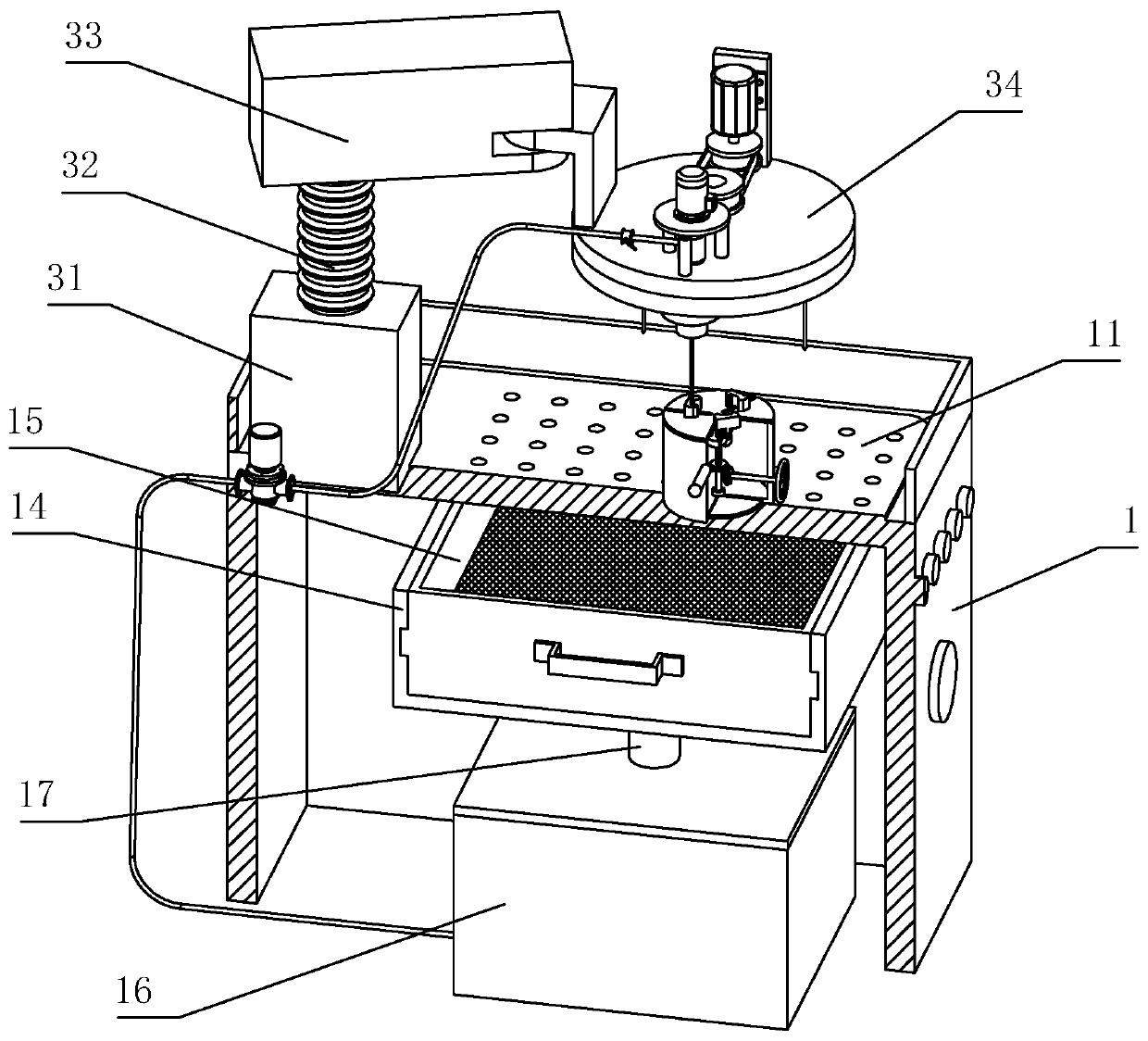

[0048] refer to figure 1 , figure 2 , the upper end surface of the base 1 is provided with a magnetic workbench 11, the upper end surface of the magnetic workbench 11 is provided with a water permeable hole 12 for the residue to fall, the base 1 has a built-in residue collection box 14 for collecting powder residues and is located below the residue collection box 14 The water storage tank 16, the residue collection box 14 is provided with a filter cartridge 15 that is slidingly connected to the residue collection box 14 to filter the powder, and the sid...

Embodiment 2

[0063] Example 2: Reference Figure 5 , the abrasive tool 7 is provided with three groups and is evenly distributed around the axis of the rotating disk 35, each group of abrasive tools 7 includes a rotating seat 71 vertically arranged and rotatably connected to the mounting plate 34 and coaxially connected to the rotating seat 71 to grind the denture. The grinding head 72 is fixedly connected to the rotating seat 71 by bolts, wherein the diameter of the first group of grinding heads 72 is larger than that of the second group of grinding heads 72, and the diameter of the second group of grinding heads 72 is larger than that of the third group of grinding heads 72 The diameter of the head 72. It is convenient to grind different parts of the denture, increase the use range of the device, and improve economic benefits.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com