Internal polishing equipment for stainless steel plate machining

A stainless steel and plate technology, which is applied in the field of internal polishing equipment for stainless steel plate processing, can solve the problems of cumbersome operation and low efficiency, and achieve the effect of ensuring the polishing effect and increasing the polishing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

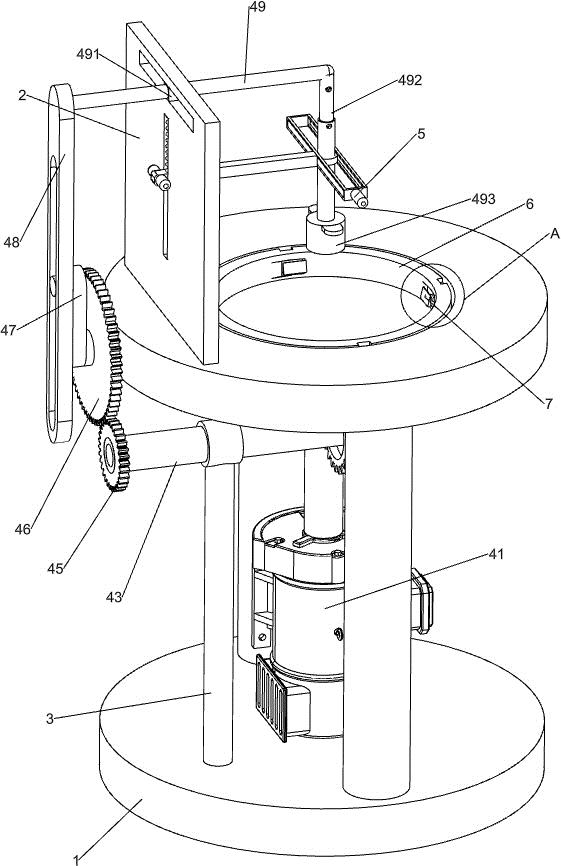

[0023] An in-house polishing equipment for the processing of stainless steel plates, such as figure 1 , figure 2 and Figure 4 As shown, it includes a base 1, a mounting plate 2, a mounting column 3, a movement mechanism 4, a polishing assembly 5 and a turntable 6, the top of the base 1 is connected to the mounting plate 2, the bottom of the base 1 is installed with a mounting column 3, the base 1, the mounting column A motion mechanism 4 is installed between the 3 and the mounting plate 2, a polishing assembly 5 is connected between the mounting plate 2 and the motion mechanism 4, and a turntable 6 is arranged in the middle of the top of the base 1, and the turntable 6 is connected with the motion mechanism 4.

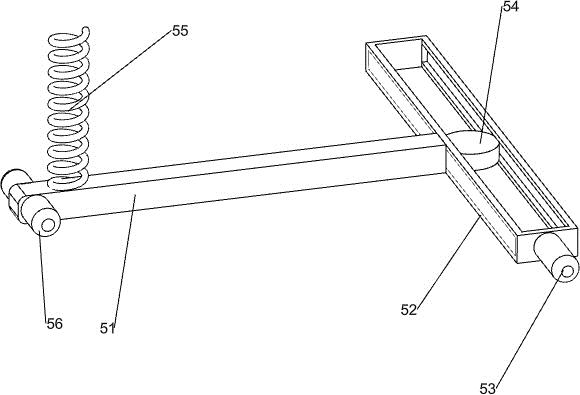

[0024] Motion mechanism 4 comprises motor 41, worm screw 42, first transmission rod 43, worm wheel 44, pinion 45, bull gear 46, first transmission plate 47, second transmission plate 48, second transmission rod 49, first slide block 491, telescopic rod 492 and poli...

Embodiment 2

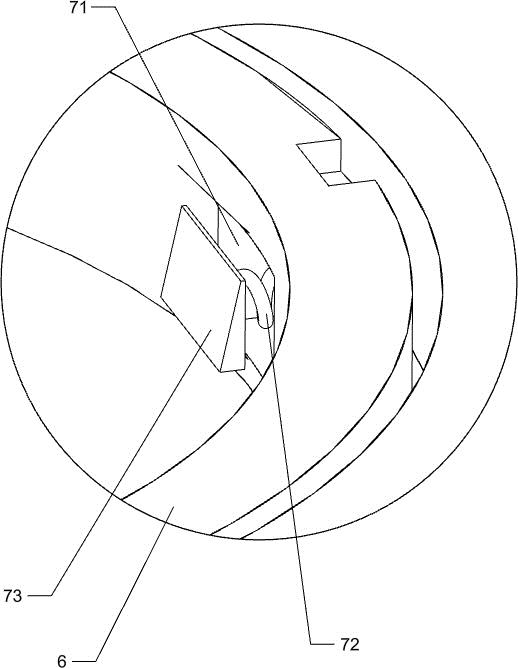

[0028] On the basis of Example 1, such as image 3 As shown, a clamping mechanism 7 is also included, and the clamping mechanism 7 includes a second spring 72 and a splint 73. There are a plurality of reset grooves 71 arranged in the inner circumference of the turntable 6, and a second spring 72 is connected in the reset groove 71. The second spring The tail end of 72 is connected with splint 73 .

[0029] Place the plate between the multiple splints 73, squeeze the plate downwards with your hands, the second spring 72 is compressed, and the splint 73 retracts into the reset groove 71, so that the plate can be fixed by the second spring 72 and the splint 73, Avoid the movement of the plate on the turntable 6 when the plate is being polished, so as to ensure the polishing effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com