Aluminum alloy polishing solution and preparing method thereof

A polishing liquid and aluminum alloy technology, which is applied in the field of polishing, can solve problems affecting the appearance quality of aluminum alloy, difficult ventilation, and restrictions on the promotion of polishing technology, so as to suppress the generation of acid mist, improve the smoothness, and ensure the effect of polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

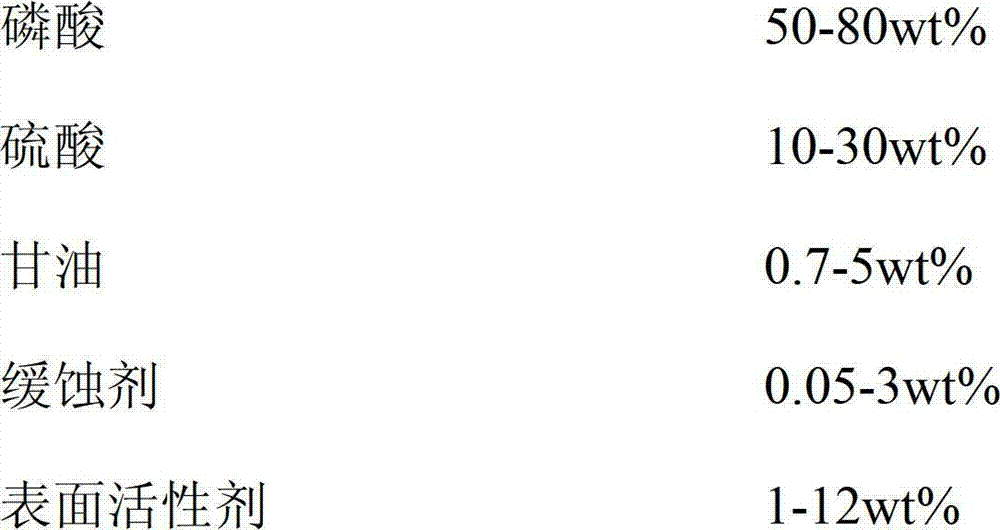

[0050] A polishing liquid comprises the following components by mass percentage:

[0051]

[0052] Wherein, the volume fraction of phosphoric acid is 80%, and the volume fraction of sulfuric acid is 95%;

[0053] The preparation method is:

[0054] Put the formula amount of phosphoric acid into the liquid mixer first, and then put in sulfuric acid, glycerin, thiourea, and dodecylbenzenesulfonic acid in sequence; continue to stir for 10 minutes, and pack the product;

[0055] Instructions:

[0056] The aluminum alloy workpiece is degreased-washed-aluminum alloy polished-water washed-film removal-water washed-dried; wherein, the aluminum alloy polishing temperature is 90°C, and the polishing time is 20s.

Embodiment 2

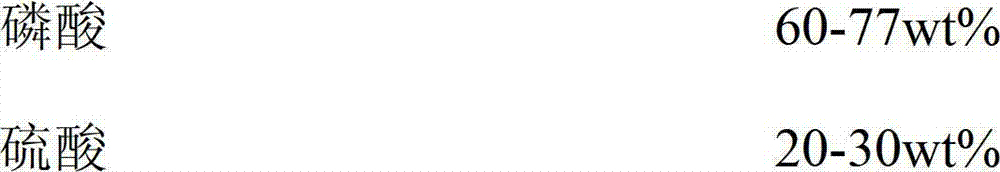

[0058] A polishing liquid comprises the following components by mass percentage:

[0059]

[0060] Wherein, the volume fraction of phosphoric acid is 88%, and the volume fraction of sulfuric acid is 99%;

[0061] The preparation method is:

[0062] Put the formula amount of phosphoric acid into the liquid mixer first, and then put in sulfuric acid, glycerin, BTA, and HF-600 in sequence; continue stirring for 10 minutes, and pack the product;

[0063] Instructions:

[0064] The aluminum alloy workpiece is degreased-washed-aluminum alloy polished-water washed-film-removed-water washed-dried; wherein, the aluminum alloy polishing temperature is 110°C, and the polishing time is 10s.

Embodiment 3

[0066] A polishing liquid comprises the following components by mass percentage:

[0067]

[0068] Wherein, the volume fraction of phosphoric acid is 85%, and the volume fraction of sulfuric acid is 98%;

[0069] The preparation method is:

[0070] Put the formula amount of phosphoric acid into the liquid mixer first, and then put in sulfuric acid, glycerin, Aksu-28, and sodium diphenylamine sulfonate in sequence; continue stirring for 10 minutes, and pack the product;

[0071] Instructions:

[0072] The aluminum alloy workpiece is degreased-washed-aluminum alloy polished-washed-film-removed-washed-dried; wherein, the aluminum alloy polishing temperature is 100°C, and the polishing time is 13s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com