Composite polishing solution and preparation method thereof

A composite polishing and polishing liquid technology, which is applied in chemical instruments and methods, polishing compositions containing abrasives, and other chemical processes, can solve the problems of reducing the polishing effect and rate, hindering the formation of particle clusters, etc., to ensure the polishing effect And the effect of speed and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

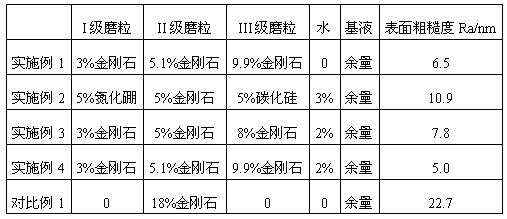

[0038] Configure the polishing liquid, add abrasive grains and water (if necessary) into the base liquid in batches, and continue to ultrasonically disperse during the addition. The average particle size of the Class I abrasive grains is 20 microns; the average particle diameter of the Class II abrasive grains 5 microns; the average particle size of grade III abrasive grains is 2 microns, and the polishing liquid 1~4 is obtained. Put the polishing liquids 1 to 4 in the shear thickening polishing equipment to polish the alumina ceramic curved surface workpiece, use the fixture to clamp the alumina ceramic curved surface workpiece to immerse it in the polishing liquid located in the liquid tank, fix the liquid tank, And the fixture is rotated at a speed of 100r / min, and the treatment time is 30min. The surface roughness Ra of the alumina ceramic curved surface workpiece is 129.6nm before treatment, and the results after polishing are shown in Table 1 below:

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com