Steel plate polishing device for processing metal product

A technology of metal products and polishing devices, which is applied in metal processing equipment, manufacturing tools, grinding/polishing equipment, etc., can solve the problems of limited polishing range, manual adjustment, and reduced polishing operation efficiency, so as to increase the efficiency of grinding and polishing. Range, guaranteed polishing effect, easy and fast lifting operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

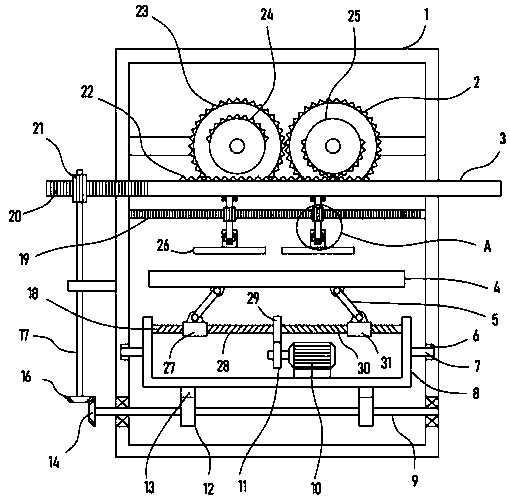

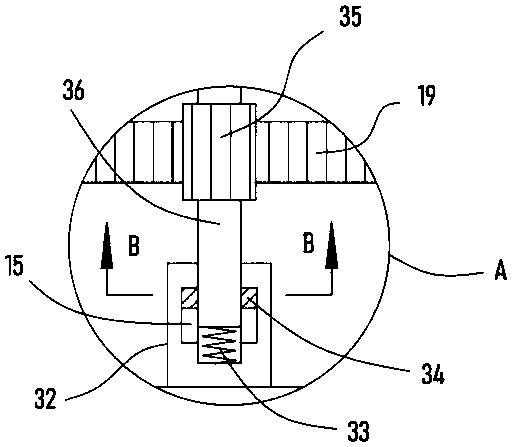

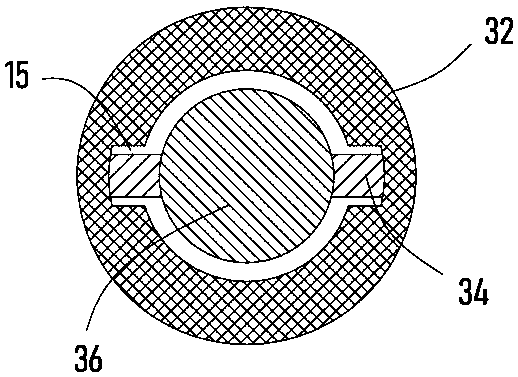

[0021] see Figure 1-3 , a steel plate polishing device for metal product processing, including a support frame 1, a bearing frame 8 is arranged in the support frame 1, a support plate 4 is installed on the support frame 8, and the set support plate 4 is used to place the steel plate to be polished.

[0022] The support frame 1 is horizontally slidable and is provided with a slide plate 3 , the upper rack 22 is fixed on the slide plate 3 , and the drive gear I2 and the drive gear II23 which are connected to each other in the support frame 1 are rotatably provided, and the drive gear I2 and the drive gear II23 An incomplete gear I24 and an incomplete gear II25 are respectively coaxially fixed on the top, and the upper rack 22 meshes with the incomplete gear I24 or the incomplete gear II25.

[0023] The transmission gear II23 is connected with a driving motor, the transmission gear II23 is coaxially fixed with the output shaft of the driving motor, the transmission gear II23 dri...

Embodiment 2

[0028] On the basis of Embodiment 1, in addition, a transmission rack 20 is fixed on the slide plate 3, and a cylindrical spur gear I21 engaged with it is rotatably provided on the transmission rack 20, and a rotating shaft 17 is coaxially fixed on the cylindrical spur gear I21. The lower end of the rotating shaft 17 is coaxially fixed with a driving bevel gear 16, the bottom of the driving bevel gear 16 is provided with a driven bevel gear 14 meshing with it, and the driven bevel gear 14 is coaxially fixed with a driven shaft 9 located below the bearing frame 8. A connecting gear 12 is sheathed on the driven shaft 9 , and a connecting rack 13 meshing with the connecting gear 12 is fixedly mounted on the bottom of the bearing frame 8 .

[0029] The slide plate 3 and the transmission rack 20 reciprocate left and right, and the transmission rack 20 drives the rotating shaft 17 to alternately rotate counterclockwise through the cylindrical spur gear 121 meshed with it, and then re...

Embodiment 3

[0032] On the basis of Embodiment 2, in addition, the bearing frame 8 is provided with an adjustment shaft 18 in a rotating manner, and the surface of the adjustment shaft 18 is tapped with a first external thread 28 and a second external thread 30 with symmetrical positions and opposite rotation directions. The shaft 18 is sleeved with a threaded sleeve I27 threaded with the first external thread 28 and a threaded sleeve II31 threaded with the second external thread 30, and the threaded sleeve I27 and the threaded sleeve II31 are hinged to the support plate 4 A support rod 5 is arranged, and the upper end of the support rod 5 is hinged on the lower surface of the support plate 4 .

[0033] Further, the forward and reverse motor 10 is fixedly installed in the bearing frame 8, the output shaft of the forward and reverse motor 10 is fixedly installed with the drive gear 11, and the surface of the adjustment shaft 18 is sleeved and fixedly installed with a slave gear meshed with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com