Grinding and polishing method of metal strip

A technology for metal strips and abrasive brushes, which is applied to polishing compositions containing abrasives, grinding devices, grinding machine tools, etc., and can solve problems such as large specificity of imported brush rollers and overcapacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Copper strip: C10200, 0.5mm thick; coil weight: 4 tons

[0026] Experimental method: online grinding

[0027] Grinding brush: ordinary canvas brush is used in the invention example (the canvas has a rectangular structure, and its overlapping is set on the surface of the Bakelite cylinder)

[0028] Grinding effect evaluation symbols: ◎-good ○-good ▲-poor

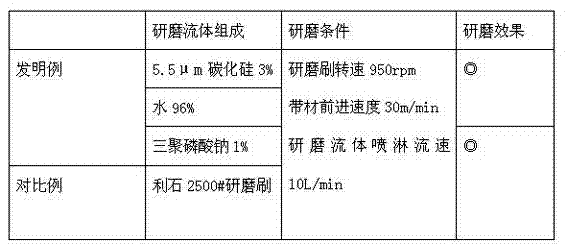

[0029] Table 1

[0030]

[0031] Table 1 shows that: using the abrasive fluid of Example 1 to grind and polish a copper strip with a thickness of 0.5 mm, the same effect as that of the abrasive brush in the comparative example is obtained, but the cost is reduced by 30%.

[0032] The grinding brush in this embodiment 1 can adopt non-woven fabric, fleece, nylon, damping cloth or neoprene cloth, also can reach the technical effect identical with embodiment 1 at last.

Embodiment 2

[0034] Copper strip: tin phosphor bronze strip C5191, 0.2mm thick; coil weight: 4 tons

[0035] Experimental method: online grinding

[0036] Abrasive brush: In the example of the invention, ordinary non-woven brushes are used (ordinary non-woven fabrics have a ring structure, and their sockets are set on the surface of the bakelite cylinder)

[0037] Grinding effect evaluation symbols: ◎-good ○-good ▲-poor

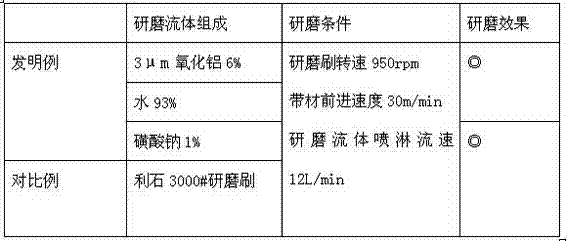

[0038] Table 2

[0039]

[0040] Table 2 shows that: using the abrasive fluid of Example 2 to grind and polish the tin phosphor bronze strip with a thickness of 0.2 mm, the same effect as that of the abrasive brush in the comparative example is obtained, but the cost is reduced by 40%.

[0041] In the above formula, the diamond powder is replaced by a mixture of one or more of silicon dioxide, aluminum oxide, cerium oxide, silicon carbide and cubic boron nitride, and the particle size of the diamond powder is 0.5 μm, 1 μm, 3 μm, 6 μm, 20 μm or 40 μm, can also achiev...

Embodiment 3

[0044] Copper strip: zinc white copper C7025, 0.16mm thick; coil weight: 4 tons

[0045] Experimental method: online grinding

[0046] Grinding brush: ordinary nylon brush is used in the invention example

[0047] Grinding effect evaluation symbols: ◎-good ○-good ▲-poor

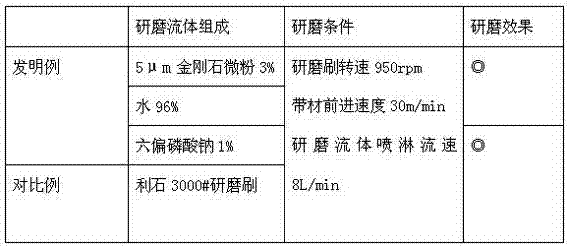

[0048] table 3

[0049]

[0050] Table 3 shows that using the abrasive fluid of Example 3 to grind and polish the zinc-nickel-nickel copper strip with a thickness of 0.2 mm, the same effect as that of the abrasive brush in the comparative example is obtained, but the cost is reduced by more than 30%.

[0051] Sodium sulfonate adopts sodium phosphate, sodium tripolyphosphate, sodium hexametaphosphate, sodium acrylate or other low-foaming dispersion emulsifiers in this embodiment, also can reach the technical effect identical with embodiment 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com