Outer surface flexibility polishing device of motor rotor

A motor rotor and outer surface technology, applied in grinding/polishing equipment, metal processing equipment, machine tools with surface polishing, etc., can solve problems such as physical damage to workers, a large amount of dust, etc., to improve work efficiency, uniform loss, and improve quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

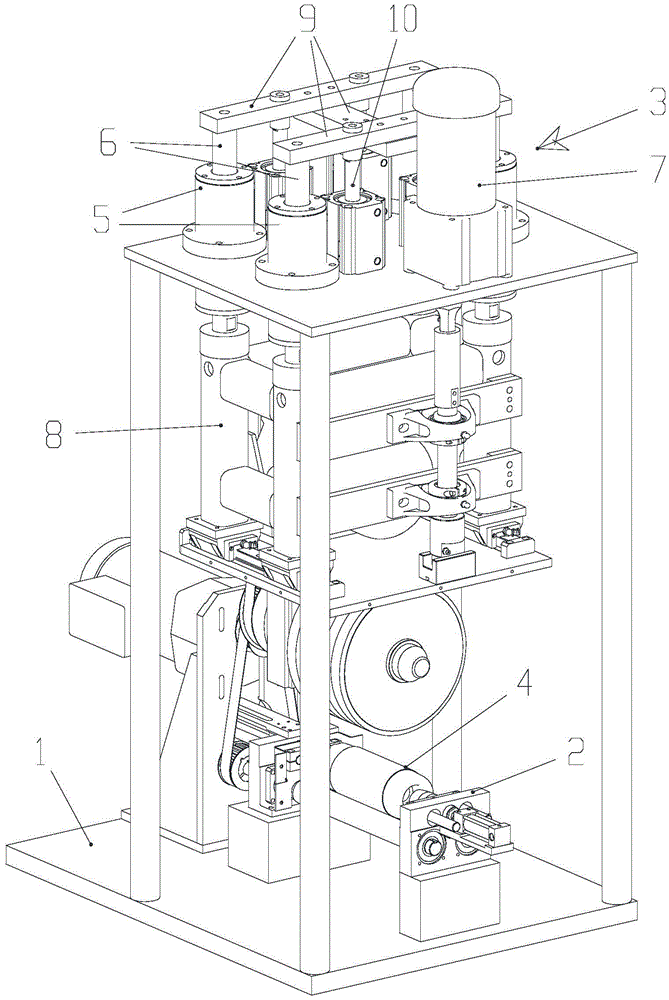

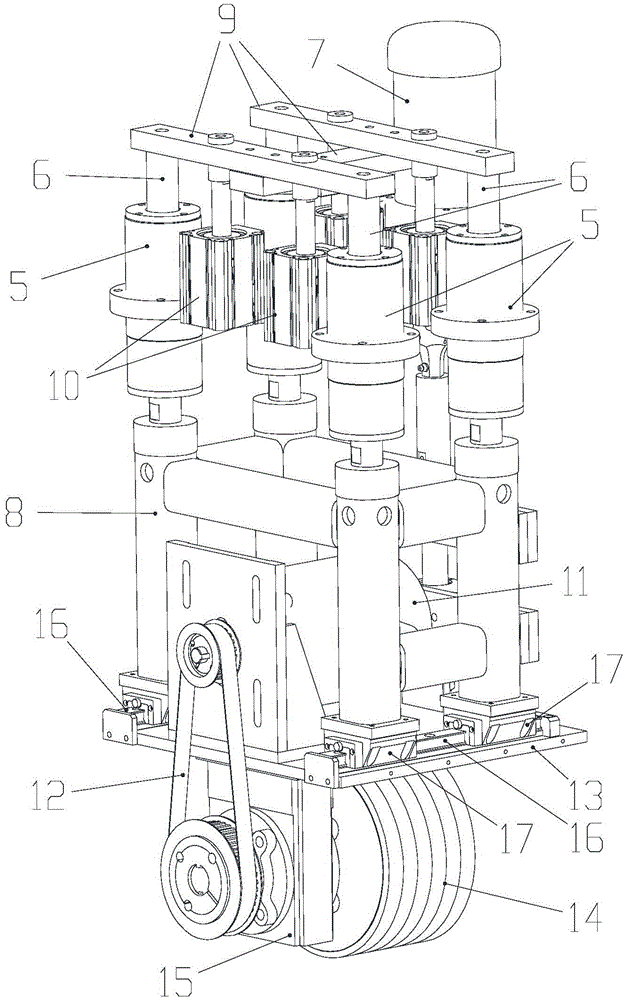

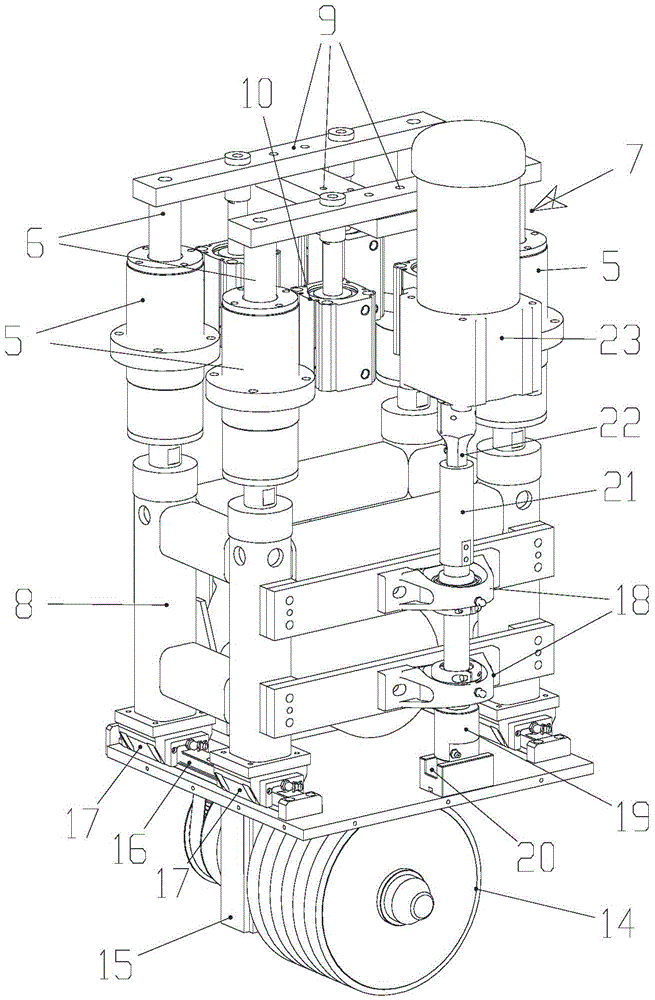

[0032] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. As mentioned above, the present invention provides a flexible grinding device for the outer surface of the motor rotor, which is used for grinding and polishing the outer surface of the motor rotor. The flexible grinding device for the outer surface of the motor rotor of the present invention has good manufacturability and can automatically clamp the motor rotor And drive the motor rotor to rotate at a certain speed. The hemp wheel used for grinding has the function of high-speed rotation and movement along the axial direction of the motor rotor, which greatly improves the quality and efficiency of grinding.

[0033] The invention provides a flexible grinding device for the outer surface of a motor rotor, comprising: a large bracket 1, an automatic fixture 2 for installing a motor rotor 4, a flexible grinding mechanism 3 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com