Automatic polish-grinding system and automatic polish-grinding process for thin-wall stamping part

A stamping, thin-walled technology, used in manufacturing tools, other manufacturing equipment/tools, manipulators, etc., can solve the problem of inability to completely remove surface flaws or defects on the workpiece, unfavorable high efficiency, high-quality production, and inability to ensure grinding pressure. and other problems, to improve the grinding and polishing effect, improve production efficiency and product quality, and solve the effect of poor surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to better understand the patent of the present invention, the following describes the patent of the present invention with reference to the drawings and specific embodiments.

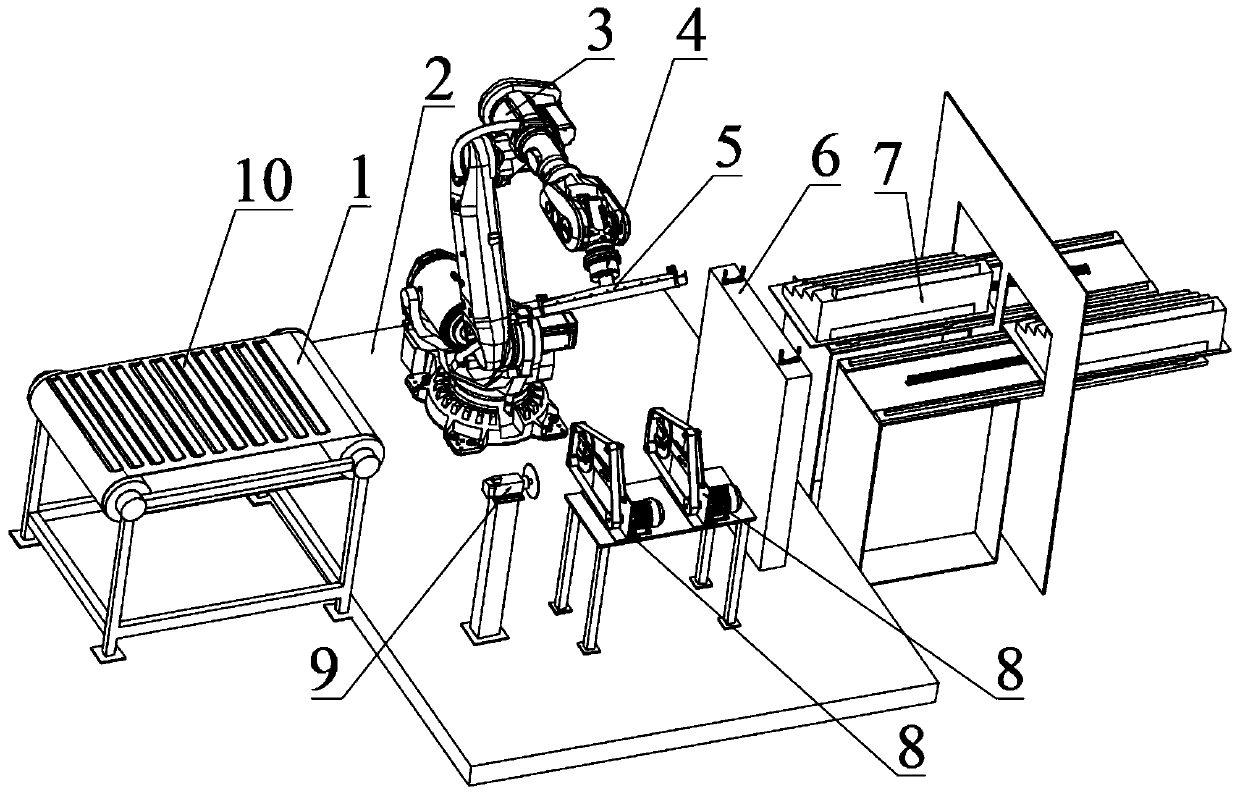

[0044] Such as figure 1 Shown is a schematic diagram of the overall structure of the automatic grinding and polishing system of the present invention, including conveyor belt 1, base 2, industrial robot 3, force control sensor 4, pneumatic clamp 5, lock seat 6, automatic feeding device 7, sanding belt machine 8, and Slicer 9. The industrial robot 3 is installed on the mounting base 2. The six-axis end of the industrial robot 3 is equipped with a force control sensor 4, and a pneumatic clamp 5 is installed under the force control sensor 4; the motor of the slicer 9 is equipped with a saw blade and two sand The belt conveyor 8 is respectively equipped with a narrow belt with coarse sand and a wide belt with fine sand. The automatic feeding device 7 and the conveyor belt 1 are respectively arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com