Cold rolling process for 304 stainless steel 2B base material for decorative panel

A 304 stainless steel, decorative panel technology, used in abrasives, rolls, metal rolling, etc., can solve the problems of high production cost, low processing efficiency, complex production process, etc., achieve less defect coverage, improve processing efficiency, and rough surface. low degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of cold-rolling process of 304 stainless steel 2B base material for decorative panel, specifically comprises the following steps:

[0028] a. Solution treatment: continuous annealing is carried out on the hot-rolled black coil, and the annealing temperature is 1080°C to obtain a solid solution stainless steel coil;

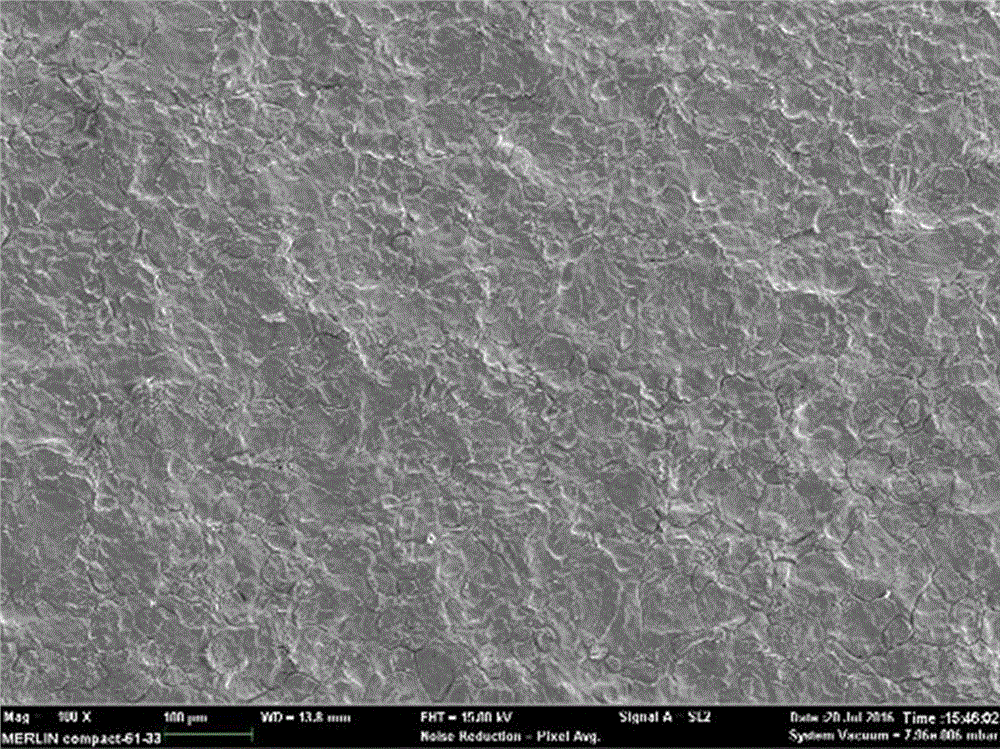

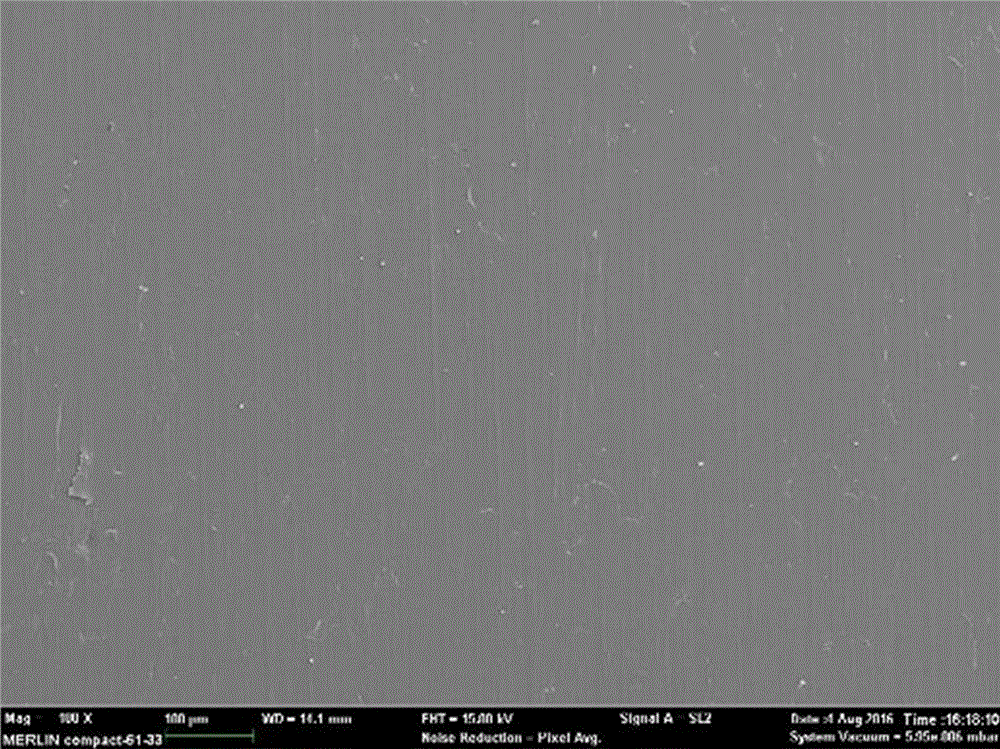

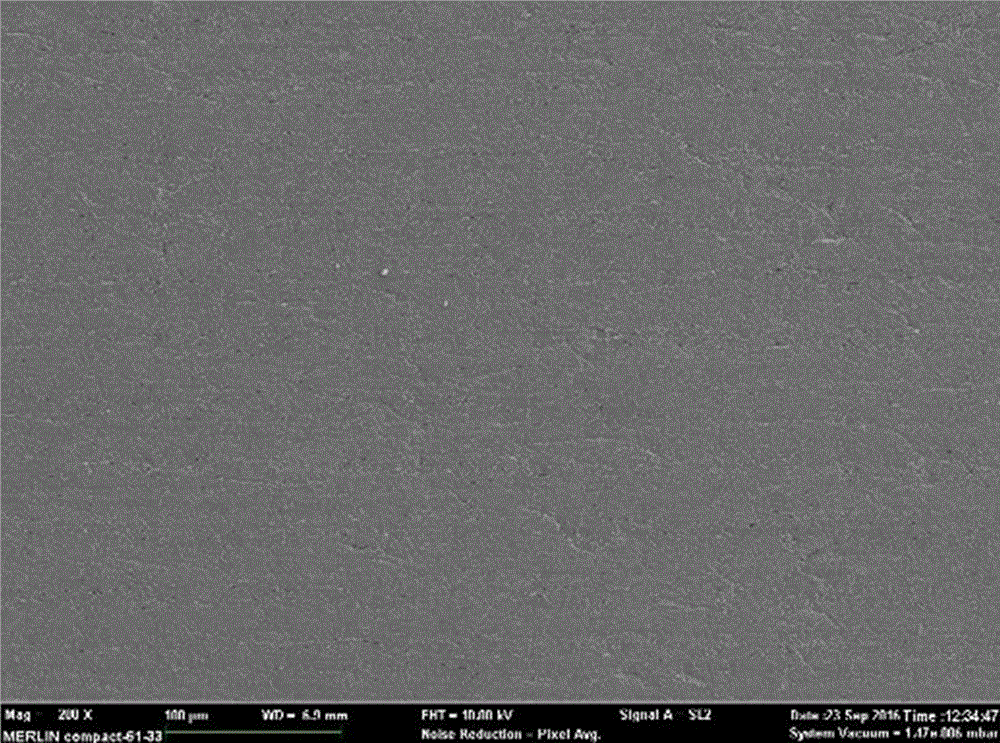

[0029] b. On-line pickling: adopt the continuous pickling process of scale breaking-shot blasting-sulfuric acid pre-pickling-mixed acid pickling to pickle the solid solution stainless steel in step a to obtain hot-rolled annealed and pickled stainless steel, broken The elongation rate of the scale machine is 1.5%. The shot blasting machine uses cast shot with a particle size of 400 μm and steel wire cut shot with a particle size of 800 μm. The mixing ratio of cast shot and steel cut shot used in the shot blasting machine is 2: 1. The throwing speed is 40m / s, and the pellet flow rate is 10kg / m 2 , the concentration of sulfuric acid in the sulfuric ac...

Embodiment 2

[0038] A kind of cold-rolling process of 304 stainless steel 2B base material for decorative panel, specifically comprises the following steps:

[0039] a. Solution treatment: continuous annealing is carried out on the hot-rolled black coil, and the annealing temperature is 1090°C to obtain a solid solution stainless steel coil;

[0040] b. On-line pickling: adopt the continuous pickling process of scale breaking-shot blasting-sulfuric acid pre-pickling-mixed acid pickling to pickle the solid solution stainless steel in step a to obtain hot-rolled annealed and pickled stainless steel, broken The elongation rate of the scale machine is 1.5%. The cast shot with a particle size of 400 μm and the steel cut shot with a particle size of 800 μm used in the shot blasting machine are mixed. The mixing ratio of the cast shot and steel cut shot used in the shot blasting machine is 1: 1. The throwing speed is 60m / s, and the shot flow rate is 11kg / m 2 , the concentration of sulfuric acid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com