Precious stone polishing machine

A ball machine, gemstone technology, applied in surface polishing machine tools, machine tools suitable for grinding workpiece edges, grinders, etc. The effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

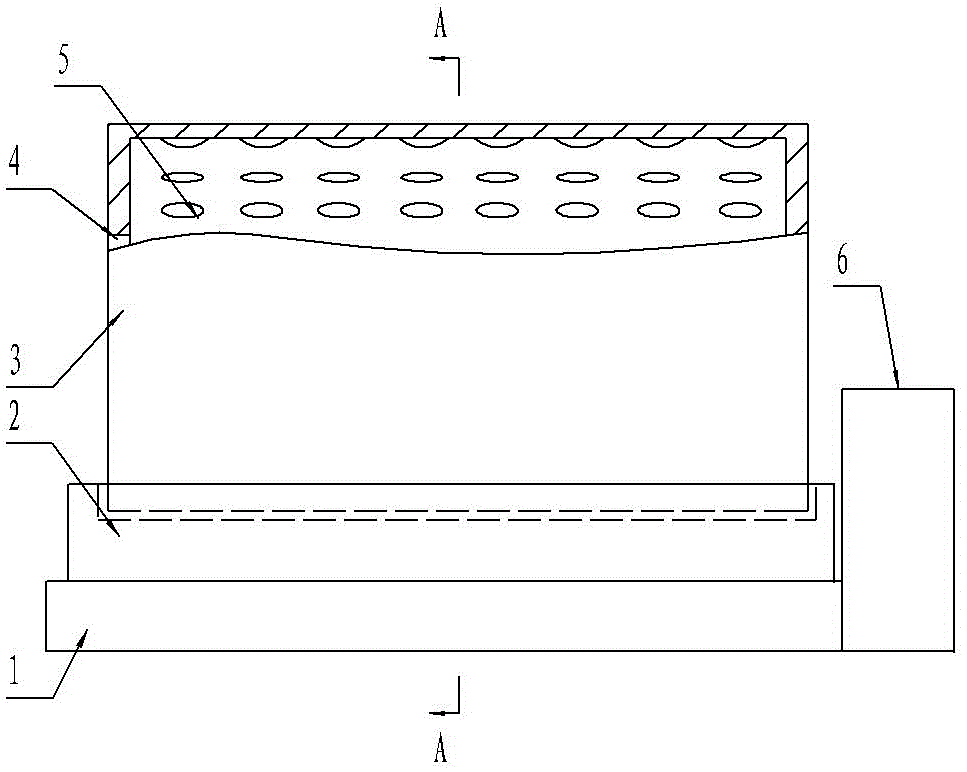

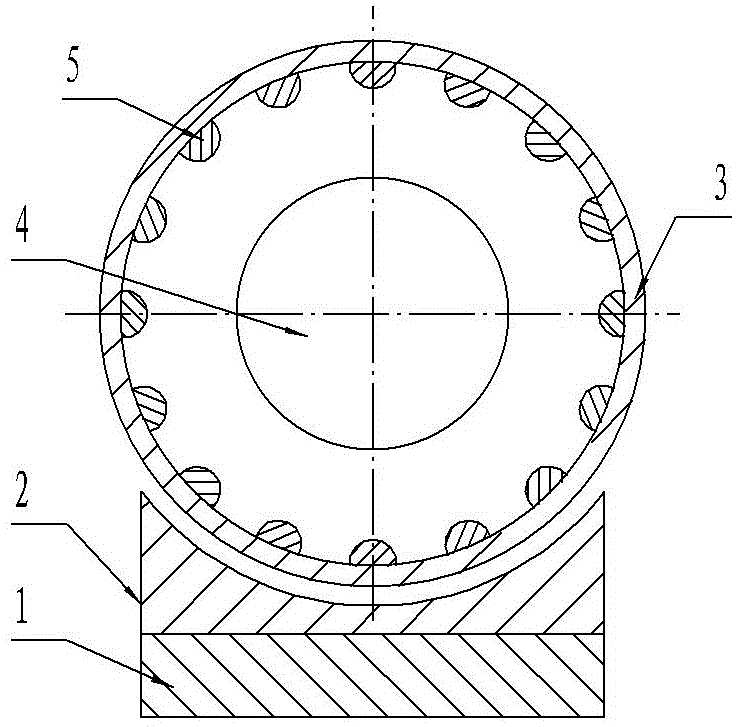

[0011] Such as figure 1 , figure 2 The jewel ball machine shown includes a horizontally arranged cylinder 3, a recess 2 is provided under the cylinder 3, the upper end surface of the recess 2 is recessed, and a base 1 for supporting the recess 2 is provided under the recess 2.

[0012] Both the drum 3 and the recess 2 are electromagnets, and the directions of the electromagnetic poles of the drum 3 and the recess 2 are opposite. Both the drum 3 and the recess 2 are connected with the electrical control box 6, and the drum is driven to rotate on the recess by electromagnetic force, which greatly saves The electric energy is absorbed, and the drum rotates smoothly.

[0013] There are multiple protrusions 5 on the inner wall of the drum 3, and the protrusions 5 are elongated protrusions, which can make the beads or strips rub against the protrusion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com