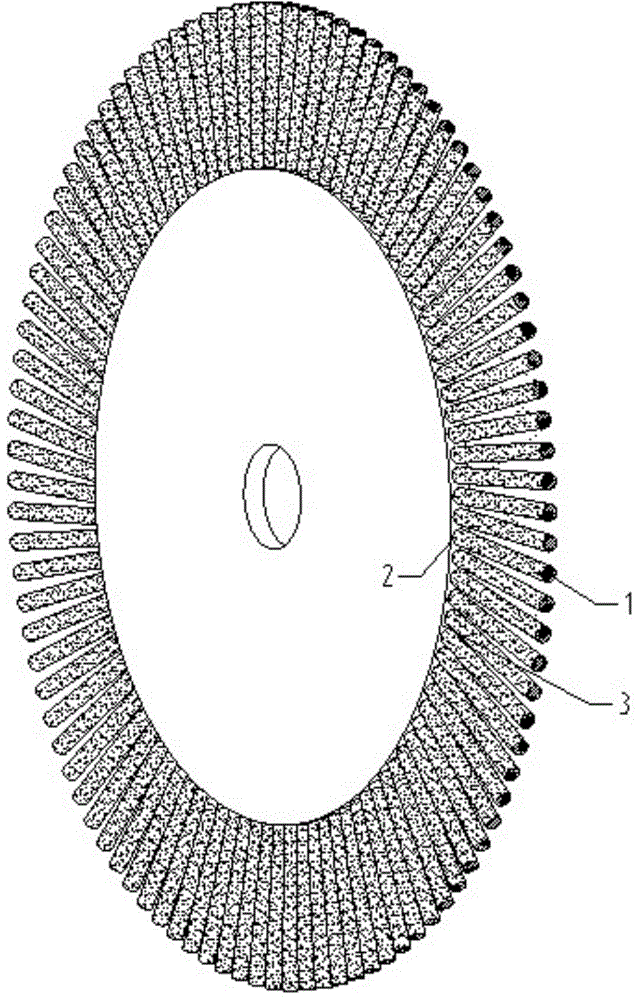

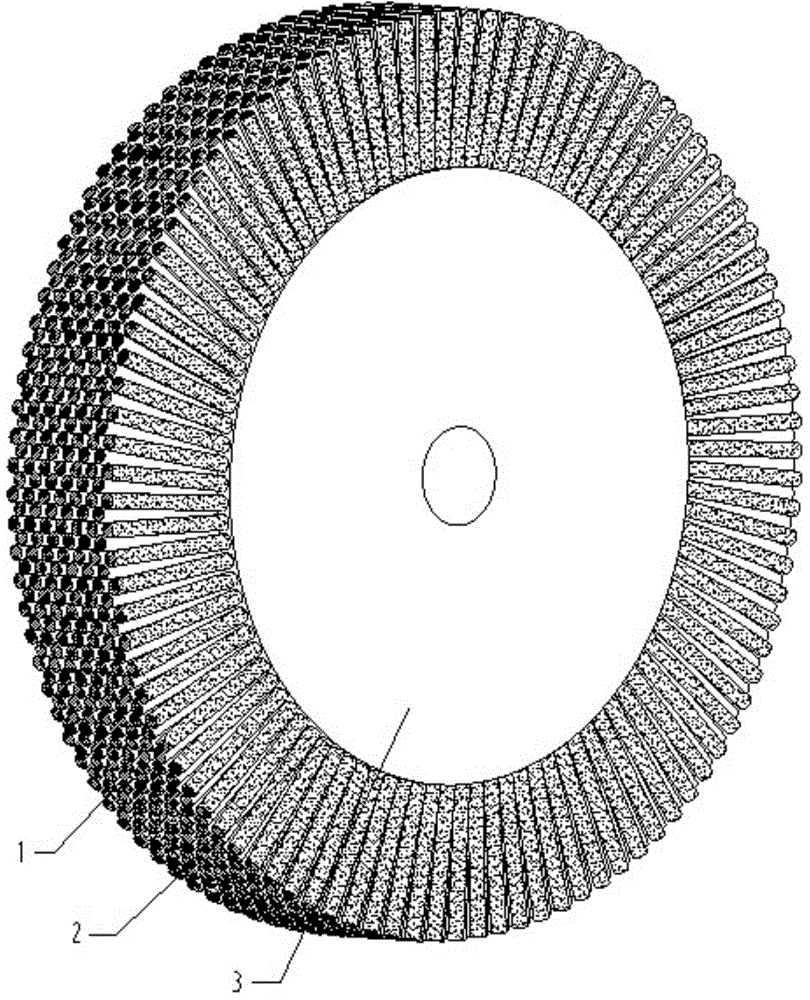

Polishing wheel based on fiber adhesive rope coated abrasive tool

A technology of coating abrasive tools and polishing wheels, which is applied in the field of polishing wheels, can solve the problems of polluting the surface of the workpiece to be ground, poor tear resistance, and no grinding, etc., to reduce the cost of the grinding and polishing process, reduce the manufacturing cost, The effect of high grinding and polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

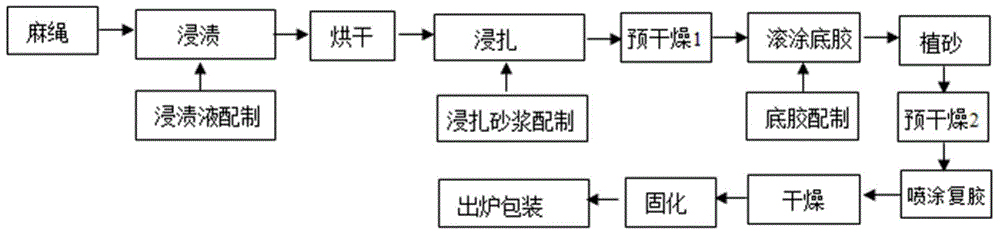

[0029] 1. Production of sand rope:

[0030] 1.1 Impregnation treatment of sisal fiber rope: (diameter of sisal fiber rope is 2-5mm) use polyvinyl alcohol aqueous solution with a mass fraction of 15%-20%, soak the sisal fiber rope at 90±2°C for 10min, then use double rollers Tie-car extrusion, control the wet sizing at 20% ± 2%; dry the soaked and extruded sisal fiber rope at 70 ± 2°C to constant weight.

[0031] 1.2 Mortar impregnation: impregnate the impregnated sisal rope with prepared mortar. (The mortar is: modified liquid phenolic resin solution 35%, abrasive: 45%, filler: 15%, thinner: 5%, mortar solid content: 75-77%, slurry amount: per gram of sisal 0.7-0.8g on fiber rope); then bake at 80±2°C for 60min.

[0032] 1.3 Roll a circle of primer on the dipped sisal fiber rope (the primer is : modified liquid phenolic resin solution 65%, filler: 35%, glue solid content: 75-77%, glue The amount is: 0.7-0.8g per gram of sisal fiber rope); after rolling the primer, use the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com