Metallographic phase polishing solution automatic feeding machine

A polishing liquid and feeding machine technology, applied in grinding/polishing equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of uncertain liquid output, hidden safety hazards, troublesome operation, etc., to avoid corrosion problems and reduce usage. Cost, easy operation and direct effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

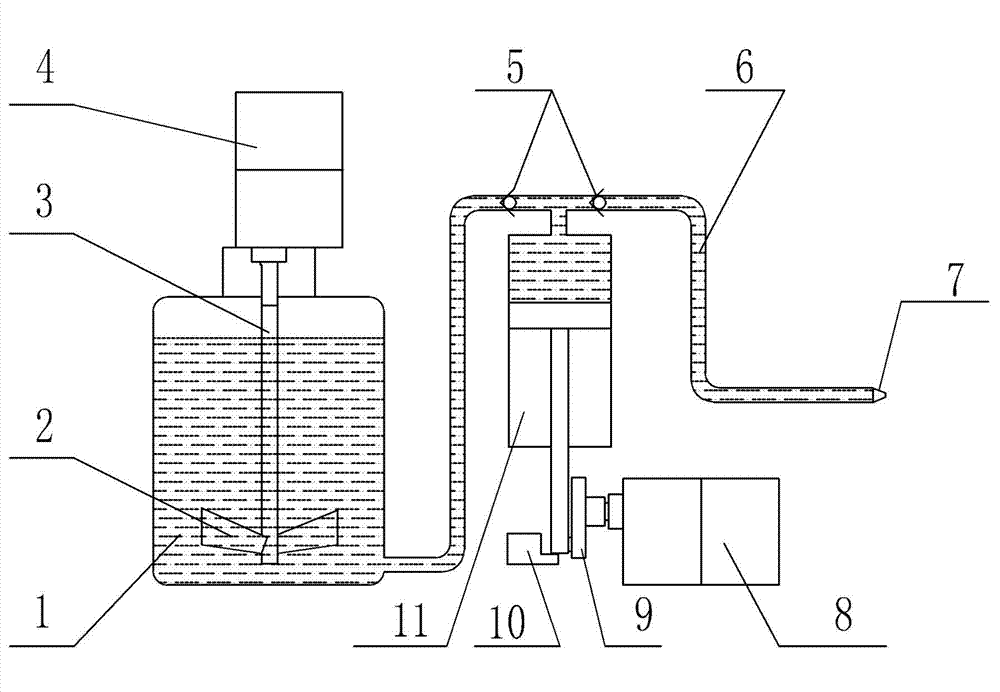

[0026] Such as figure 1 As shown, this metallographic polishing liquid automatic supply machine is composed of stirring motor 4, liquid storage cylinder 1, stirring shaft 3, blade 2, liquid pump motor 8, plunger liquid pump 11, one-way valve 5, connecting conduit 6, outlet The liquid end nozzle 7 is composed of a single-chip microcomputer. The upper part of the liquid storage cylinder 1 is equipped with a stirring motor 4. The output end of the stirring motor is connected with the stirring shaft 3. The lower end of the stirring shaft is equipped with a blade 2. The output end of the liquid pump motor 8 is connected with the cam. 9, the cam 9 is connected with the piston of the plunger liquid pump 11, the cylinder of the plunger liquid pump 11 is connected with the liquid storage cylinder 1 and the nozzle 7 of the liquid outlet through the connecting conduit 6, and the plunger liquid pump 11 A one-way valve 5 is arranged on the connecting conduits 6 at both ends respectively co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com