Grinding system of casting machine

A casting machine and grinding table technology, which is applied in the direction of manufacturing tools, grinding workpiece supports, grinding drive devices, etc., can solve the problems that dust cannot be processed, the efficiency of grinding treatment is poor, and the quality of work is affected, so as to improve the grinding and polishing effect , Grinding evenly, high efficiency of grinding treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

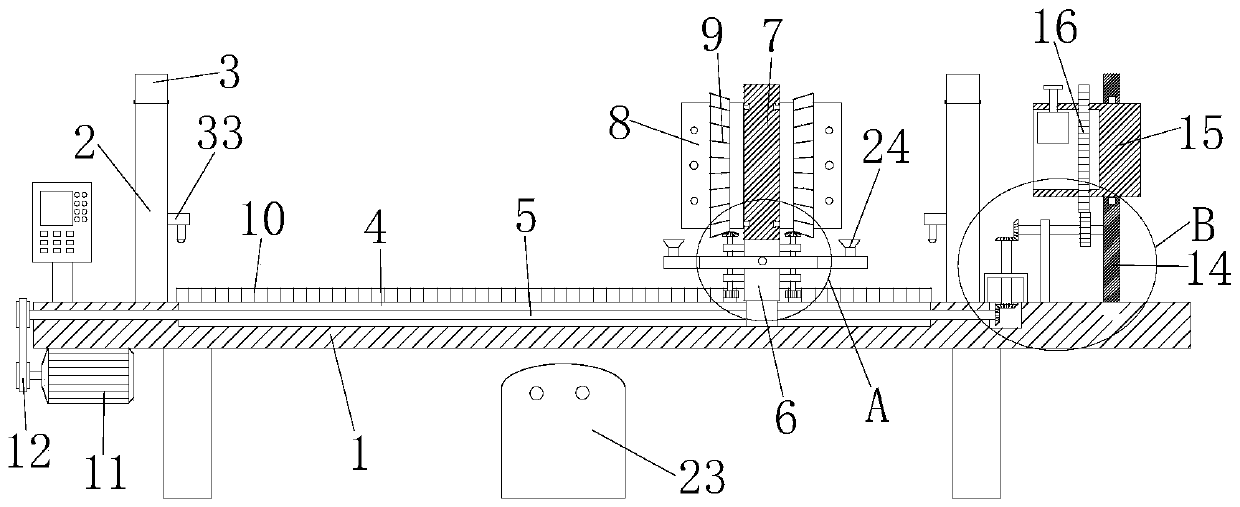

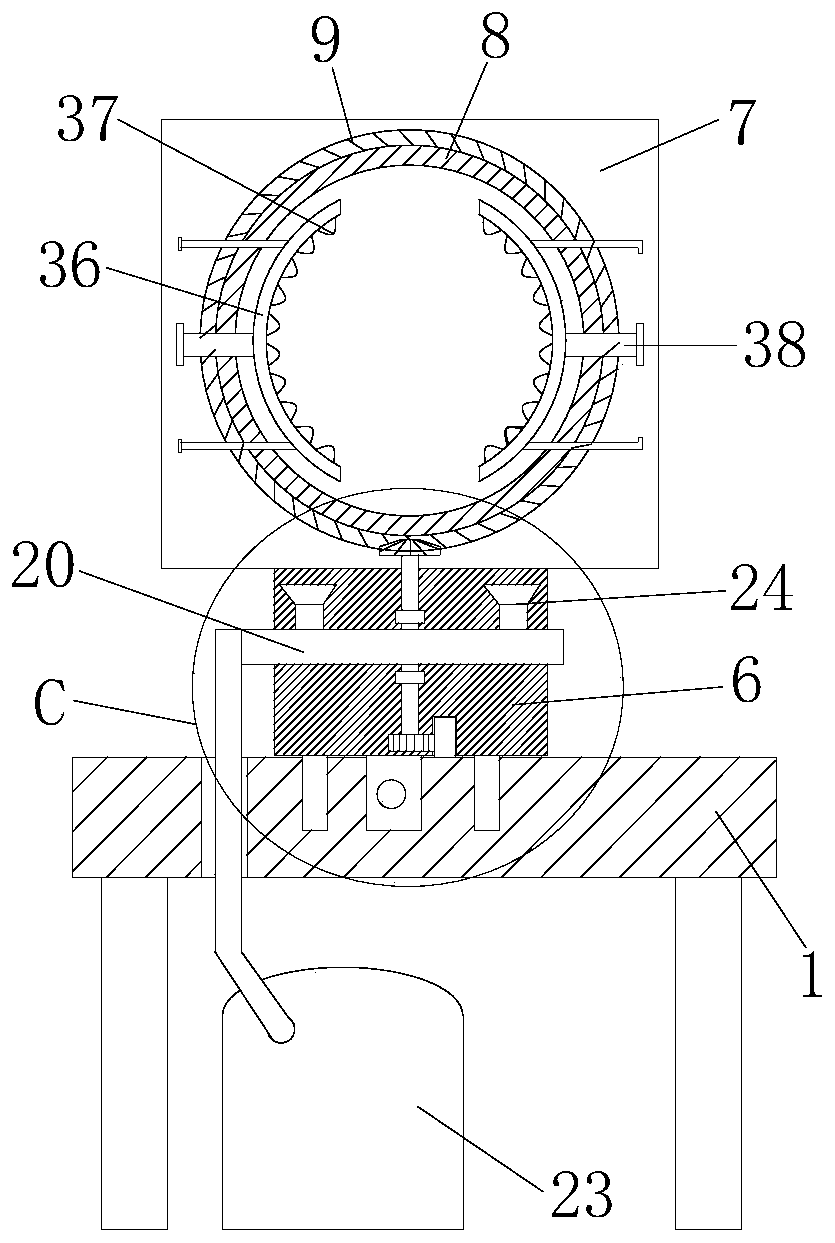

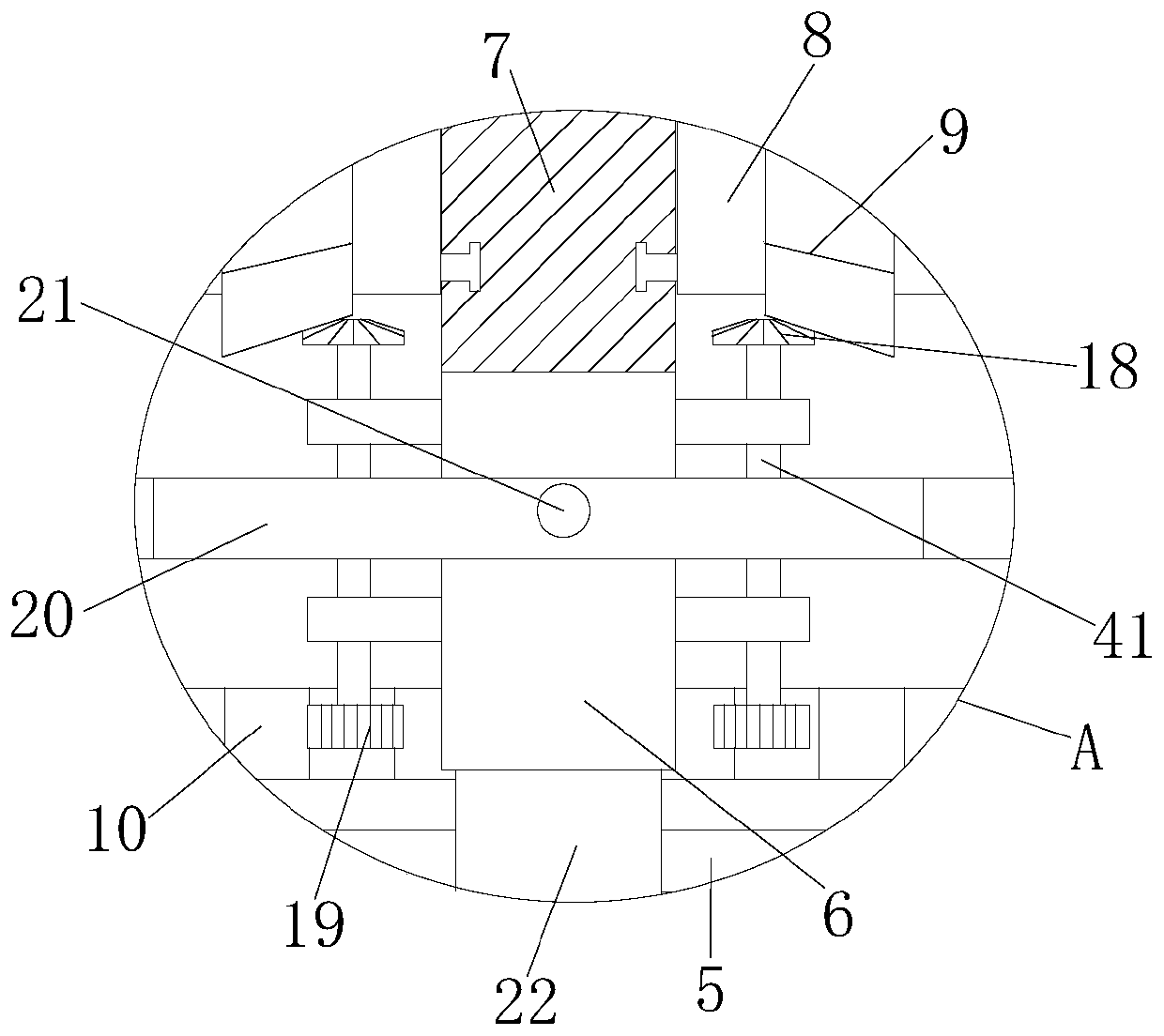

[0047] refer to Figure 1-8 , a casting mechanical grinding system, comprising a grinding table 1, two supports 2 are fixedly installed on the top of the grinding table 1 by welding, and a turning part 3 is installed on the two supporting parts 2, and the supporting part 2 and the turning part 3 A plurality of guide cylinders 40 are installed rollingly between them, a groove 4 is provided on the top of the grinding table 1, a screw rod 5 is installed in the groove 4, and a servo motor 11 and a screw rod 5 are fixedly connected to the bottom of the grinding table 1 by screws. Cooperating with the servo motor 11, the screw rod 5 is screwed with a sliding block 22, the sliding block 22 is slidingly connected with the groove 4, the top of the sliding block 22 is fixedly installed with a moving plate 6 by welding, and the top of the moving plate 6 is fixed by welding A fixed plate 7 is installed, and both sides of the fixed plate 7 are rotatably equipped with a rotating cylinder 8....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com