Composite grinding and polishing method and device

A technique for polishing and CNC machine tools, which is applied in the direction of grinding devices, grinding machine tools, grinding tools, etc. It can solve the problems of a single magnetic field application device, difficult control, and cumbersome procedures, so as to improve productivity and surface quality, improve processing efficiency, The effect of high response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

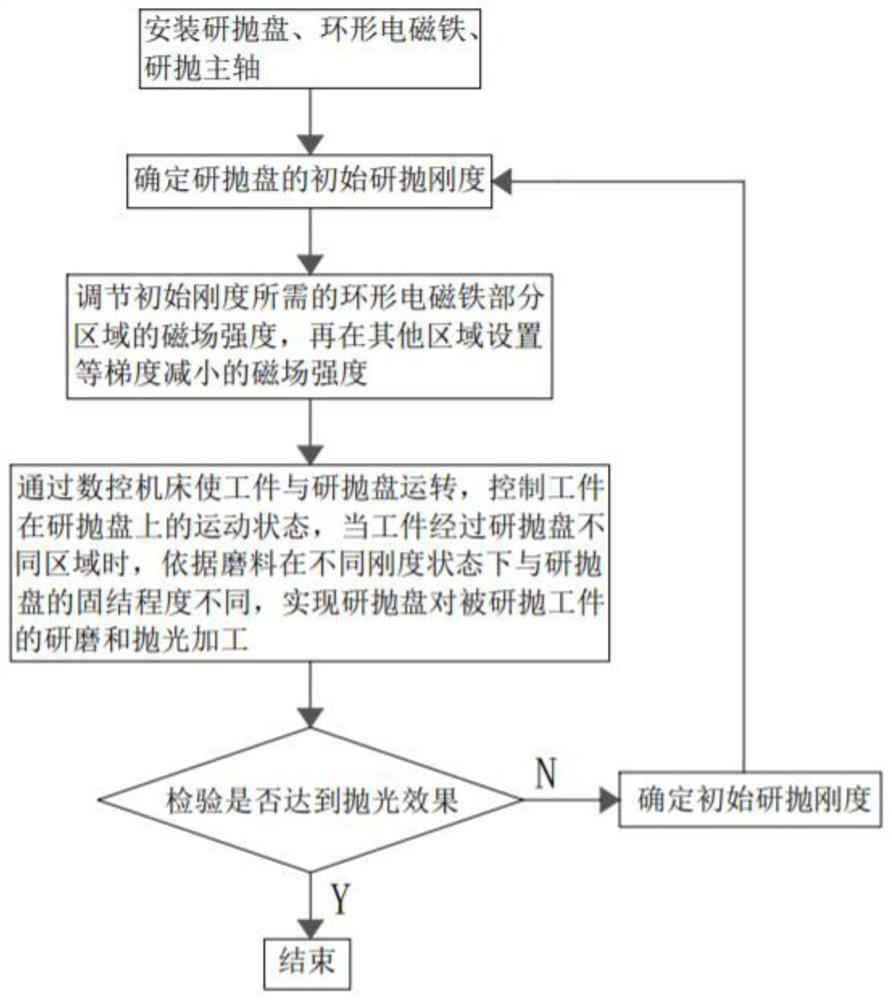

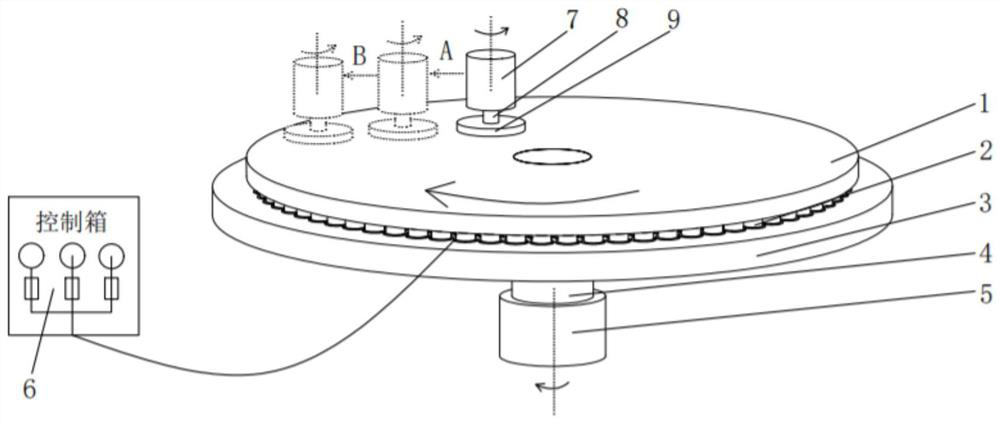

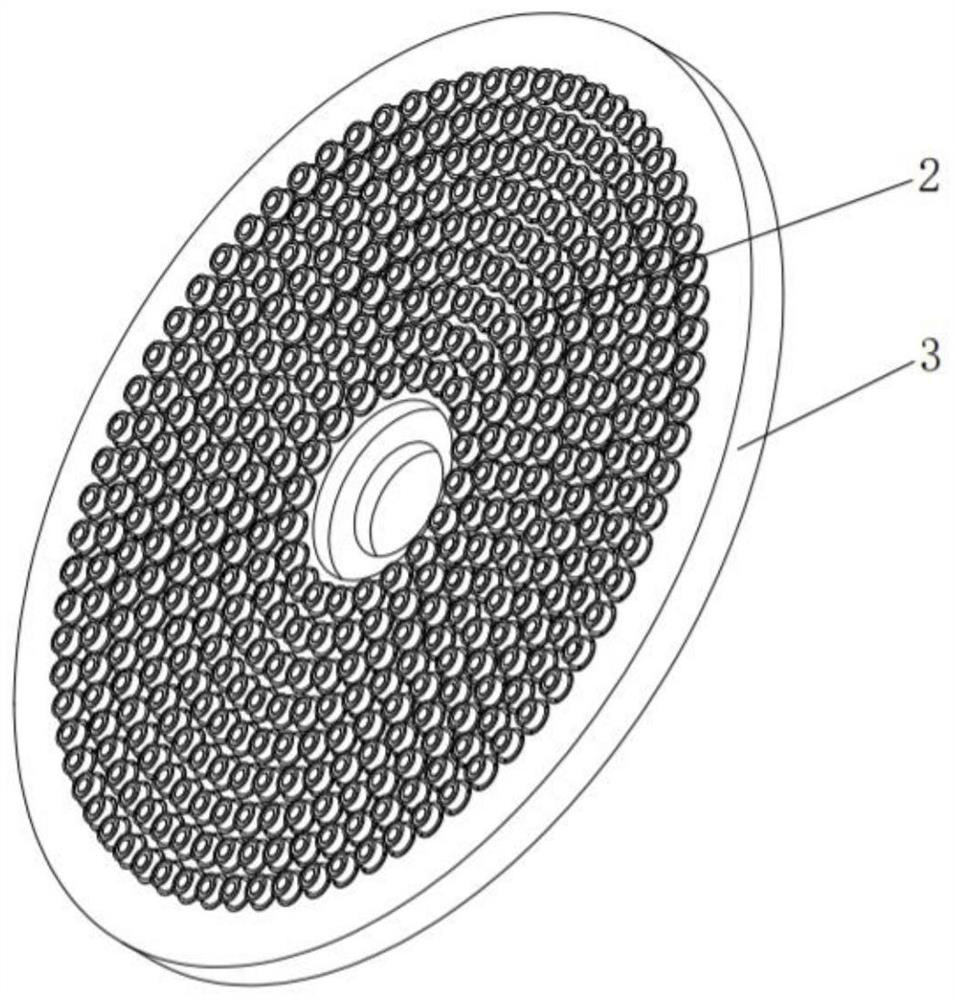

[0035] Such as figure 2 and Figure 5 As shown, a compound polishing method and device, firstly determine the initial polishing stiffness required by the polishing disc 1 according to the process parameters of the workpiece to be polished, and adjust the magnetic field of the ring electromagnet 2 through the shunt device 6 in the control box The strength makes the corresponding area of the polishing disc 1 reach the initial grinding stiffness, Figure 5 Center 1-1 is the corresponding initial rigidity area on the polishing disc 1. Then set the magnetic field intensity of equal gradient reduction in other areas of the annular electromagnet 2 of the circumferential array on the base 3, so that the corresponding areas of the grinding and polishing disc 1 present different stiffnesses, Figure 5Among them, 1-2 and 1-3 are the areas with different stiffnesses on the polishing plate 1, and the stiffness of the polishing plate 1 gradually decreases from the area 1-1 to the area ...

Embodiment 2

[0037] Such as figure 2 and Figure 6 As shown, a compound polishing method and device, compared with Embodiment 1, this embodiment makes four kinds of different magnetic field regions correspondingly distributed on the polishing disk 1 by adjusting the magnetic field strength of the ring electromagnet 2, and the polishing disk 1 Corresponding to four different rigidity areas 1-4, 1-5, 1-6, 1-7 respectively, 1-4 is the initial grinding rigidity area required by the grinding and polishing disc 1 determined according to the processed parts, 1-5, 1-6, 1-7 are the rigidity areas on the grinding and polishing disc 5 corresponding to the magnetic field with equal gradient reduction, then the rigidity of the grinding and polishing disc 1 from the area 1-4 to the area 1-5 to the area 1-6 to the area 1-7 slowing shrieking. Before work, the base 4 is fixed on the CNC machine tool, the workpiece 9 is fixed on the workpiece fixture 8, and the polishing spindle 7 is installed on the CNC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com