Intelligent automatic metallographic grinding and polishing machine

A grinding and polishing machine and automatic technology, which is applied in the direction of grinding machine tools, grinding machine parts, grinding/polishing equipment, etc., can solve the problem that abrasive materials cannot be fully programmed and fully controlled, and cannot meet the complex precision grinding of new process materials Polishing, unable to load pressure regulation and other problems, to achieve the effect of convenient grinding and polishing requirements, meeting grinding and polishing requirements, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

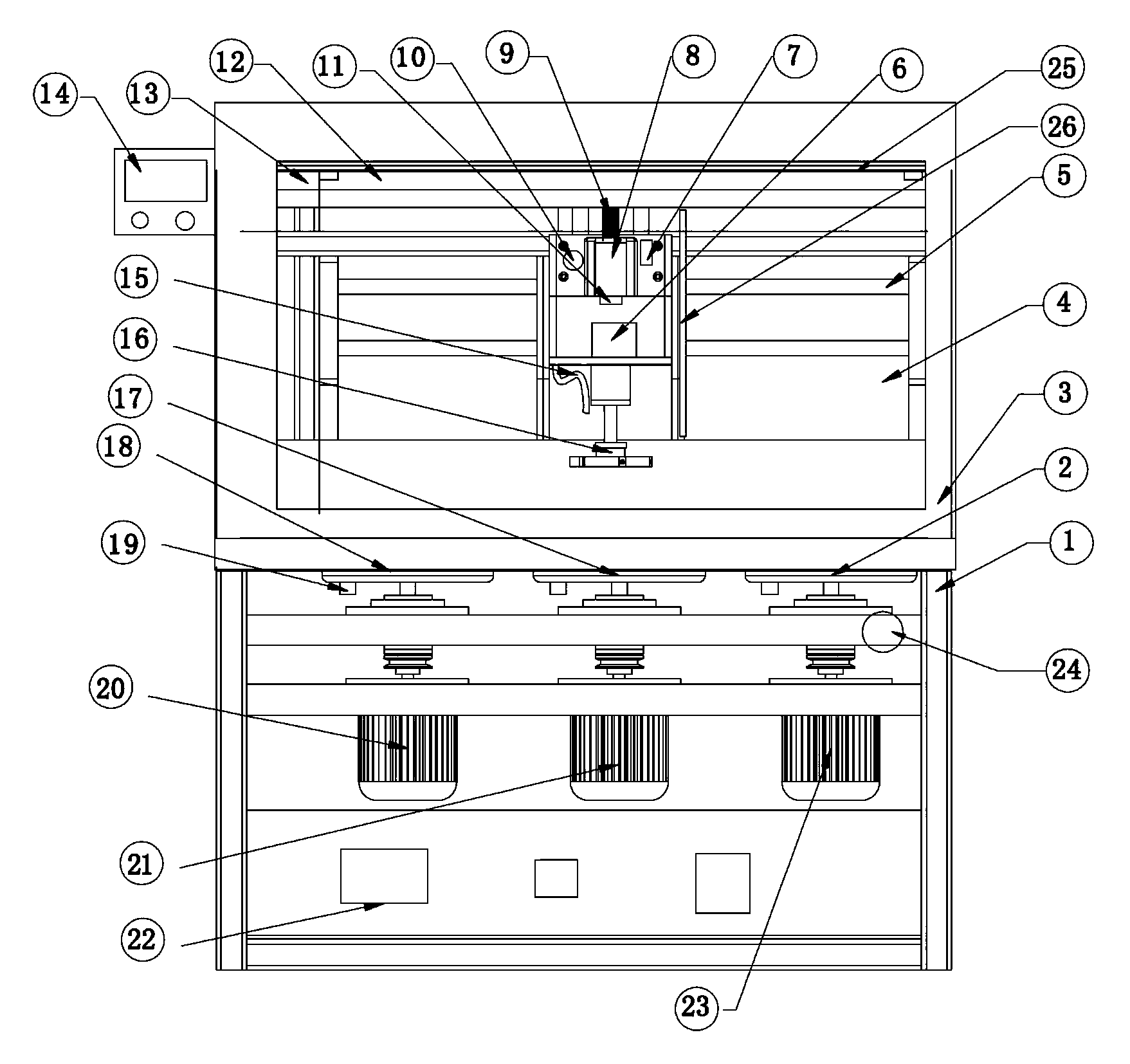

[0009] see figure 1 , the specific embodiment adopts the following technical solutions: it comprises a main frame 1, a polishing disc 2, an upper casing 3, a transparent window 4, a moving optical axis 5, a grinding head lifting motor 6, an abrasive box 7, a grinding head rotating motor 8, Grinding head lifting screw 9, feeding pump 10, force sensor 11, left and right driving screw 12, left and right driving motor 13, touch screen 14, cooling pipe 15, sample holding disc 16, fine grinding disc 17, coarse grinding disc 18, drain pipe 19. Coarse grinding motor 20, fine grinding motor 21, PLC controller 22, polishing motor 23, cooling water valve 24, LED lighting lamp 25 and grinding head group 26; A transparent window 4 is installed on the front of the shell 3, a touch screen 14 is connected to the upper left corner of the upper cover 3, an LED lighting 25 is installed on the inner top of the upper cover 3, and a moving optical axis 5 is installed on the rear side of the main fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com