Coated abrasive tool based on fiber substrate sand rope, polishing and grinding wheel and manufacturing method thereof

A technology for coating abrasives and polishing wheels, applied in grinding/polishing equipment, wheels with flexible working parts, abrasives, etc., can solve waste, shorten the service life of polishing wheels, and affect the use effect of polishing wheels, etc. problems, to achieve the effect of reducing the cost of use and improving the grinding and polishing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

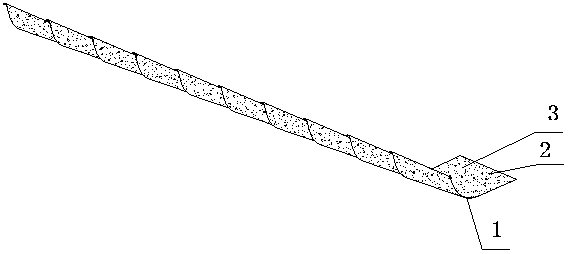

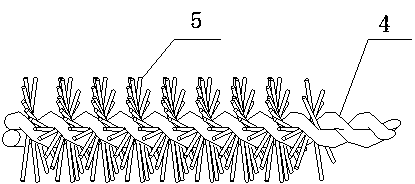

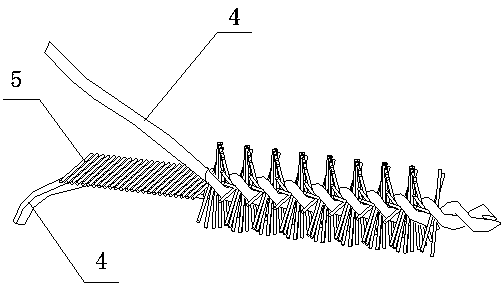

[0037] 1. Production of sand rope:

[0038] 1.2 Mortar impregnation: the cured emery cloth is cut and then twisted into a rope and impregnated with prepared mortar. (The mortar is: modified liquid phenolic resin solution 35%, abrasive: 45%, filler: 15%, thinner: 5%, mortar solid content: 75-77%, slurry amount: per gram of sisal 0.7-0.8g on fiber rope); then bake at 80±2°C for 60min.

[0039] 1.3 Roll a circle of primer on the dipped sisal fiber rope (the primer is : modified liquid phenolic resin solution 65%, filler: 35%, glue solid content: 75-77%, glue The amount is: 0.7-0.8g per gram of sisal fiber rope); after rolling the primer, use the method of gravity sand planting to roll and plant the sand on the sisal fiber rope (the sisal fiber rope after the primer is in the sand flow Roll through the middle until the sisal fiber rope is evenly planted with sand on all sides, the amount of sand is controlled at: 3-4g per gram of sisal fiber rope); then bake at 80±2°C for 60mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com