Full-automation rhinestone grinding and polishing machine

A fully automatic, grinding and polishing machine technology, used in grinding/polishing equipment, grinding machines, machine tools suitable for grinding workpiece edges, etc. effect, improve the quality of rhinestones, and expand the effect of grinding and polishing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

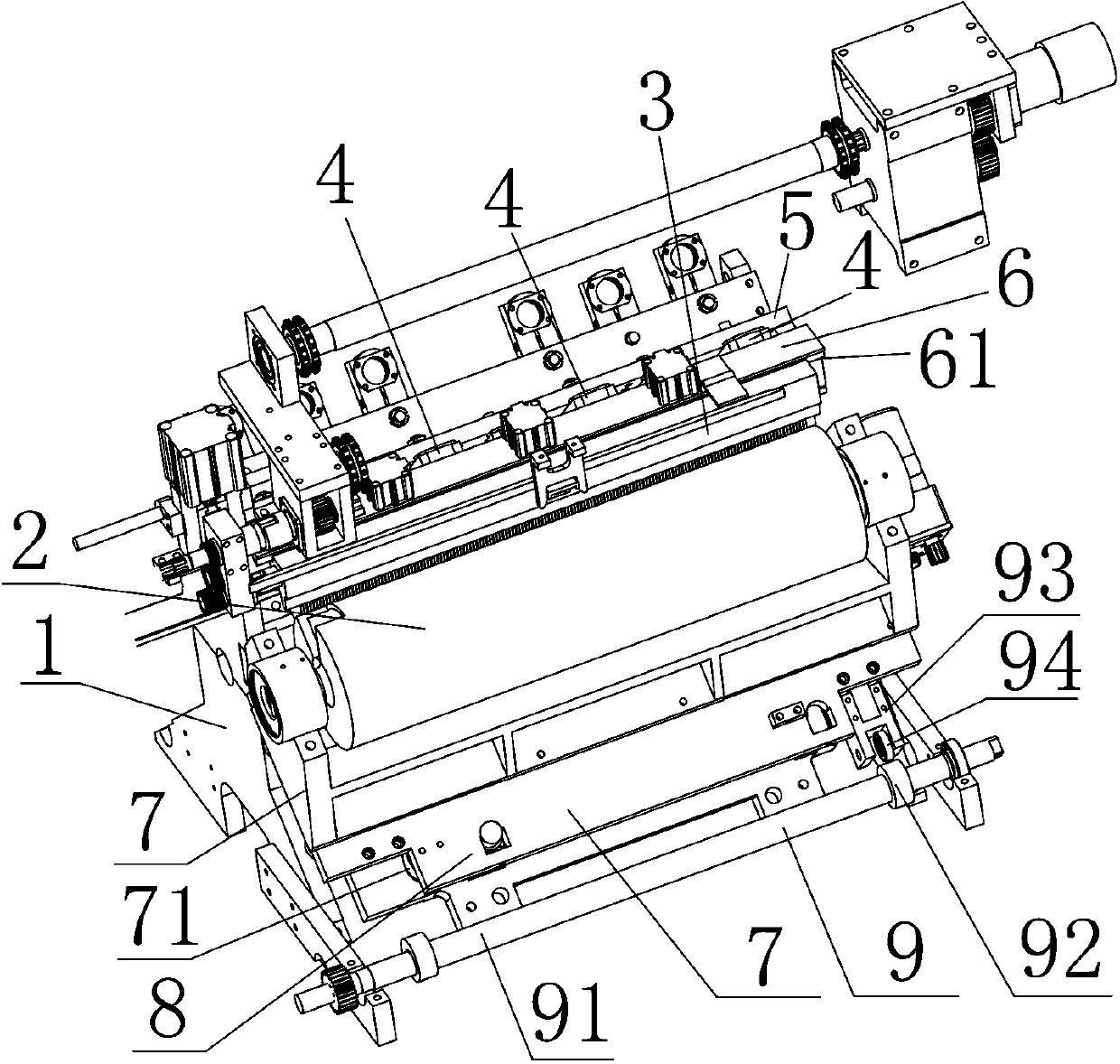

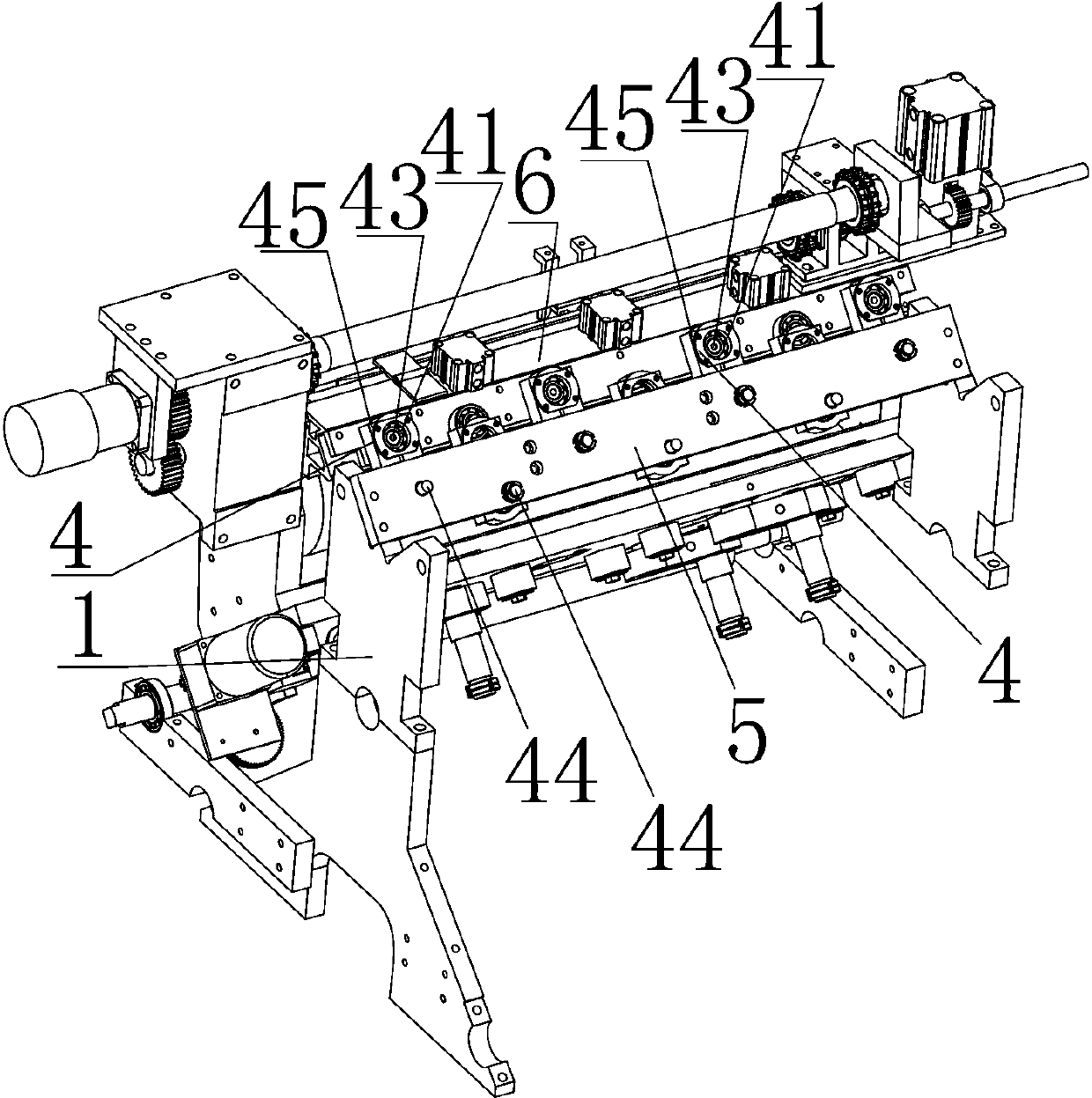

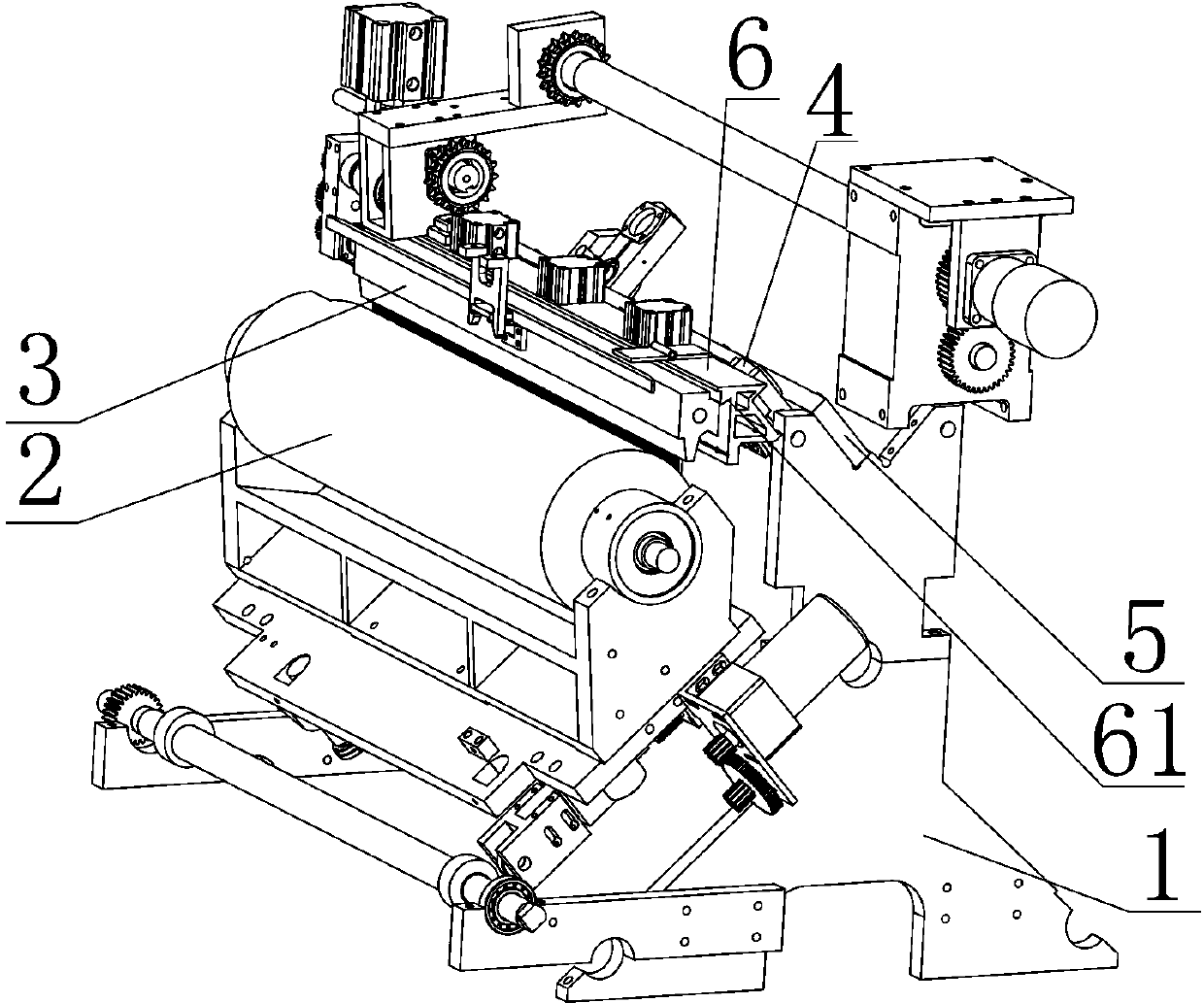

[0024] Such as figure 1 , figure 2 , image 3 , Figure 6 As shown, the embodiment of the automatic rhinestone grinding and polishing machine of the present invention includes a frame 1, a grinding and polishing wheel 2 and a fixture 3, the grinding and polishing wheel 2 and the fixture 3 are all arranged on the frame 1, and the rhinestone is positioned at the fixture 3 station Among them, the grinding and polishing wheel 2 abuts and acts on the water drill, the grinding and polishing wheel 2 and the clamp 3 relatively swing, and the relative swing track a between the grinding and polishing wheel 2 and the clamp 3 is arc-shaped. In this embodiment The two are in a relative pendulum motion, which can be that the grinding and polishing wheel 2 is stationary and the fixture 3 is pendulum relative to the grinding and polishing wheel 2, or that the fixture 3 is stationary and the grinding and polishing wheel 2 is pendulum relative to the fixture 3, or that the grinding and polis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com