Automatic pot grinding machine

An automatic and grinding technology, applied in the direction of grinding machine parts, grinding machines, grinding/polishing equipment, etc., can solve the problems of inability to realize automatic, low work efficiency, and difficulty in normal work, and achieve labor cost reduction and production. The effect of cost reduction and stable improvement of grinding and polishing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

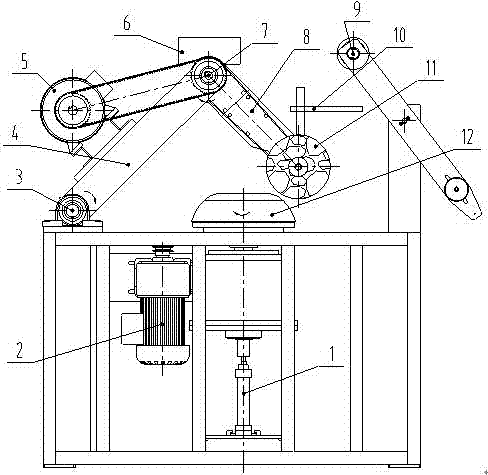

[0027] Such as figure 1 As shown, the present invention is divided into four parts, a clamping system, a repair system, a signal acquisition system and a flexible force application system.

[0028] The clamping system consists of two parts, including a rotary table, on which there is an external grinding fixed plate. When an external grinding pot is needed, it is buckled on the external grinding fixed plate, and the electromagnet is sucked tightly to press the pot on the fixed plate. On the plate, when the internal grinding pot is needed, there are several limit pressure wheels on the side of the fixed cylinder of the rotary table. The electromagnet attracts the outer bottom of the pot to fix the pot on the cylinder. When the rotary table rotates, When the pot is vibrated by the force of grinding, the pressure wheel rotates with the pot to correct the position of the pot.

[0029] The present invention prevents the pan body from shifting during high-speed rotation, and can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com