Full-automatic polishing device and method

A fully automatic and equipment technology, applied in grinding/polishing equipment, grinding/polishing safety device, metal processing equipment, etc., can solve problems such as difficulty in further improvement, great physical and mental harm to operators, and inadequate grinding and polishing treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

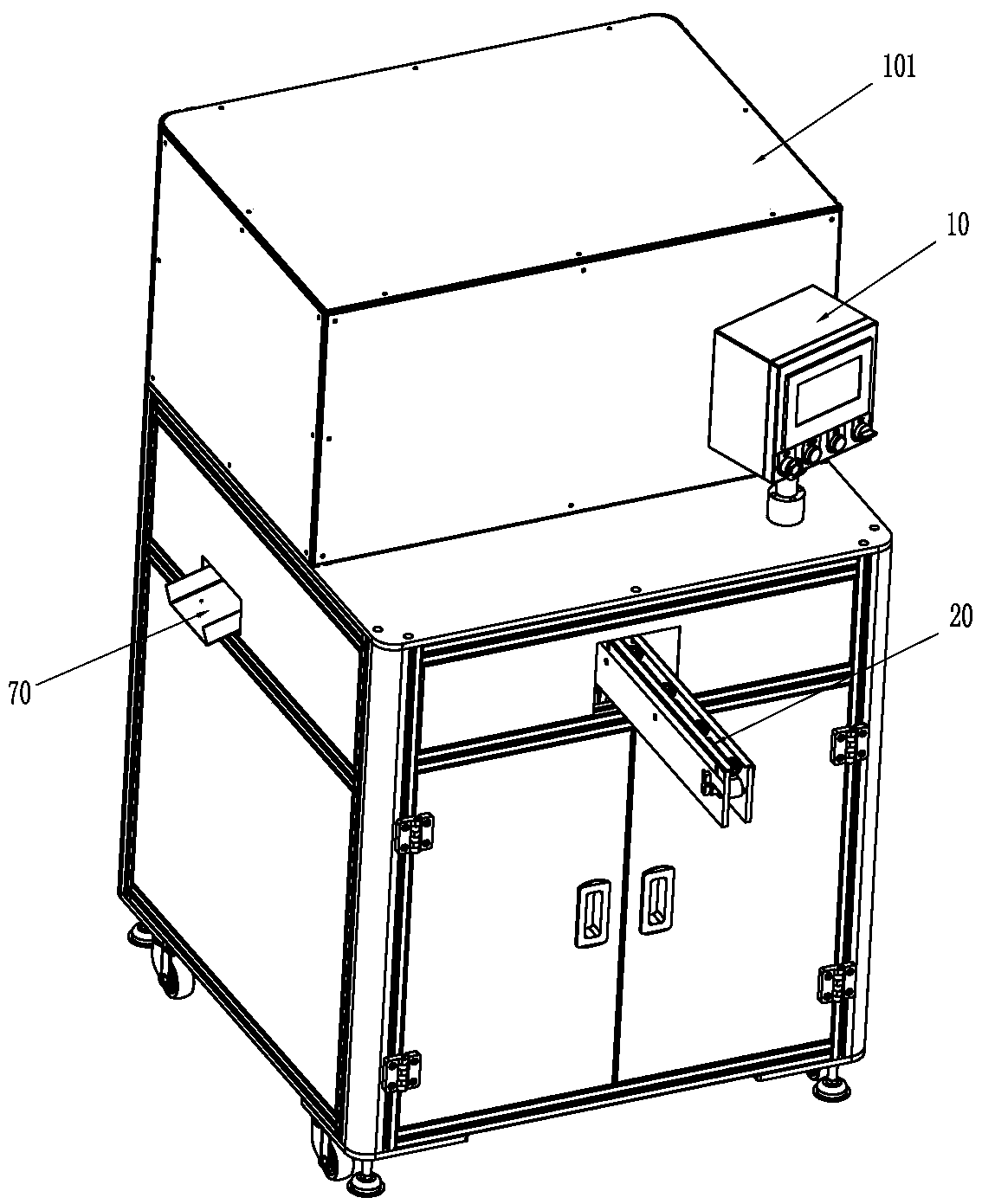

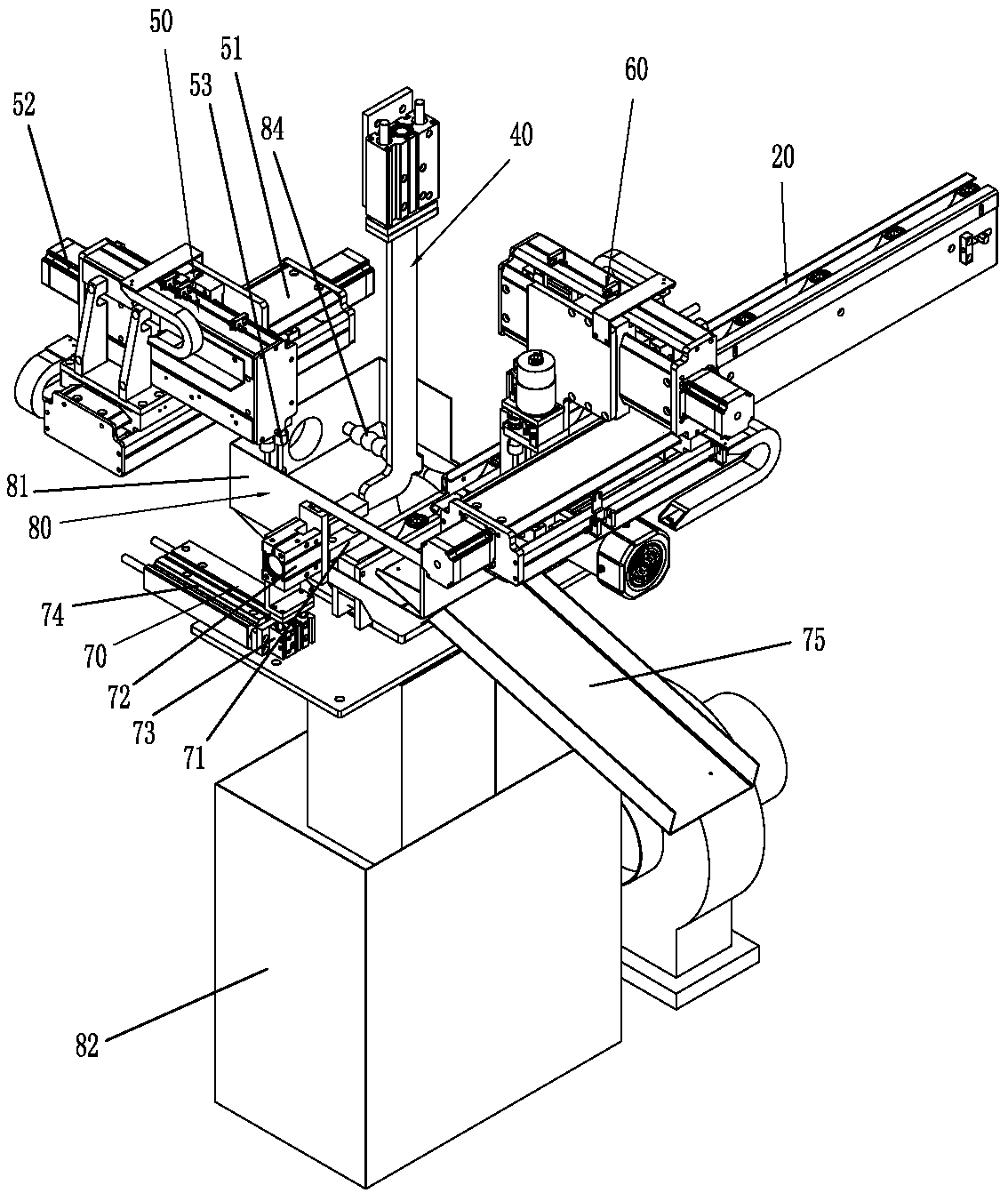

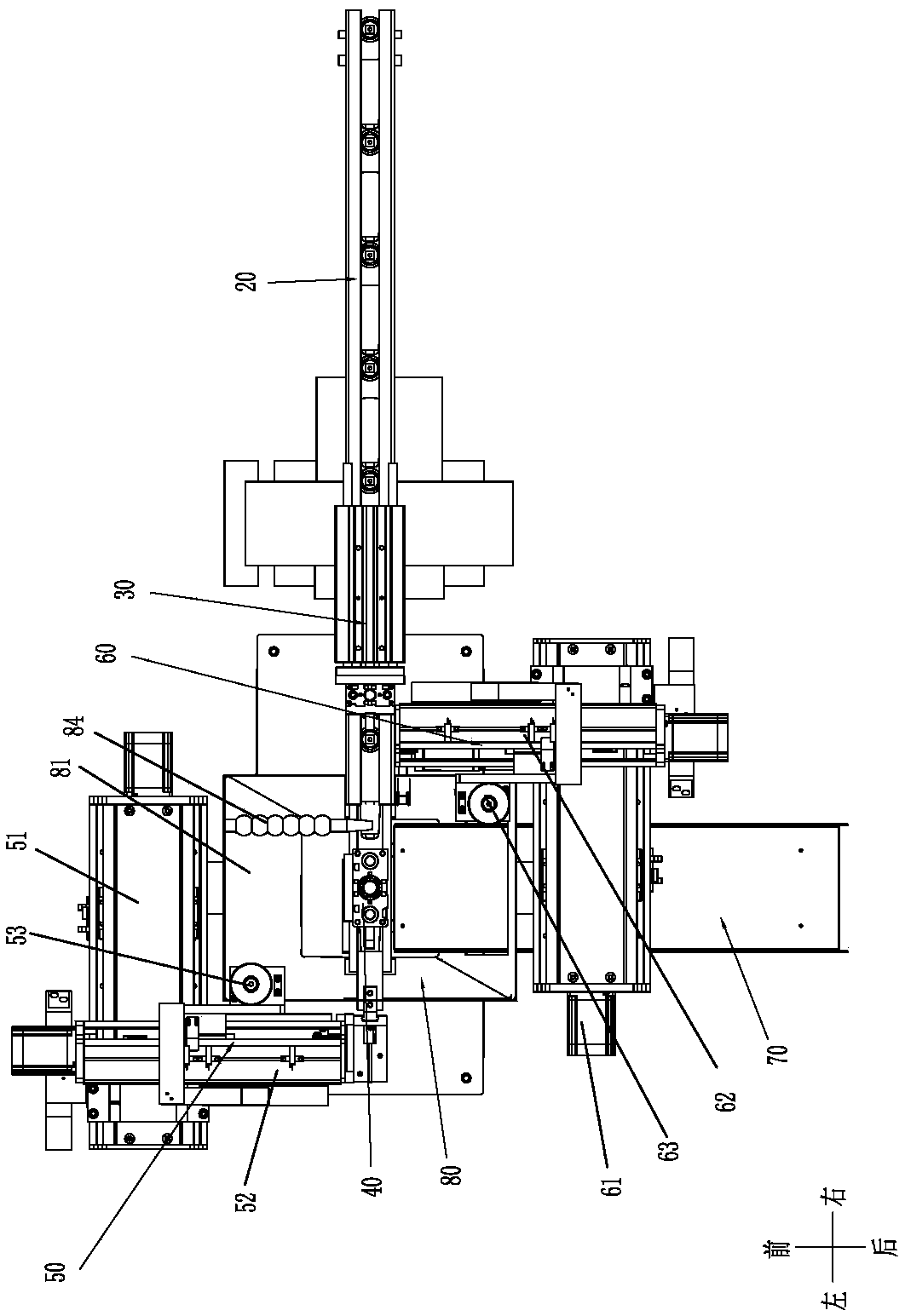

[0064] Please refer to Figure 1 to Figure 10 As shown, it shows the specific structure of the embodiment of the present invention, which is mainly applicable to, but not limited to, the grinding and polishing of hardware, and can be used for the grinding of mold lines, burrs, bumps, etc. Polishing; in this embodiment, the door handle product made of metal is taken as an example for illustration.

[0065] A full-automatic grinding and polishing equipment, including a main control unit 10, an automatic loading device 20, a workpiece clamping and positioning mechanism 40, a double-platform full-circle grinding and polishing device, and an automatic unloading device 70; wherein the main control unit 10 Respectively connected to the automatic feeding device 20, the workpiece clamping and positioning mechanism 40, the double-platform full-circle grinding and polishing device and the automatic unloading device 70; area; the feeding area and the unloading area are respectively conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com