Piece breaking device

A technology of splitting and lifting devices, which is applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of uneven splitting of cells, inadequate splitting, and high scrap rate, so as to avoid improper splitting and reduce waste rate, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

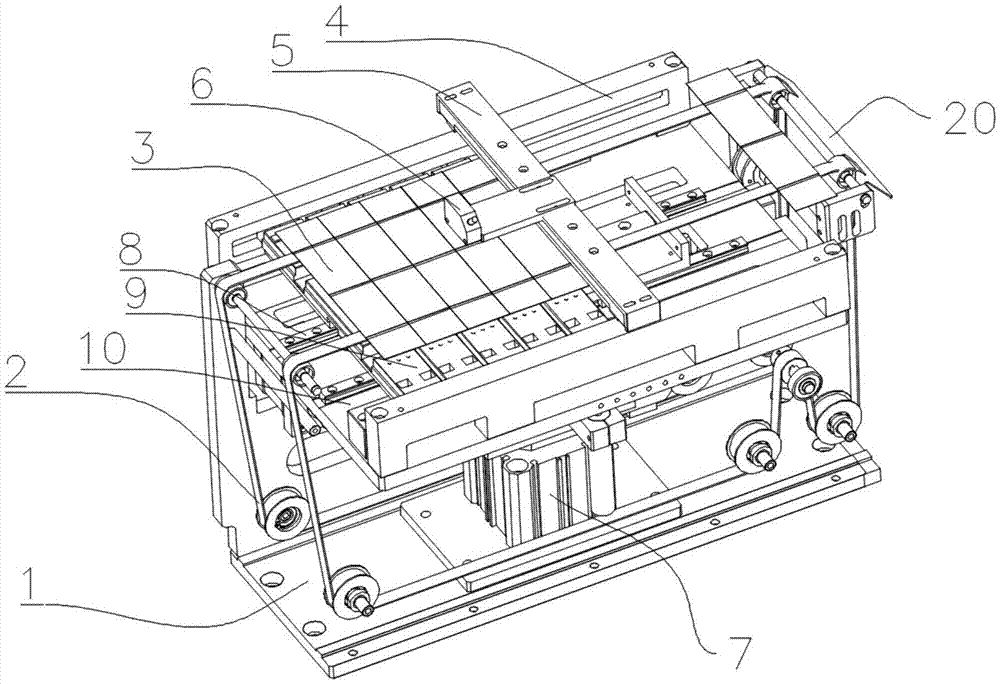

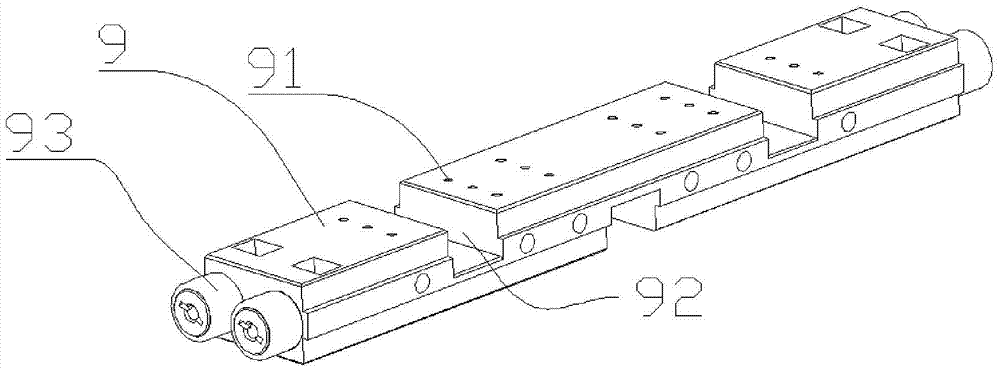

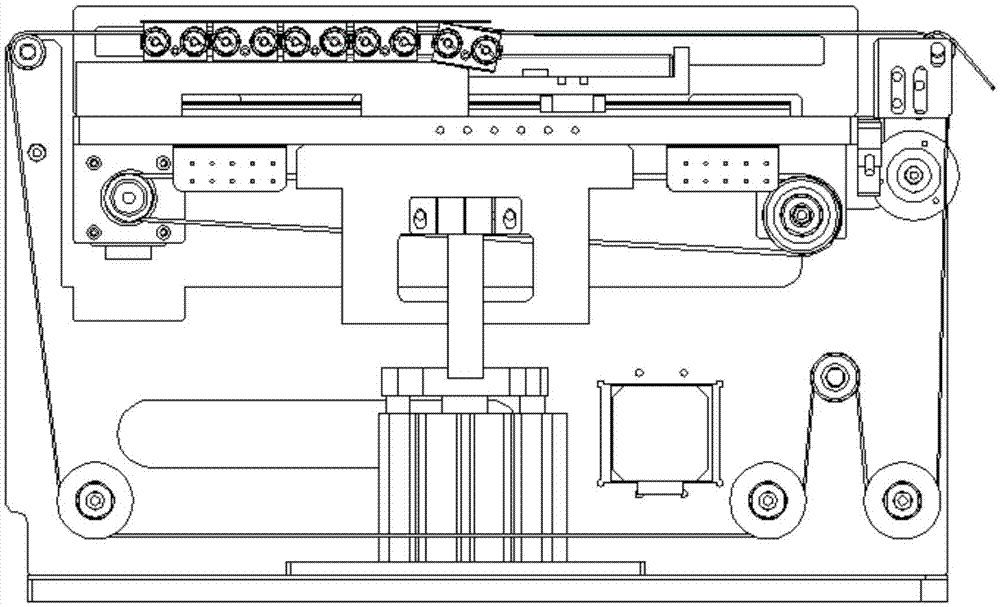

[0042] In order to achieve the purpose of the present invention, as figure 1 As shown, some embodiments of a chip breaking device in the present invention are: a chip breaking device, including a belt conveying device 2, used for conveying battery slice 3 products, and the belt conveying device 2 is connected to the support frame 1; The device 2 is composed of two symmetrically installed belts, the belts are driven by a motor, the lifting device 7 is connected with the support frame 1, and the cylinder is used to drive it to move up and down; The transmission suction cup 9 and the horizontal conveying device 8 matched by the special-shaped track 4 .

[0043] Adopting the above-mentioned technical scheme, the battery sheet products are conveyed in an assembly line through the belt conveying device, which greatly improves the conveying efficiency. When the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com