Storage battery grid conveyer line system and auxiliary feeding pushing device

A technology of pushing device and battery, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of insufficient sheet feeding, waste of materials, and increased cost, and achieve the effect of avoiding insufficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

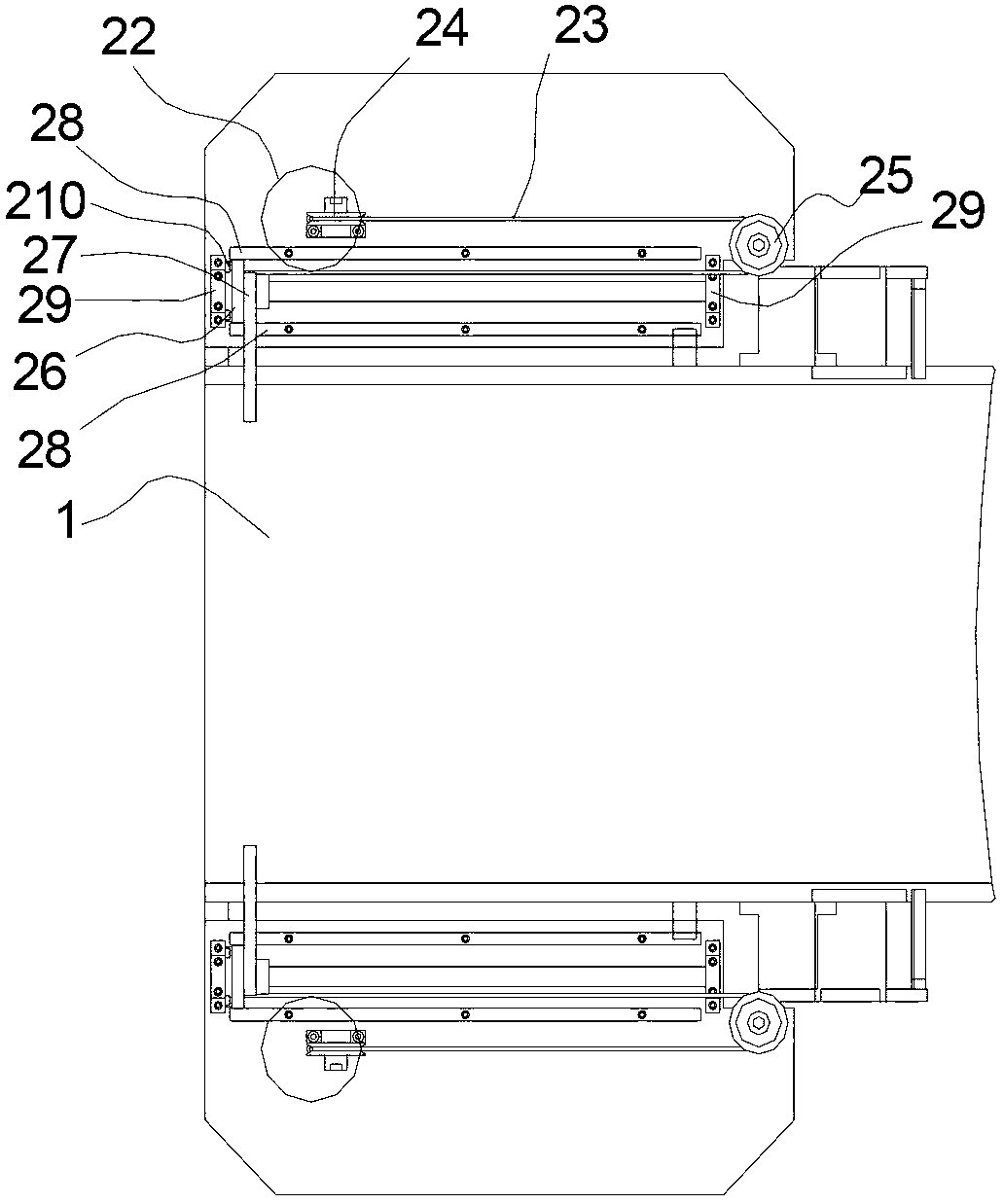

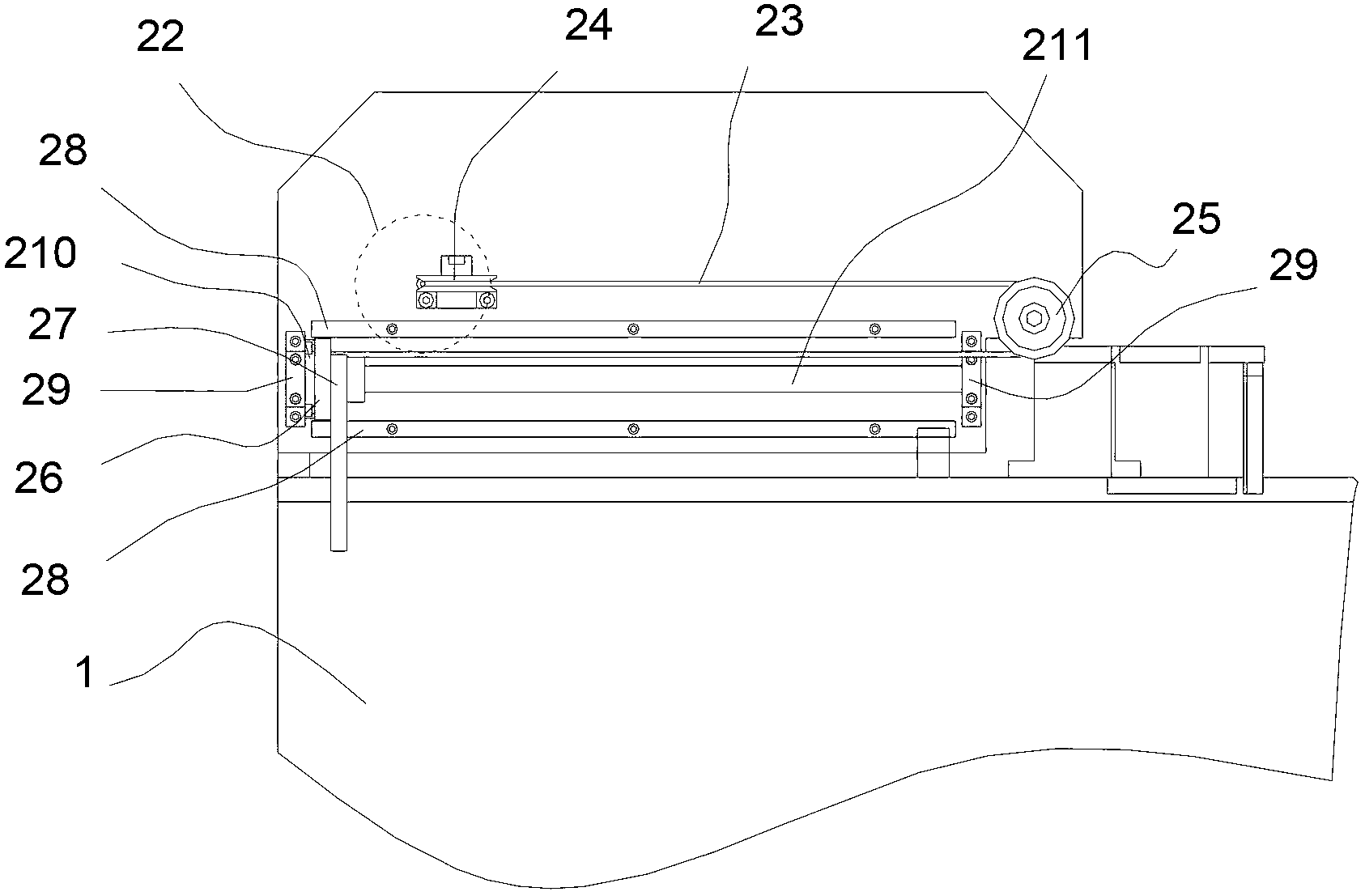

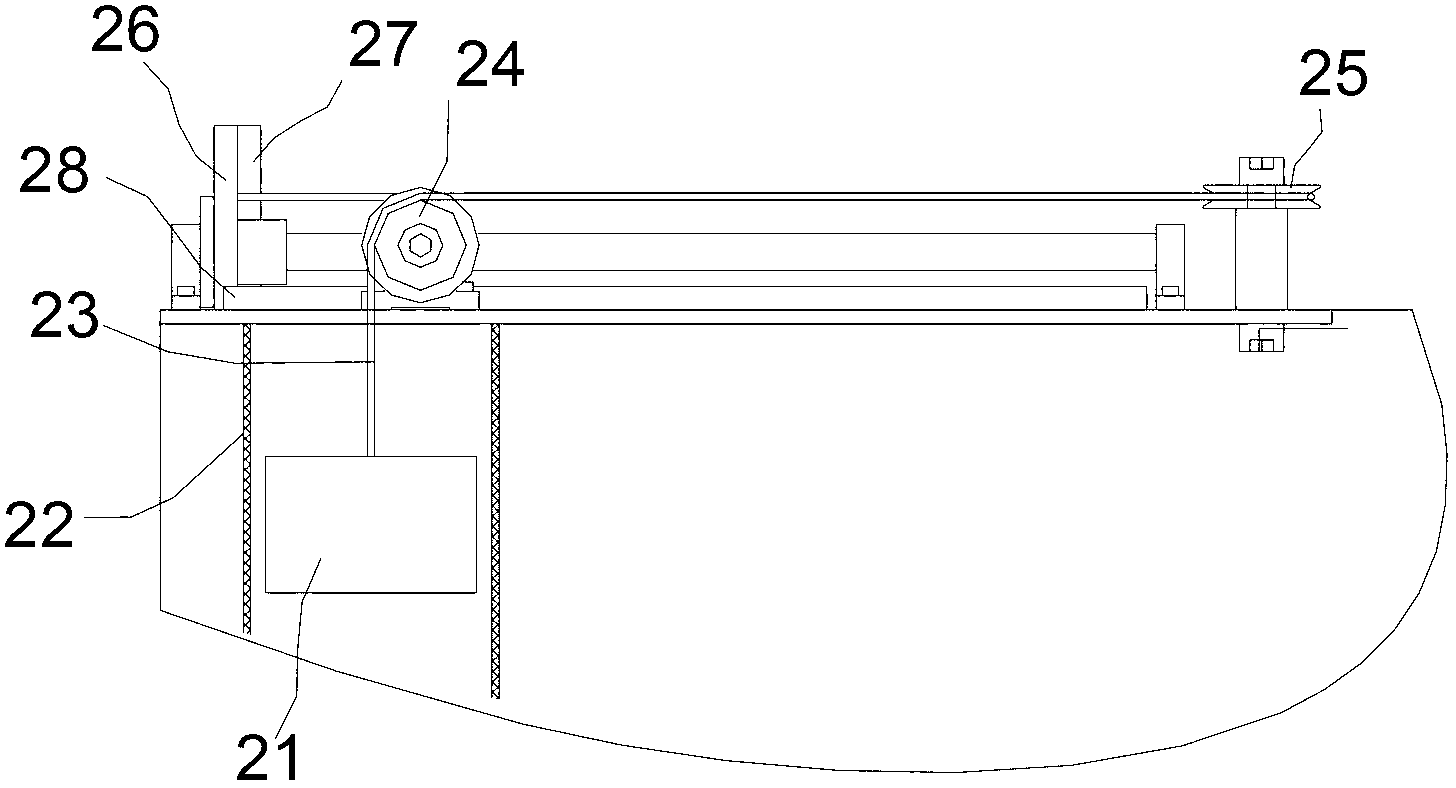

[0029] Please refer to Figure 1-3 , This embodiment includes a weight 21 , a first reversing member, a second reversing member, a guide shaft 211 , a fixing plate 26 and a pushing plate 27 .

[0030] This weight 21 provides the gravity of a free fall as a weight. Connect a steel wire rope 23 as a stay rope on the weight 21.

[0031] Further, in this embodiment, the first reversing member is a fixed first sheave 24 , the rotation center of the first sheave 24 is perpendicular to the direction of gravity, and the steel wire rope 23 is wound around the groove portion of the first sheave 24 .

[0032] The part of steel wire rope 23 that is arranged horizontally after being reversed by the first reversing member is reversed by the second reversing member, so that it is fixedly connected with the fixed plate 26 against the original horizontal direction. In this embodiment, the second reversing element is a fixed second sheave 25 , the rotation center of the second sheave 25 is pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com