Cement house construction system

A technology of cement and formwork, which is applied in the treatment of formwork/formwork/work frame, formwork/formwork components, formwork, etc. It can solve the problems of fast steam flow, steam waste, and inability to use steam effectively, and achieve steam curing Efficiency improvement, utilization rate improvement, efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, not to limit the present invention.

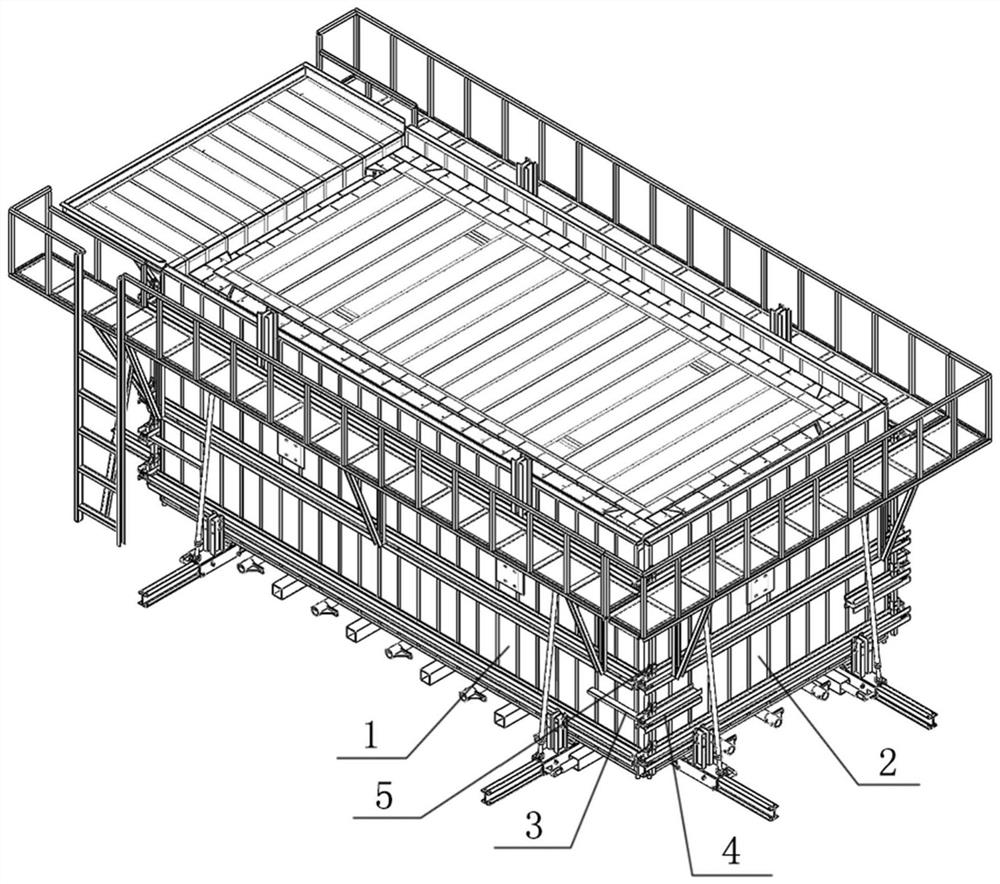

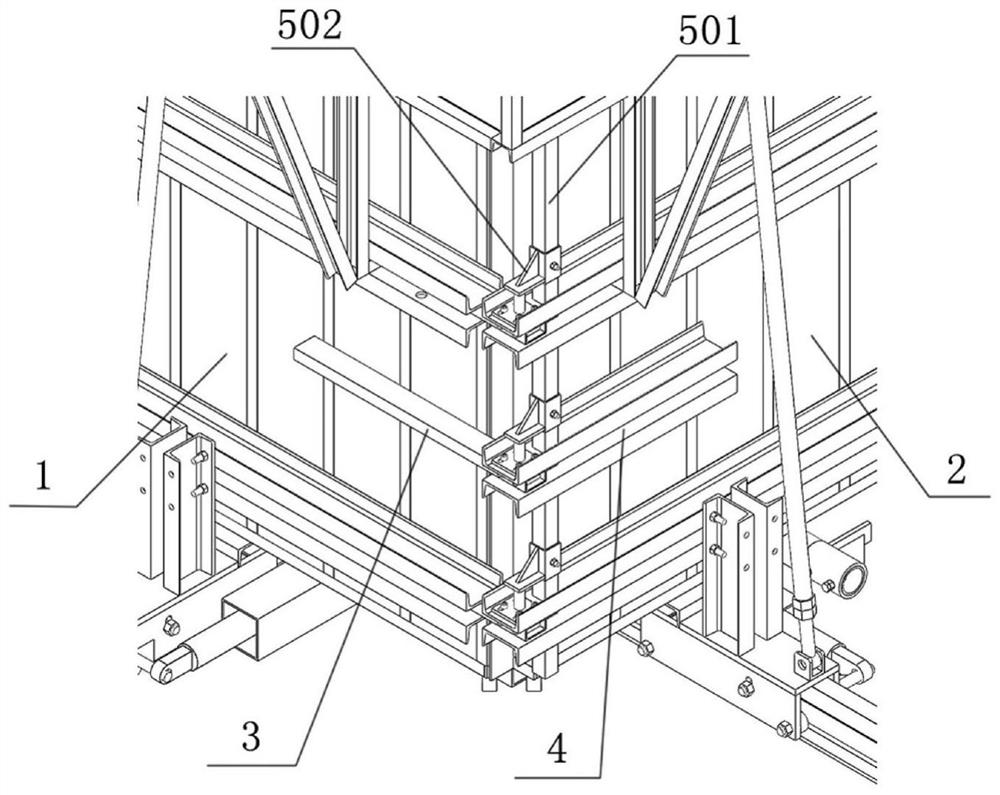

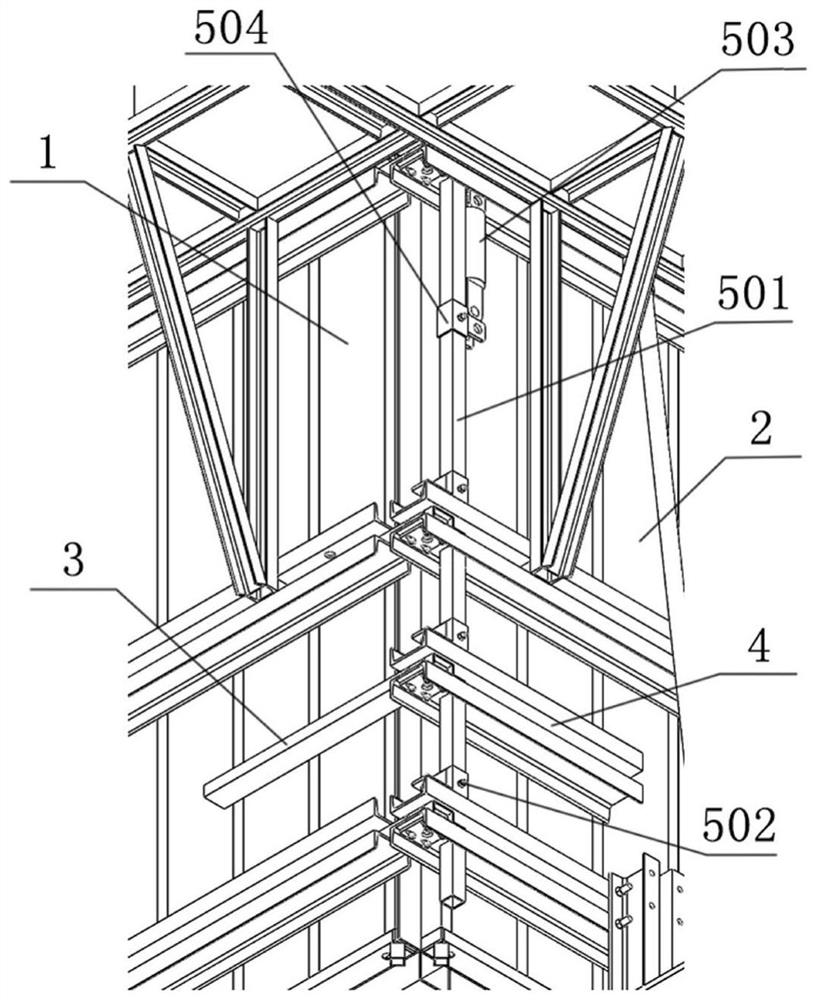

[0041] The invention discloses a cement room construction system, such as Figure 1-21As shown, it includes a pouring mold surrounded by vertical steam-cured templates, and a connecting frame is set up on the inner area of the pouring mold to form the inner template 18 and the outer template 1 of each steam-cured template. The lower part of the steam-cured template is clamped by the internal and external mold linkage clamping device, and the adjacent steam-cured formwork is locked by the adjacent edge alignment locking device, and the inner template 18 and the outer template 1 of each steam-cured template are respectively passed through the first mold release and clamping device. Cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com