Multifunctional grinding and polishing machine

A polishing machine, multi-functional technology, applied in the direction of grinding machine tools, grinding/polishing equipment, surface polishing machine tools, etc., can solve the problems of non-adjustable spindle angle, inability to process products with shape and structure, and inability to meet technical quality requirements, etc., to achieve The effect of improving the quality of grinding and polishing and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further explained below in conjunction with specific embodiments.

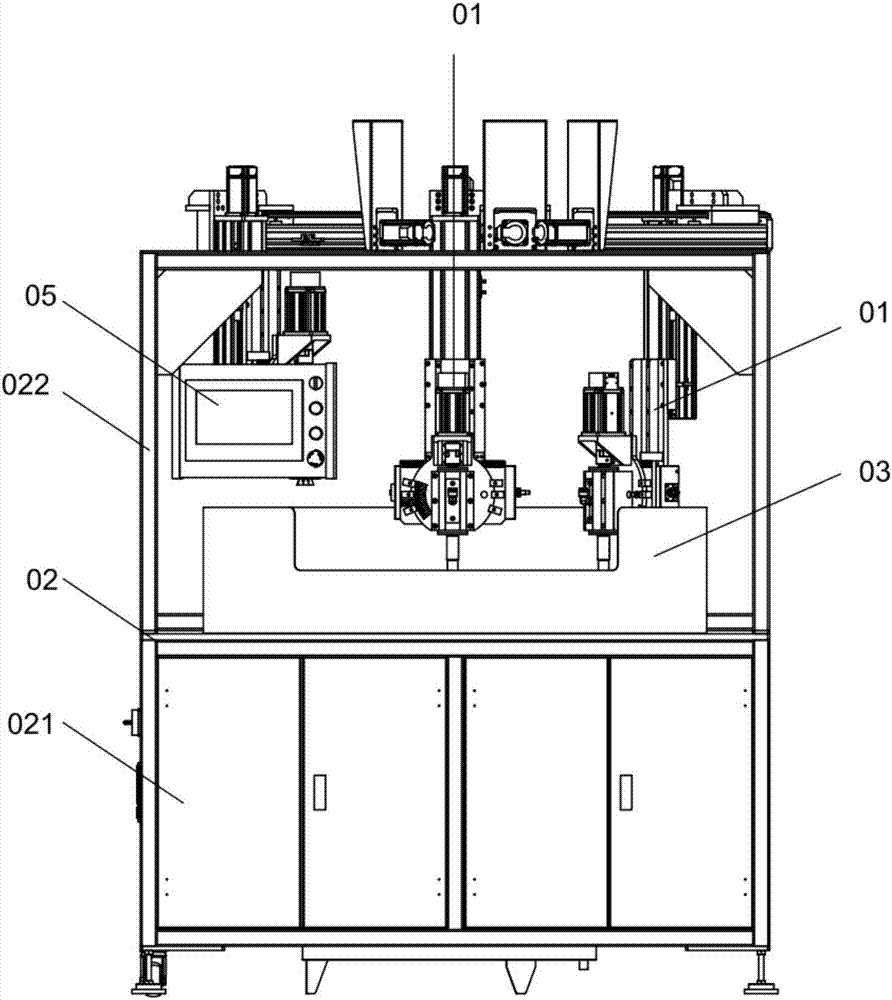

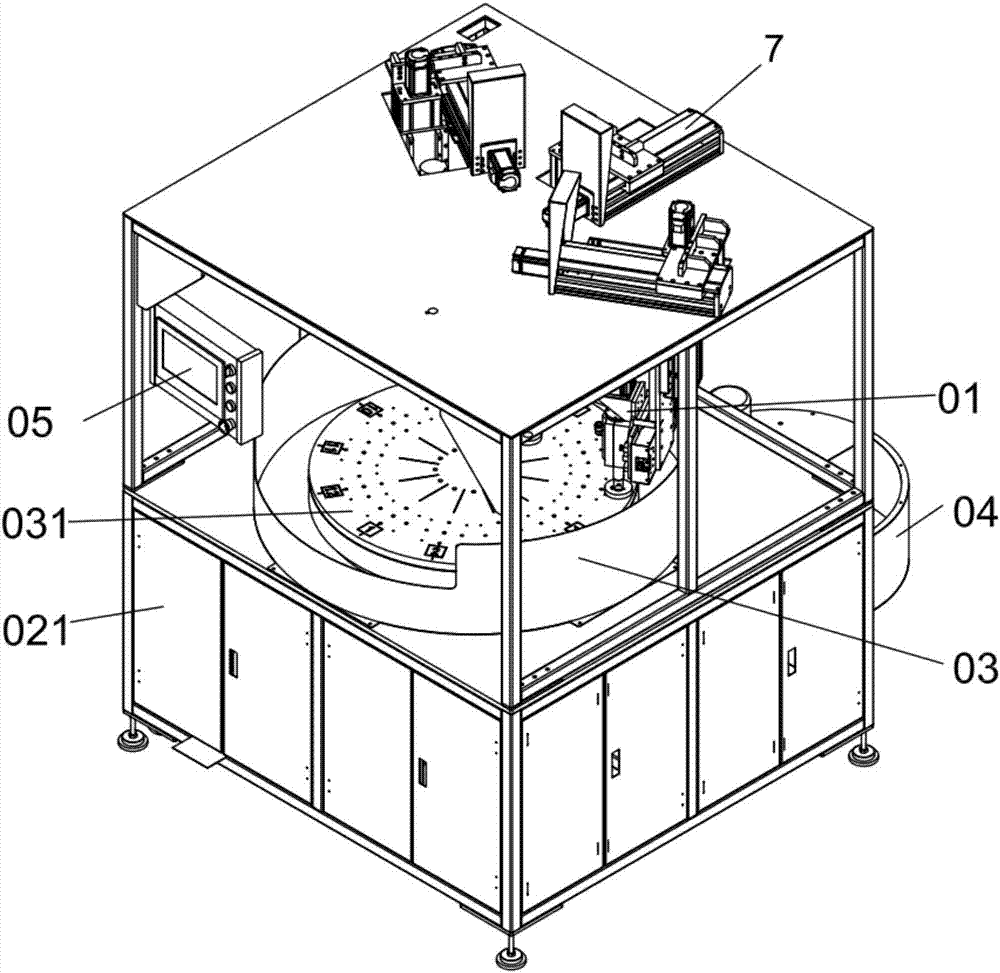

[0031] refer to figure 1 , figure 2 As shown, a multifunctional grinding, polishing and polishing machine includes a frame assembly 02, and the frame assembly 02 includes a bottom chassis 021 and a frame 022 on the chassis 021;

[0032] The turntable part 03 includes a turntable 031, and the turntable part 03 is arranged on the chassis 021;

[0033] The transmission mechanism 01 includes a main shaft mechanism 1 and X-axis 2, Y-axis 7 and Z-axis 8 which are arranged perpendicular to each other and can move independently or simultaneously. The main shaft mechanism 1 is arranged on the X-axis 2, and the transmission The mechanism 01 has multiple groups and is arranged on the frame 022, and is arranged correspondingly to the part surrounding the turntable 03;

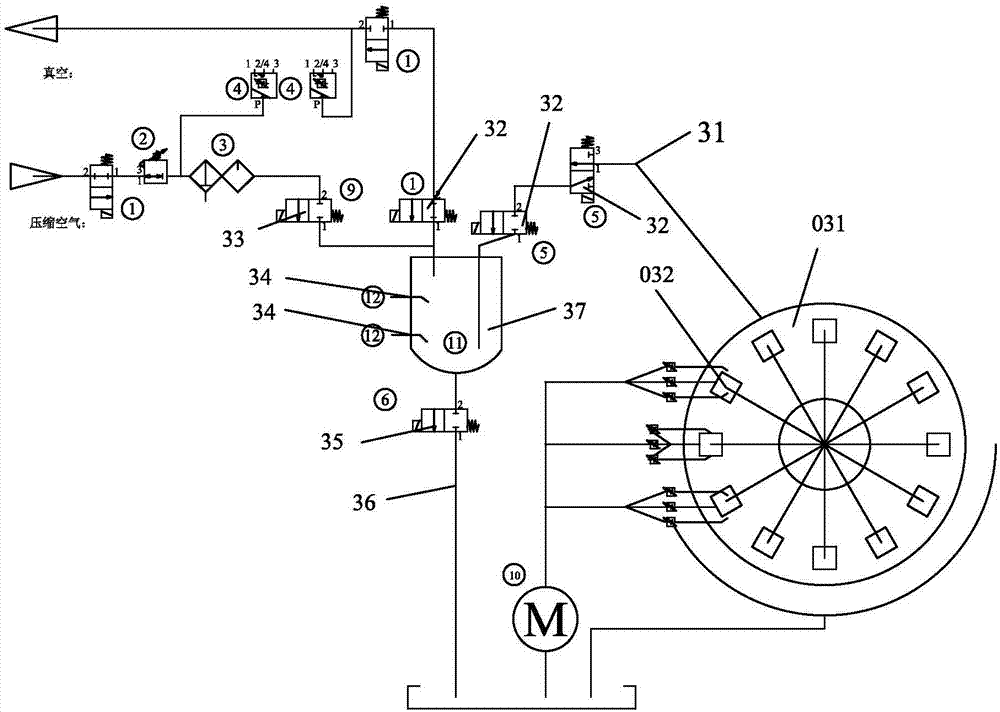

[0034] An air-liquid system 04, the air-liquid system 04 is arranged in the casing 021 and connected with the tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com