Longitudinal vibration type double-main-shaft wood polishing equipment

A dual-spindle, longitudinal vibration technology, used in grinding/polishing equipment, metal processing equipment, machine tools with surface polishing, etc., to improve the effect of grinding and polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

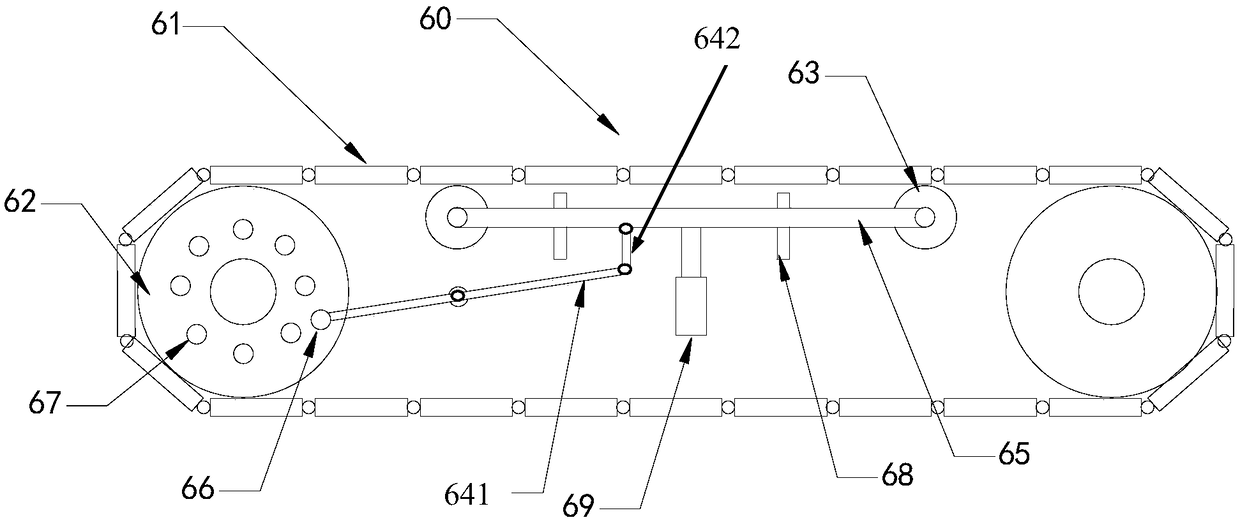

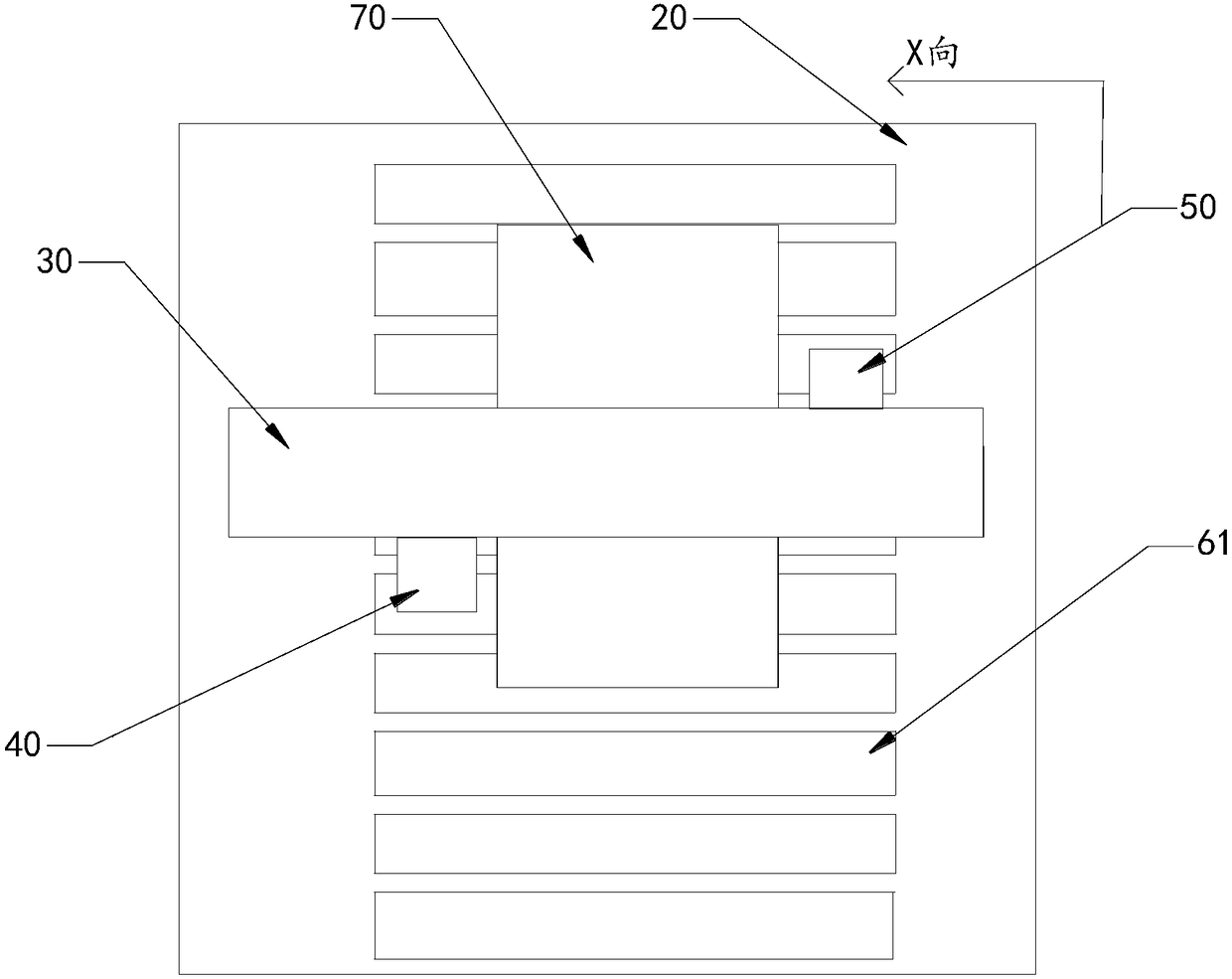

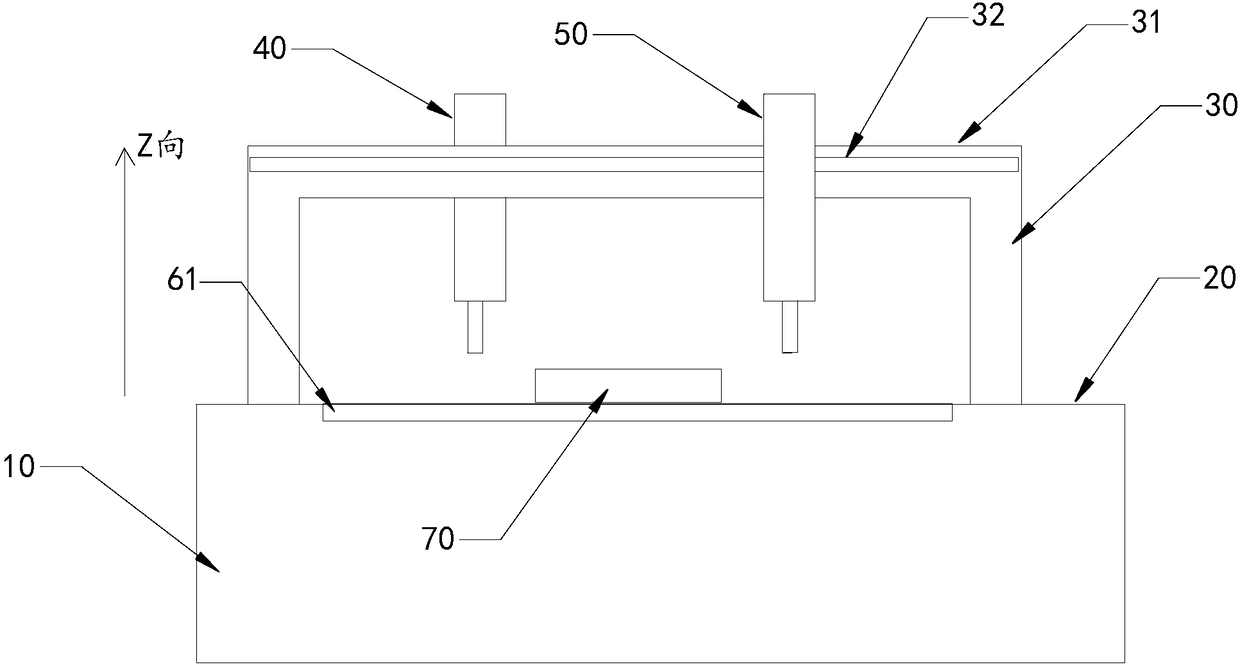

[0036] See attached Figure 1-3 , a longitudinal vibration double-spindle wood polishing equipment, including a base 10 , a workbench 20 , a gantry 30 , a first spindle 40 , a second spindle 50 and a longitudinal vibration transmission device 60 .

[0037] The workbench 20 is fixed on the base 10; the longitudinal vibration transmission device 60 is arranged on the workbench for transferring the workpiece 70; the gantry 30 is fixedly arranged on the workbench 20; the gantry 30 includes a beam and Two columns supporting the crossbeam, the first main shaft 40 and the second main shaft 50 are arranged on the crossbeam of the gantry 30, and the output ends of the first main shaft 40 and the second main shaft 50 are respectively provided with grinding wheels; on the crossbeam of the gantry 30 A slide rail and a lead screw are arranged along the longitudinal direction of the crossbeam. The first main shaft 40 and the second main shaft 50 are both slidably mounted on the slide rail, ...

Embodiment 2

[0043] On the basis of Embodiment 1, fixed parts are arranged at equal intervals on the conveying track, and the fixed parts are two blocks, one is fixedly arranged at one end of the conveying track, and the other is movably arranged at the same end as the fixed block. the corresponding other end of the block. The position of the movable stopper is provided with a corresponding concave chute, the movable stopper can slide on the downward concave chute, and the movable stopper is fixed at a position slightly wider than the width of the workpiece according to the width of the workpiece. It is convenient for the workpiece to move up and down under the action of the cam mechanism, and at the same time prevent the workpiece from sliding on the conveyor belt.

Embodiment 3

[0045] The longitudinal vibration double-spindle wood polishing equipment also includes an air blowing device, through which wood chips on the surface of the workpiece are blown off in time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com