Grinding and polishing device

A technology of grinding and polishing, base, used in measuring devices, grinding/polishing equipment, grinding machines, etc., can solve problems such as poor grinding and polishing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

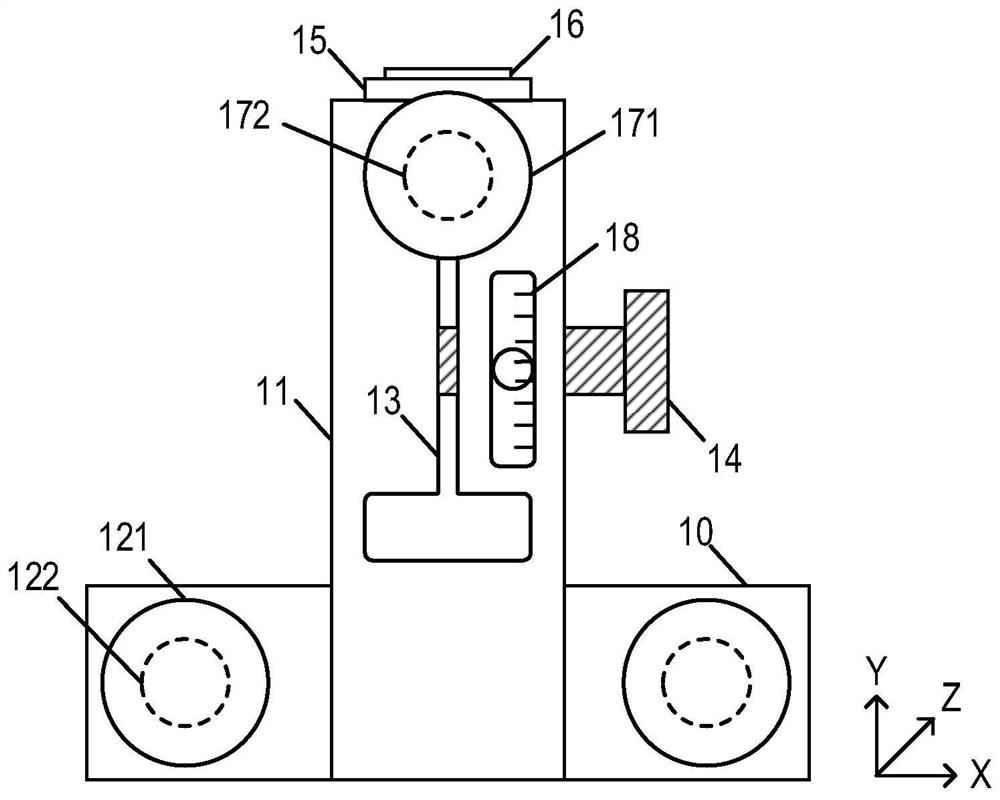

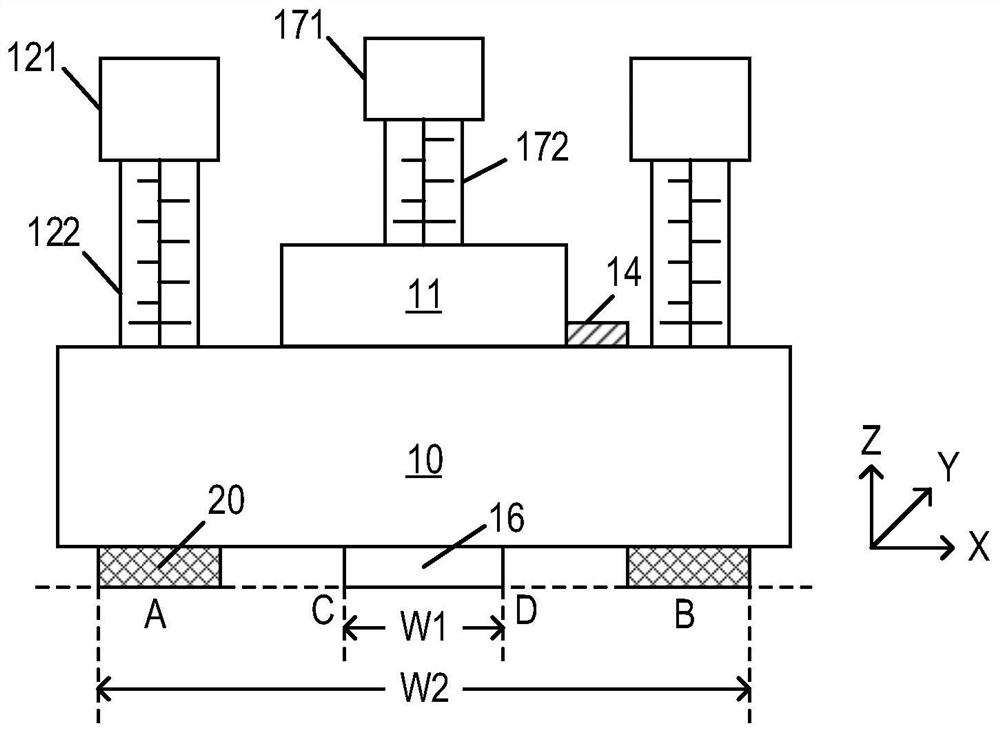

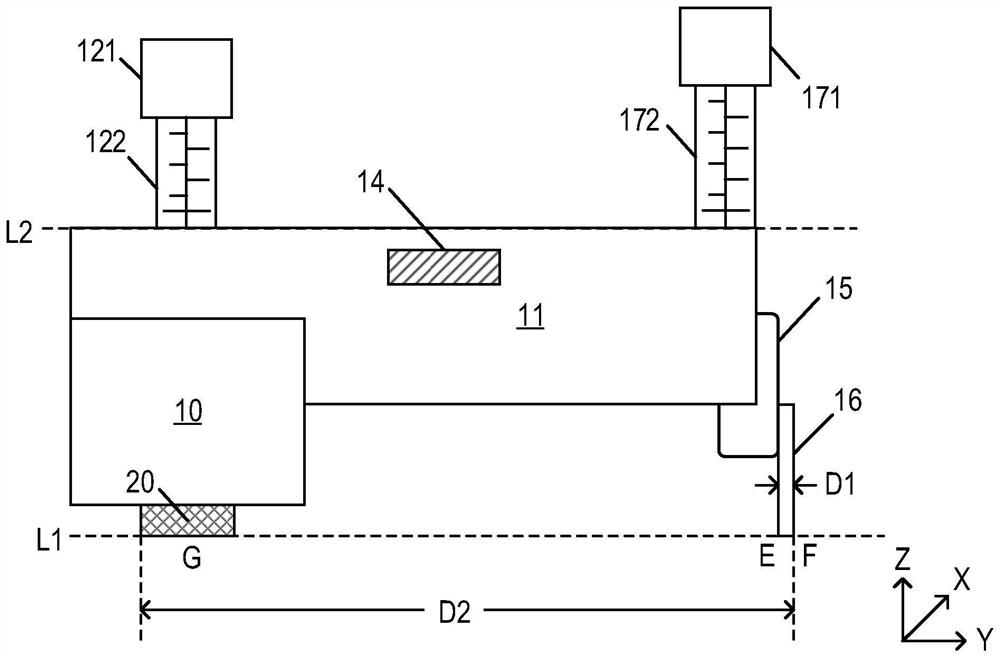

[0040] The specific implementation of the grinding and polishing device provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0041] In the process of grinding the sample with a grinding and polishing device with a T-shaped mold base, after the sample is fixed on the sample base of the grinding and polishing device by hot melt adhesive or other peelable glue, the sample base is inserted into the T-shaped mold base. In the card slot, the two pedestals at the bottom of the T-shaped mold base and the three fulcrums of the sample form a plane together, and the sample is manually polished or automatically polished by the grinding and polishing machine to prepare a sample with a flat surface. In order to carry out other treatments such as physical and chemical property analysis on the surface of the sample after grinding and polishing.

[0042] However, the current grinding and polishing device can only roughly adjust th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com