Winding tension reducing device and winding equipment

A technology of tension and mounting frame, which is applied in the direction of winding strips, transportation and packaging, thin material processing, etc., and can solve the problems of reducing winding tension and reducing pole piece winding tension.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

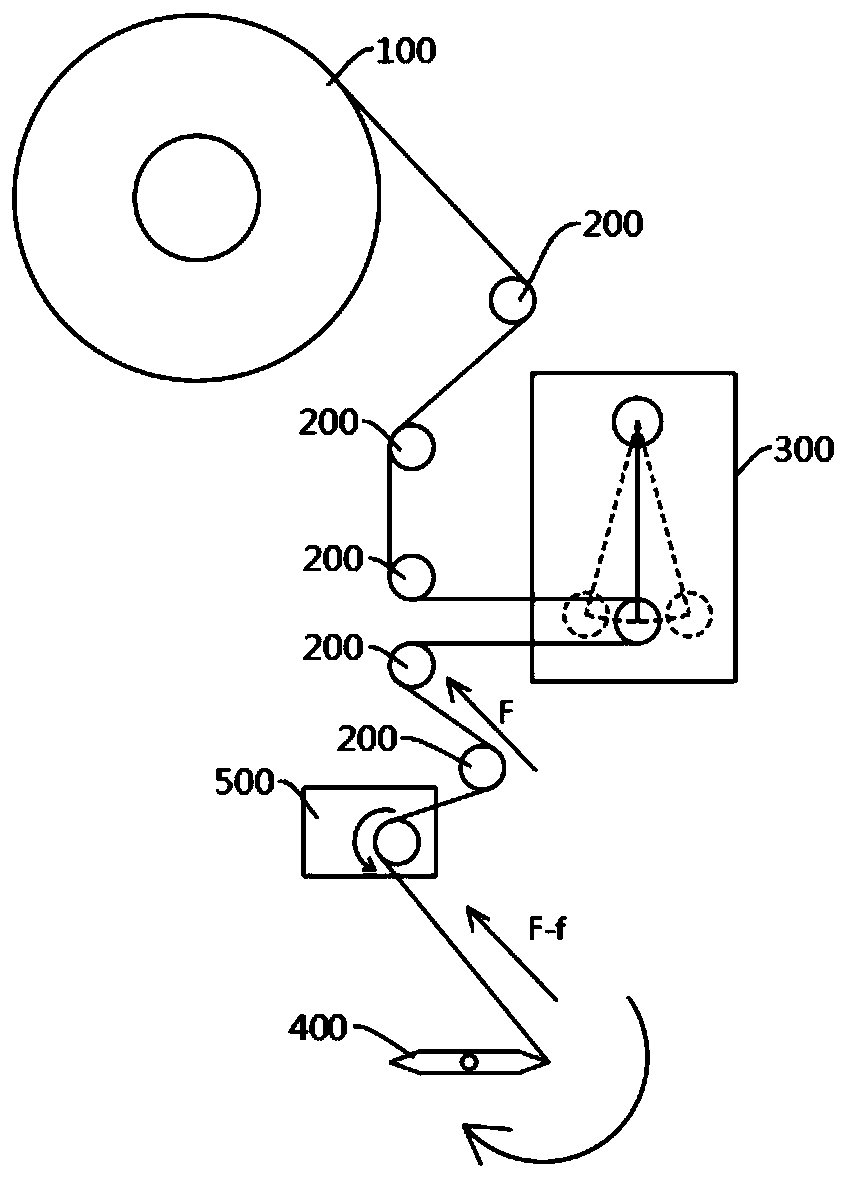

[0036] At present, there are many kinds of lithium-ion battery preparations, among which square winding lithium-ion batteries are one of the main preparation methods selected by lithium battery factories because of the efficiency advantage of winding preparation.

[0037] In the winding process of the pole piece of the square wound battery, it is necessary to make the coil material (that is, the pole piece strip) have a large tension to ensure the uniformity of the inside of the wound product, but after the winding is completed, the release link is static. If the tension If it is too large, it will cause severe deformation of the coiled product. Since the tension is too small during winding, it is easy to cause poor winding uniformity, and the tension after winding is too high, which will cause serious deformation of the wound product. Therefore, low-tension winding of square wound batteries has always been an urgent problem to be solved in the lithium battery industry.

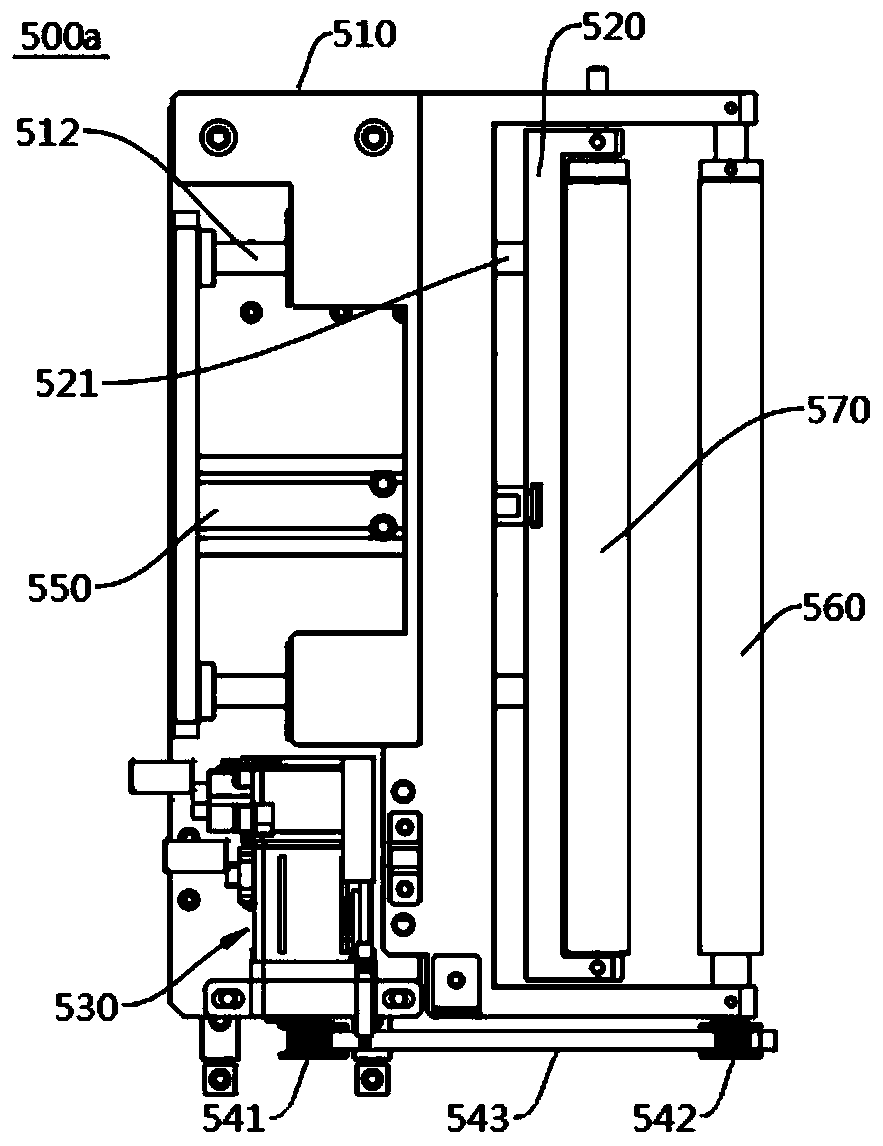

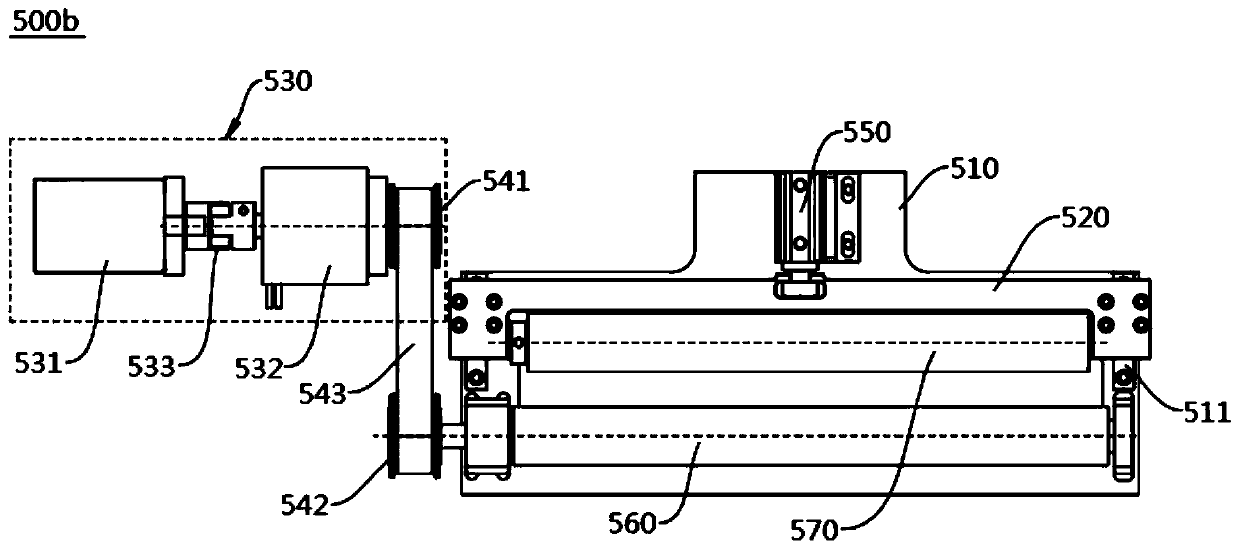

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com