Tobacco sheet for electronic cigarette and preparation method thereof

A technology for tobacco sheet and electronic cigarette, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of difficult operation, increased energy consumption, brittleness, etc., to reduce the horizontal drying stress, ensure leveling and cleanness, reduce Decapitation and fragmentation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

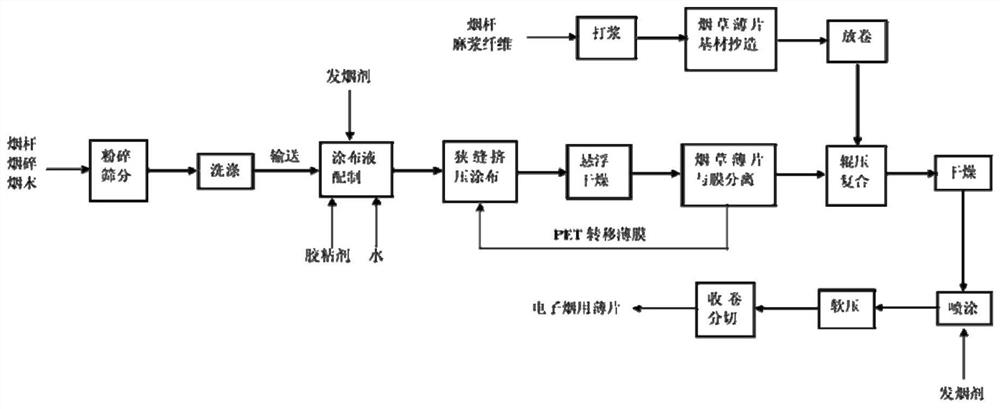

[0034] like figure 1 As shown, this embodiment provides a method for preparing tobacco sheets for electronic cigarettes, and the specific steps are as follows:

[0035] Step 1: Mix and beat the tobacco rod raw materials and wood pulp fibers according to the weight ratio of 1:1, and use the papermaking method to make 20g / m 2 Tobacco sheet substrate;

[0036] Step 2: Pulverize the crushed tobacco, tobacco stems, and tobacco powder with a pulverizer, and pass through a 150-mesh sieve to obtain tobacco powder. Take 30% of the weight of the tobacco powder as glycerin as the fuming agent, and take 1% of the weight of the tobacco powder to have a concentration of 2 % CMC solution as the adhesive, take water twice the weight of the smoke powder and mix it with the smoke powder, stir for 30 minutes, and prepare a high-concentration coating solution with a concentration of 26%.

[0037] Step 3: Prepare a smoking preparation with 1% by weight of tobacco powder (the mass ratio of tobacc...

Embodiment 2

[0043] like figure 1 As shown, this embodiment provides a method for preparing tobacco sheets for electronic cigarettes, and the specific steps are as follows:

[0044] Step 1: Mix and beat the tobacco rod raw material and hemp pulp fiber according to the weight ratio of 1:1, and use the papermaking method to make 20g / m 2 Tobacco sheet substrate;

[0045] Step 2: Pulverize the crushed tobacco, tobacco stems, and tobacco powder with a pulverizer, and pass through a 200-mesh sieve to obtain tobacco powder. Take a smoke-generating agent (the mass ratio of glycerin and propylene glycol is 2:1) by weight of the tobacco powder, and take 2% of the weight of the smoke powder and a 2% guar gum solution as an adhesive, mixed with water twice the weight of the smoke powder, and stirred for 30 minutes to prepare a high-concentration coating solution with a concentration of 24%;

[0046] Step 3: Prepare a smoking preparation with 1% of tobacco powder weight tobacco flavor (the mass ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com