Acid leaching device for fiber yarn rope

A technology of acid leaching and yarn rope, applied in the equipment field of acid leaching process, can solve the problems of low production efficiency, poor quality consistency of high silica glass fiber yarn rope, etc., to improve quality and production efficiency, improve acid The effect of non-uniform temperature rise and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 acid leaching device

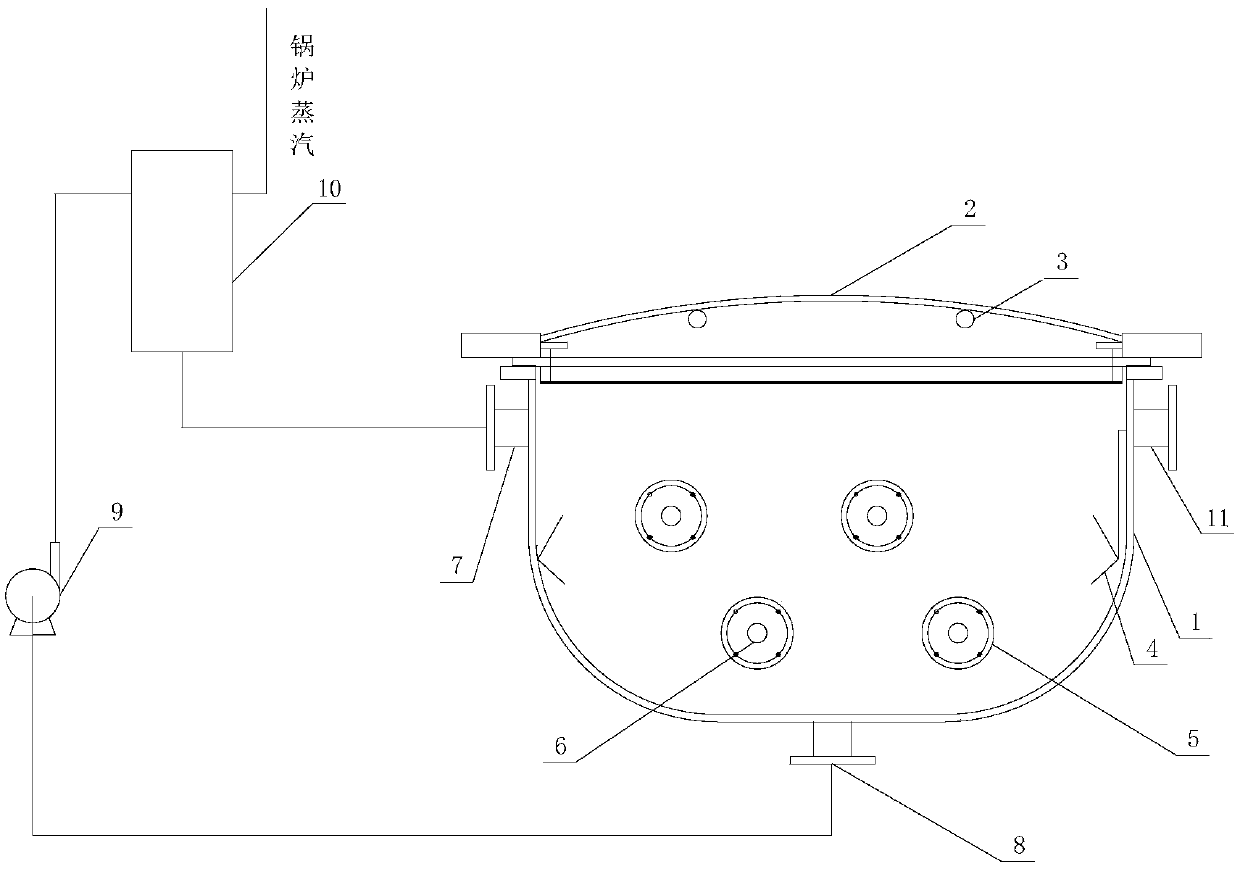

[0035] Such as figure 1A specific embodiment of the acid leaching device shown includes an acid leaching tank 1 and a heat exchange assembly 10, and the acid leaching tank 1 is provided with an acid inlet 7 and an acid outlet 8; wherein, the acid inlet 7 Set on the side wall near the top end of the acid leaching tank 1, the acid outlet 8 is set at the bottom of the acid leaching tank 1, and the opening of the acid leaching tank 1 is provided with a The acid leaching tank cover body 2; the heat exchange assembly 10 is arranged on the outside of the acid leaching tank 1, and is used for heating the acid liquid in the acid outlet 8 and then inputting it into the acid inlet 7 to complete the acid leaching The heating of the acid liquid, the heat exchange assembly 10 is provided with a medium flow channel for the circulation of the heating medium and an acid liquid flow channel for the circulation of the acid liquid, and the outlet of the...

Embodiment 2

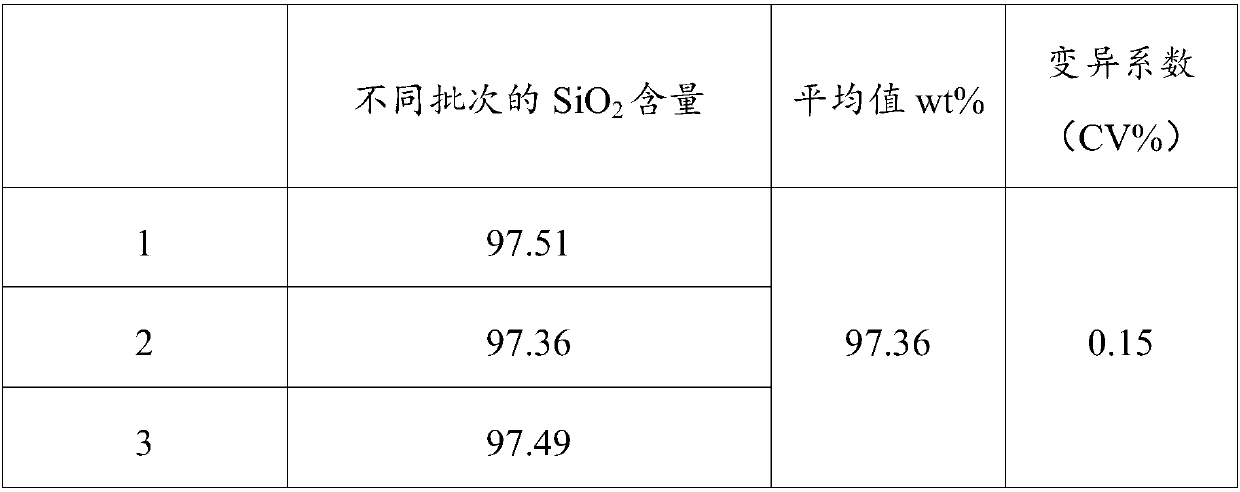

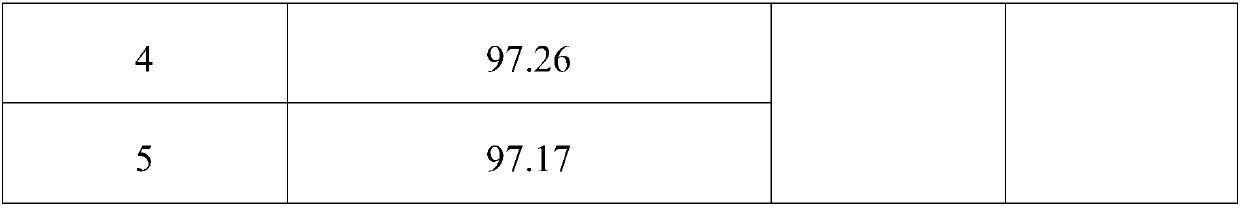

[0052] The production technology of embodiment 2 high silica glass fiber yarn rope

[0053] Acid leaching: wind the ternary sodium borosilicate glass fiber yarn rope (specification: BC8-220S120) on the acid-resistant creel with a winding ratio of 3.14. The radius of the circumscribed circle of the frame is 500cm, and the thickness of the yarn layer of the fiber yarn rope wound is 2.6cm, and then the creel is connected in the acid leaching tank by rotating the shaft; use the hydrochloric acid solution that the equivalent concentration is 3.1N / L as Acid solution, inject the hydrochloric acid solution into an acid-resistant heat exchanger and heat it to 50°C, then inject it into the acid leaching tank; then start the creel to rotate, control the creel rotation speed to 20rpm, and refill the acid solution in the acid leaching tank at the same time It is pumped into the heat exchanger for circulation heating until the temperature of the acid solution is 95°C, and then the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com