A kind of production equipment and preparation method of low linear density polyester fiber

A polyester fiber and production equipment technology, applied in the production equipment and preparation field of low linear density polyester fiber, can solve the problem of reducing the frictional resistance between the filament and the air, shortening the spinning process of the filament bundle, and poor cooling uniformity of the filament and other problems to achieve the effect of avoiding bad molding, reducing frictional resistance, and reducing winding tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

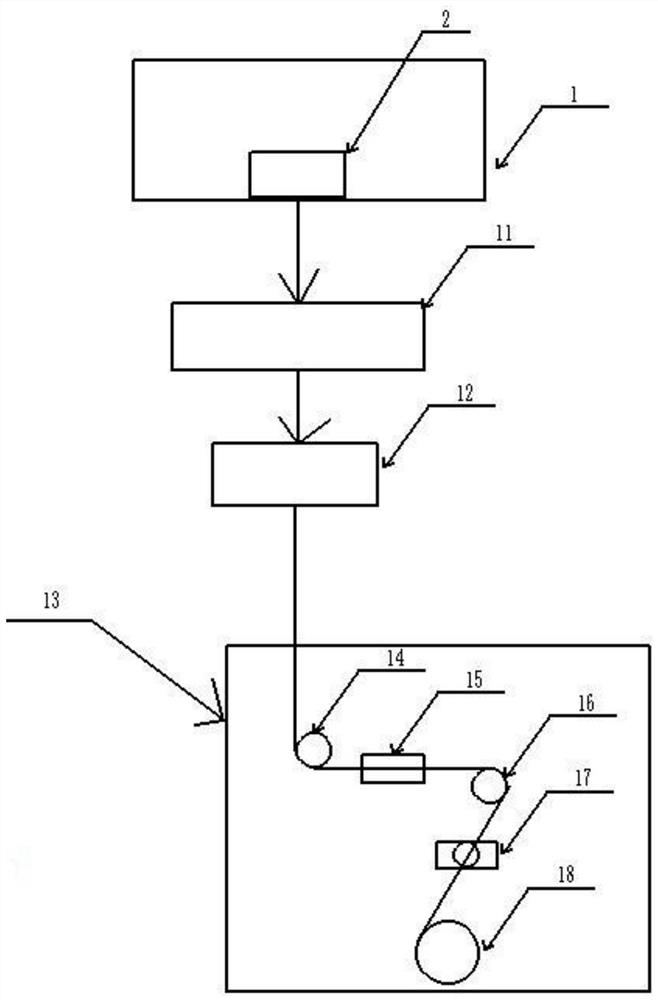

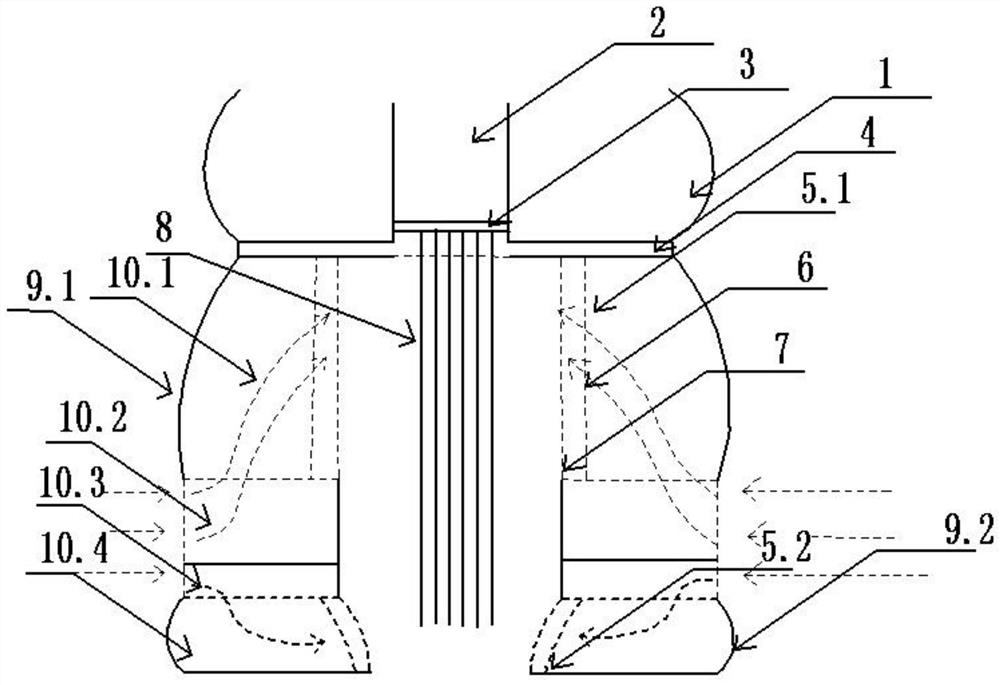

[0039] like Figures 1 to 2 As shown in the figure, a production equipment for low linear density polyester fiber includes a spinning box 1 (used to keep the internal device of the box warm) and a cooling device 11 (used for melt extrusion) arranged in sequence from top to bottom fiber after cooling), oiling device 12 (for oiling and moisturizing the fiber tow 8) and godet device and winding device (for winding the fiber tow 8, which is then packaged into a shaped cake) ;

[0040] A spinning assembly is arranged inside the spinning box 1, and the spinning assembly includes a melt filter chamber 2 and a spinneret 3 located below it;

[0041] The cooling device is a dual air box combined ring blowing cooling device, which consists of upper and lower ring blowing boxes; the upper ring blowing box 9.1 has an upper air chamber 10.1 and a first air chamber 10.2 from top to bottom, and the lower ring blowing box 9.2 is inside There are a second air chamber 10.3 and a lower air cham...

Embodiment 2

[0046] A kind of preparation method of low linear density (6dtex / 6f) polyester fiber, adopts the equipment of embodiment 1, specifically comprises the following steps:

[0047] (1) Melt extrusion: metal sand and a metal filter screen are loaded into the melt filter chamber in the spinning assembly to filter the melt, and the filtered melt is extruded into primary fibers from the spinneret, wherein, The extrusion temperature is 298℃;

[0048] (2) Cooling and solidification: The primary fibers extruded from the spinneret are cooled and formed by a cooling device, wherein the cooling air temperature is 19 ° C, the air humidity is 75%, the air supply air pressure is 800 Pa, and the length of the cooling zone in the upper air chamber is 180mm, and the length of the cooling zone in the lower air chamber is 150mm;

[0049] (3) Cluster oiling: the cooled and formed tows are then clustered and oiled and wetted by the oiling device, wherein the height of the oil frame is 600mm, and the...

Embodiment 3

[0061] A preparation method of low linear density polyester fiber (6.6dtex / 6f), using the equipment of embodiment 1, specifically comprises the following steps:

[0062] (1) Melt extrusion: metal sand and a metal filter screen are loaded into the melt filter chamber in the spinning assembly to filter the melt, and the filtered melt is extruded into primary fibers from the spinneret, wherein, The extrusion temperature is 298℃;

[0063] (2) Cooling and solidification: The primary fibers extruded from the spinneret are cooled and formed by a cooling device, wherein the cooling air temperature is 20 ° C, the air humidity is 76%, the wind pressure at the spinning position is 700 Pa, and the length of the cooling zone in the upper air chamber is 185mm, the length of the cooling zone in the lower air chamber is 155mm;

[0064] (3) Cluster oiling: the cooled and formed tows are then clustered and oiled and wetted by the oiling device, wherein the height of the oil frame is 600mm, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com