Optical fiber connector

An optical fiber connector and optical fiber technology, which is applied in the direction of coupling of optical waveguides, can solve problems such as the inability to provide tension, and achieve the effect of convenient operation and good market application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

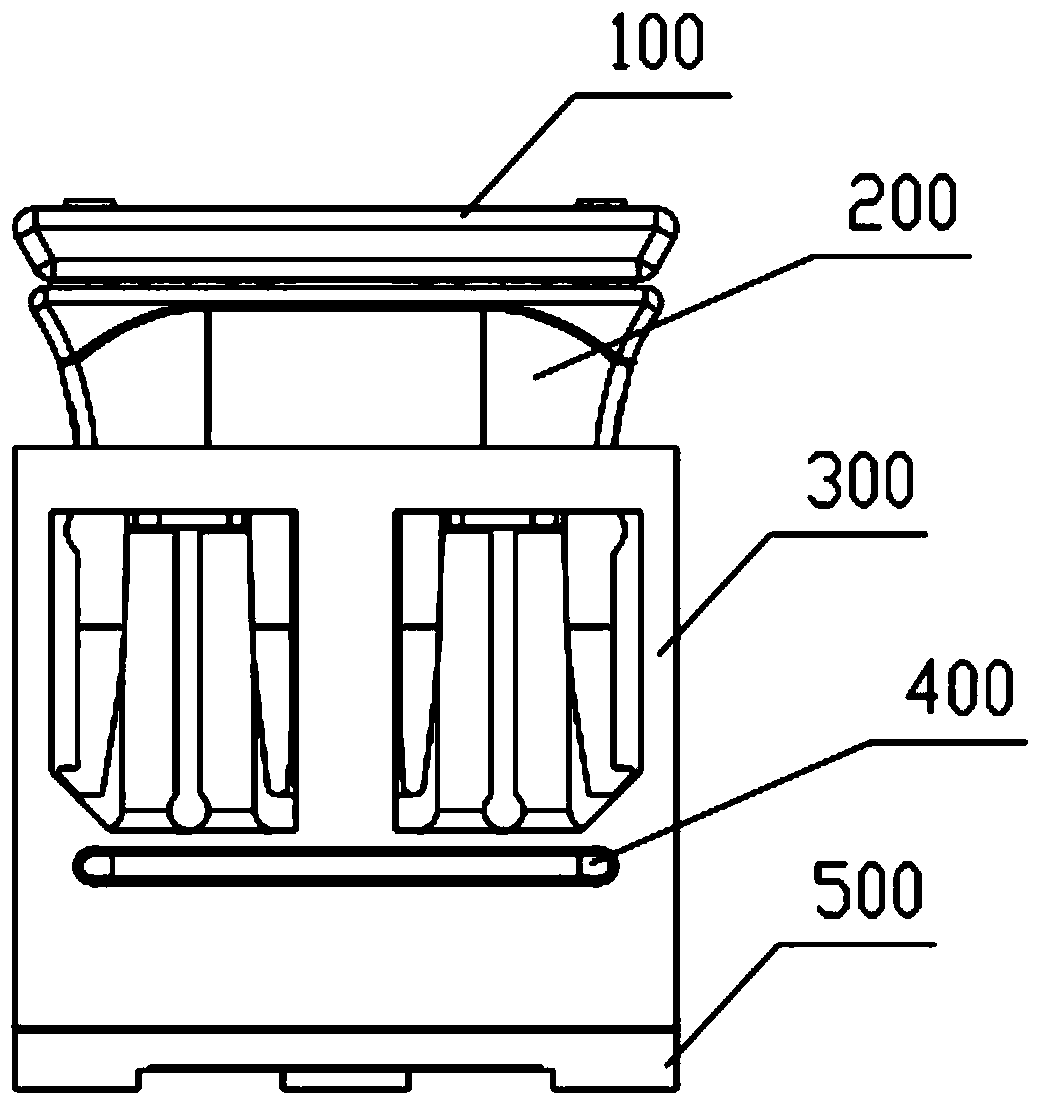

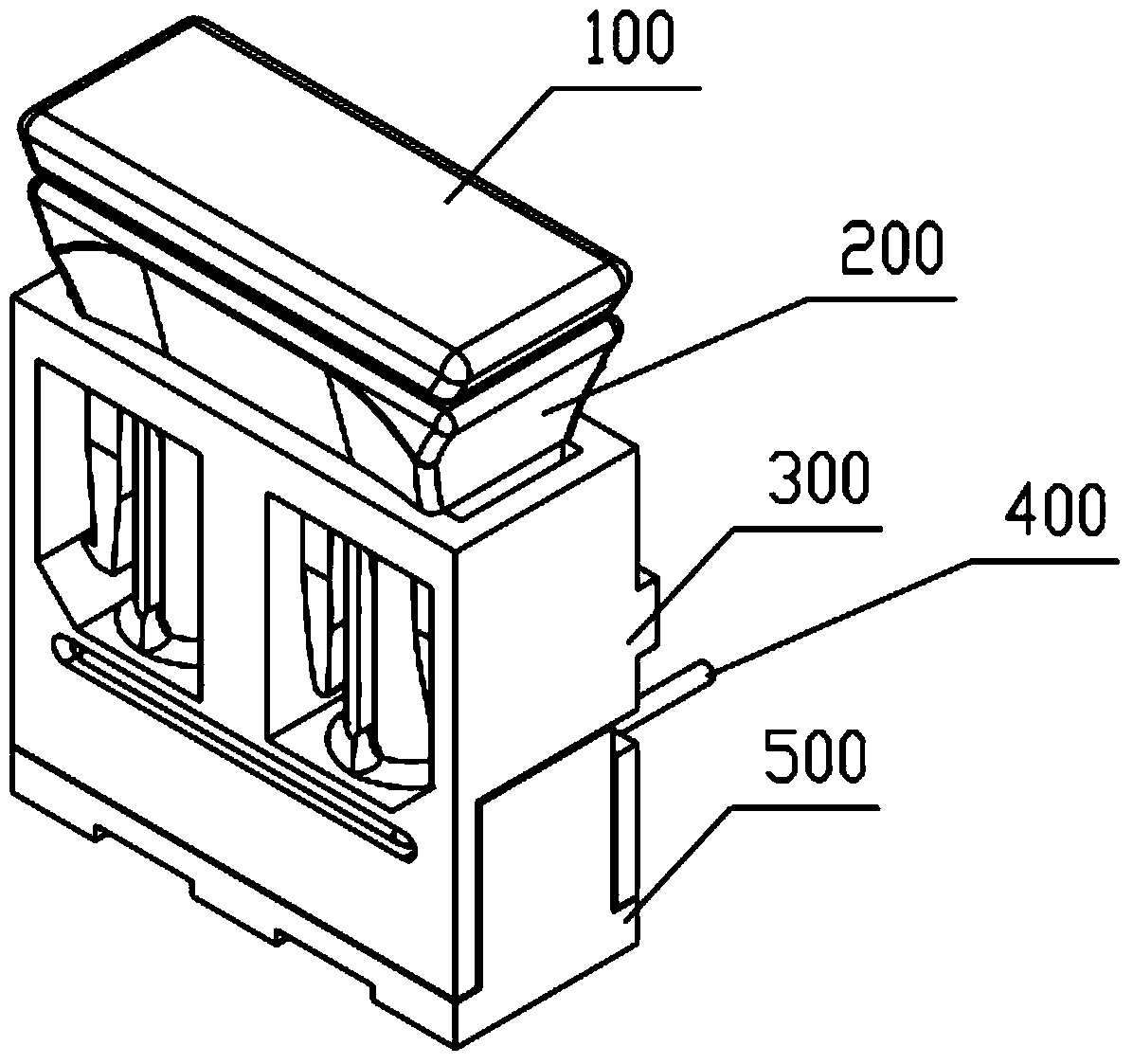

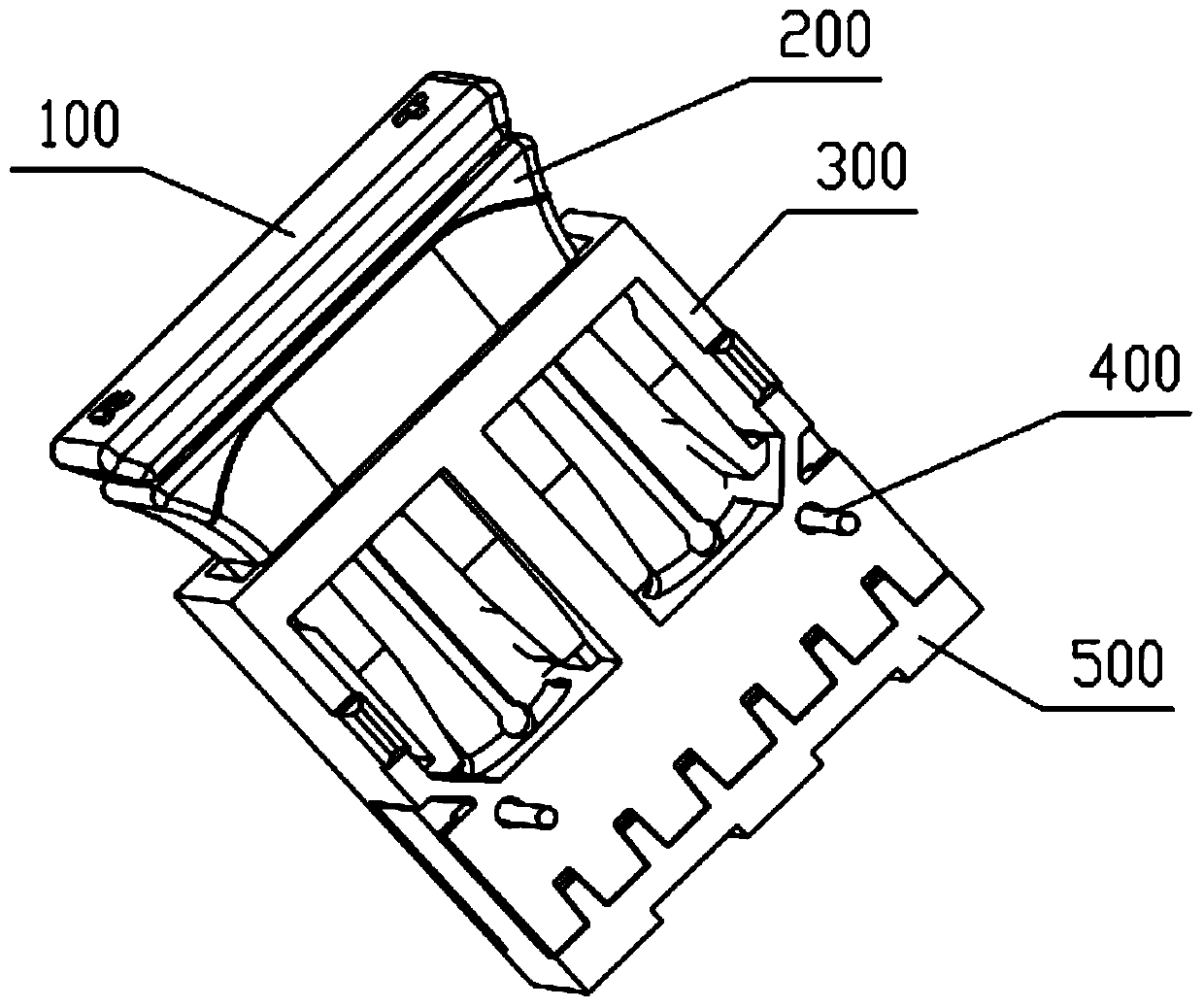

[0033] Such as figure 1 As shown, one embodiment of the present invention is an optical fiber connector, which includes: a main body 300, a clamp 200 and a rear cover 500, preferably, as figure 1 , figure 2 and image 3 As shown, the optical fiber connector also has a dust plug 100 and a fixed pin 400 . Preferably, the clamp, the main body and the rear cover are all plastic parts. Preferably, the dust plug is also a plastic part. And / or, the fixing pin is a metal part or a plastic part.

[0034] For example, another embodiment of the present invention is an optical fiber connector, which includes a clamp, a main body and a rear cover. The main body is provided with a cavity for placing an external pair of optical transceiver devices; the back cover is snapped and fixed with the main body for fixing the pair of optical transceiver devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com