[0004] Both of the above two devices are modified from standard belt conveyors. In order to meet the

layout of the drive mechanism and tension redirection mechanism of the upper and lower

layers of equipment, the drive mechanism of the

belt conveyor on the upper layer of the belt conveyor has to be transferred to the lower layer. The height between the tensioning and reversing mechanisms of the belt conveyor (especially the driving mechanism and the tensioning mechanism of the lower belt conveyor) increases, and the difficulty of equipment installation increases. As the height of the equipment increases, the safety of equipment operation, The stability is correspondingly reduced, and because the height of the equipment increases, the height of the conveying roadway also needs to be increased accordingly, which increases the difficulty of roadway construction and investment costs

At the same time, its driving device, tensioning and redirecting mechanism, and the frame are too wide, which needs to occupy the

pedestrian or inspection passage of the roadway, which will bring inconvenience to the passage of personnel, equipment maintenance and material transportation in the future.

In some equipment, the tensioning redirection mechanism is set at the

tail of the belt conveyor to reduce the height of the tensioning mechanism, so as to save roadway investment. However, due to the long distance between the tensioning redirection mechanism and the driving mechanism, it takes a while to provide tension. , so when the equipment is started, the tension between the tape and the roller of the driving mechanism is small, resulting in small friction, and the tape is prone to slipping

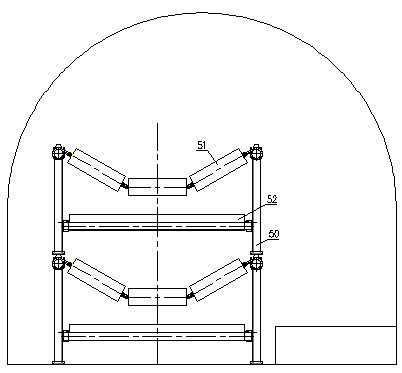

[0005] The suspended double-layer belt conveyor is to arrange two suspended belt conveyors up and down on the same roadway floor, such as figure 2 As shown, the two corresponding legs 50 on both sides of the tape are connected by the upper and lower

layers of grooved rollers 51 and the lower rollers 52. Since the grooved rollers 51 are suspended, the distance between the upper and lower tapes is small, and double-layer installation The height of the rear equipment is low, the requirements for the roadway are not high, and its structure is relatively simple and economical; however, because the hanging idler 51 cannot be installed with a self-aligning idler, and the resistance of the idler is large, the

failure rate of the equipment is high, the belt is easy to run off, and the equipment

High energy consumption and low conveying efficiency; at the same time, due to the high center of gravity of the double-layer belt conveyor and the structure of its hanging idler rollers, the idler rollers are in the form of activities. The rollers 51 and 52 (especially the upper rollers) will swing with the external force and cause the vibration and deformation of the frame, which poses a great safety

hazardSince there is no tape to prevent the tape from being carried on the lower layer of the concave arc section (it is lifted when the tape is tightened and moved from bottom to top), and the idler 51 has no fixed hanging structure, the equipment cannot realize concave arcs, convex arcs, etc. Running under the condition of variable slope, only two-point straight-line conveying can be realized; the outrigger 50 is connected with the rectangular frame by fixing bolts. Due to the complex underground

terrain, the height and spacing of the outriggers of the belt conveyor are greatly affected by

terrain changes, and the fixing bolts The connection cannot be adjusted accordingly, resulting in uneven belt surface of the belt conveyor. At the same time, it is inconvenient to install, adjust, maintain and disassemble the rectangular frame of the equipment and the outrigger 50

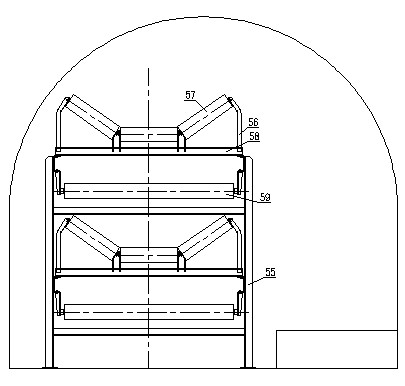

[0006] The fixed double-layer belt conveyor is to arrange two ordinary belt conveyors up and down on the same roadway floor, such as figure 1 As shown, the corresponding two supporting legs 55 on both sides of the

adhesive tape are provided with upper and lower two-layer mounting frames 56, and each layer of mounting frames 56 is connected by a grooved roller 57, a linear support frame 58 and a lower roller 59. After installation The height of the equipment is high, the potential safety hazards of the equipment are large, and the stability is poor. At the same time, the height of the ordinary roadway cannot meet the needs of the equipment, and the roadway needs to be increased to install

Since there is no prevention of the belt on the lower layer of the concave arc section (it is lifted when the tape is tightened and moved from bottom to top), the equipment cannot operate under conditions of variable slopes of more than 6° such as concave arcs and convex arcs; the lower idler roller 59 is installed in the form of a card slot, and the installation shafts at both ends of the lower idler 59 are easy to jump out of the slot during operation, and the lower idler is prone to fall; The

terrain is complex, the height and spacing of outriggers are greatly affected by terrain changes, and the fixed

bolt connection cannot be adjusted accordingly, resulting in uneven belt surface of the belt conveyor. It is inconvenient to disassemble; the above-mentioned belt conveyors have seriously restricted the increase of coal mine output, so coal mine enterprises urgently need a conveyor that saves space, has a large transport capacity, and has high safety performance

Login to View More

Login to View More  Login to View More

Login to View More