Machining clamp of cylinder cover blank adopting robot feeding and discharging mode

A robot and fixture technology, applied in the field of tooling and fixtures, can solve the problems of large casting blank shape error, workpiece collision, and affecting the normal production of the production line, and achieve the effect of resisting rough machining cutting force and preventing workpiece displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

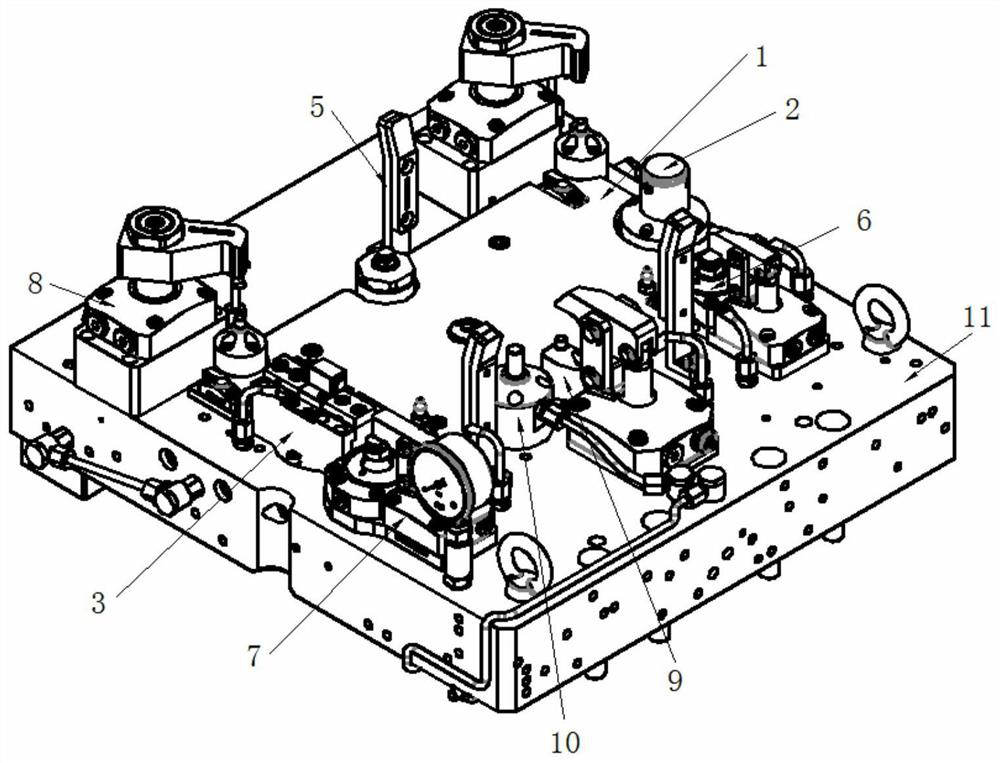

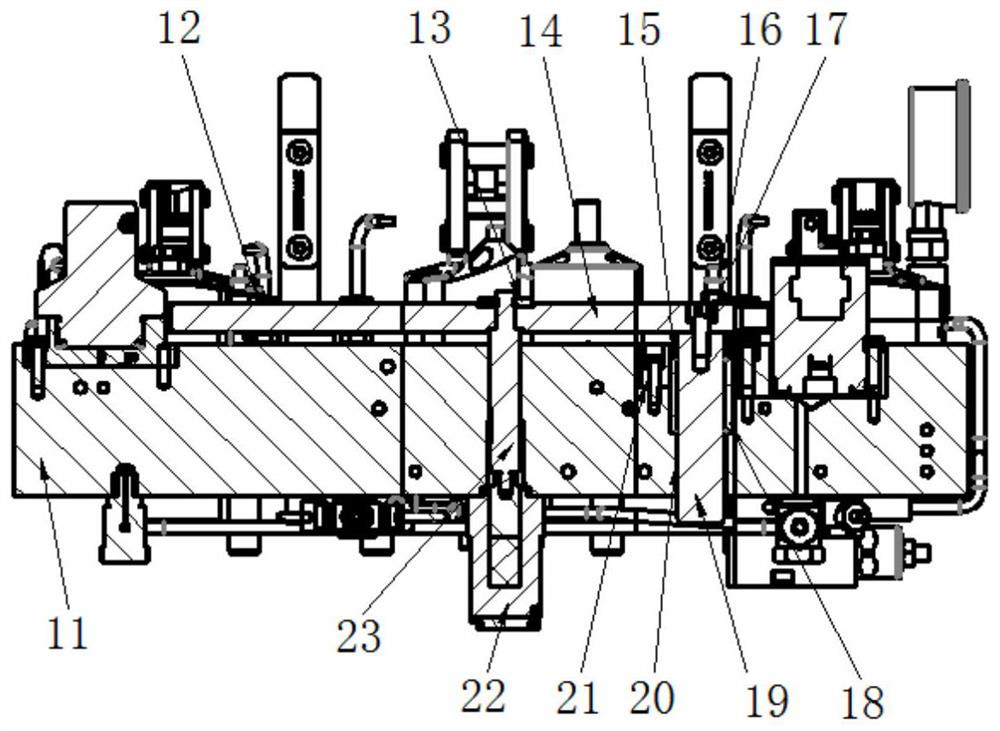

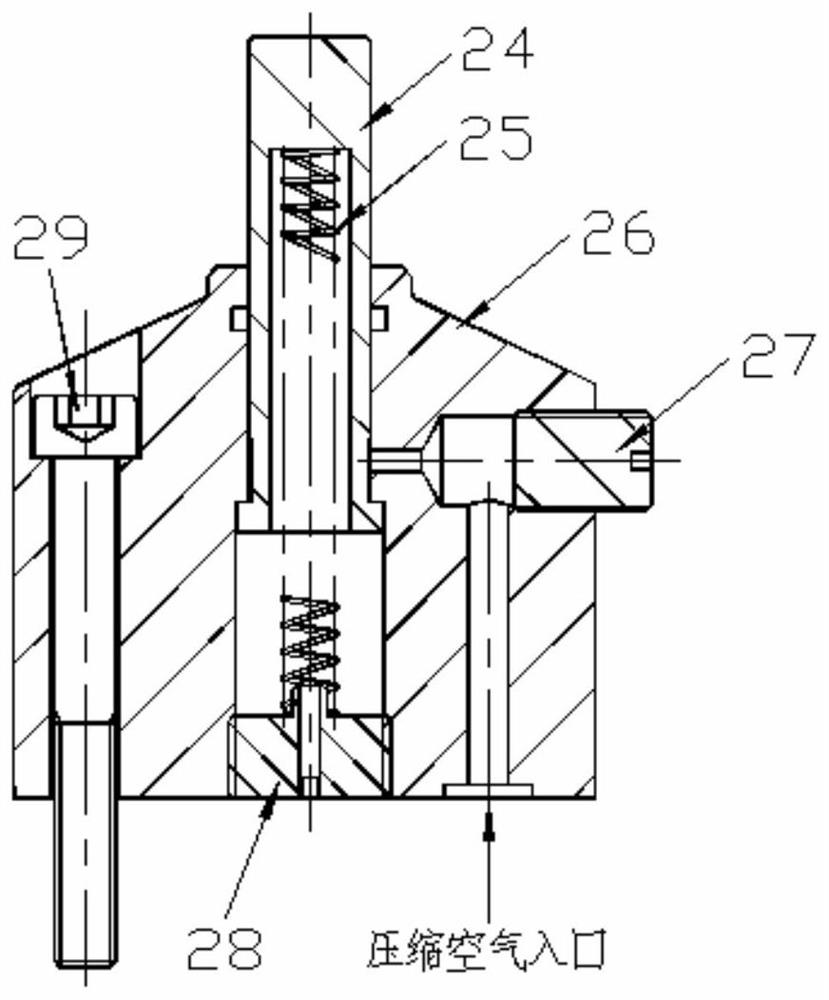

[0029] see Figure 1-4As shown, a processing fixture for a cylinder head blank that adopts a robot loading and unloading method includes a fixture body 11, a positioning assembly 31, a clamping element 32, and an equipment control system 33. The equipment control system 33 is used to control the movement of the lifting pallet assembly 1. Lifting, the upper end of the fixture body 11 is provided with a lifting pallet assembly 1, and the lifting pallet assembly 1 includes a supporting plate 14, a supporting mounting seat 21, a spacer 12, a thick guide nail 16, a guide rod 19 and a linear cylinder 22, and the rough The guide nails 16 are used for rough positioning. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com