On-load installation method for small friction winch for winding of multi-layer steel wire rope of hoister

An installation method and steel wire rope technology are applied in transportation and packaging, lifting equipment in mines, etc., which can solve problems such as the failure of the lower steel wire rope, and achieve the effects of increased service life, tight combination, and balanced force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

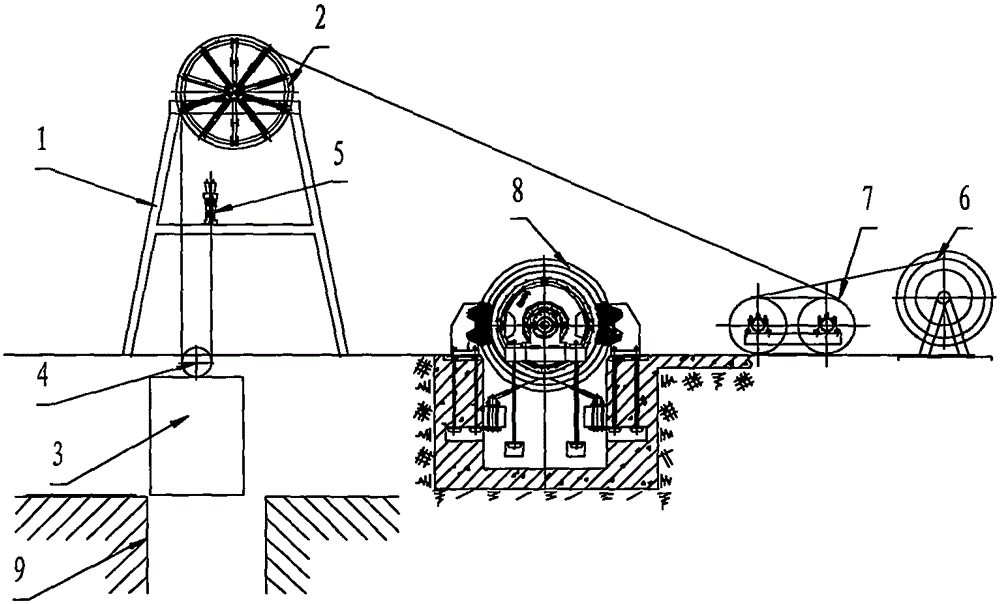

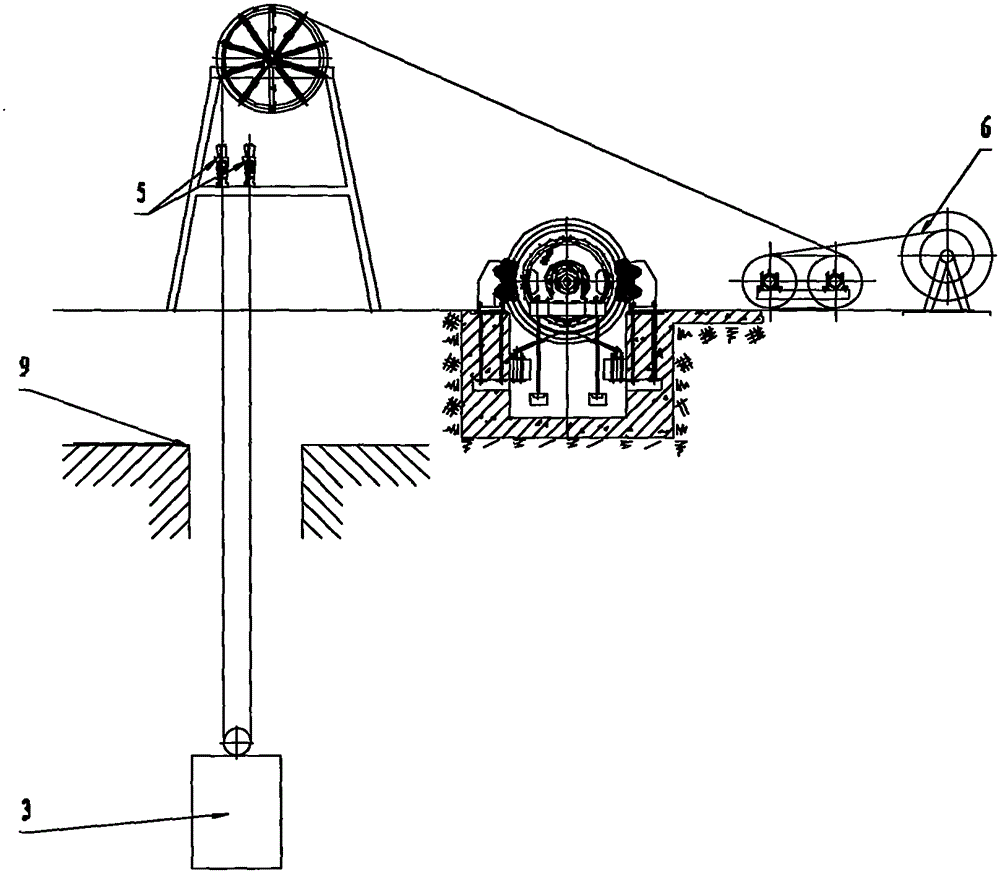

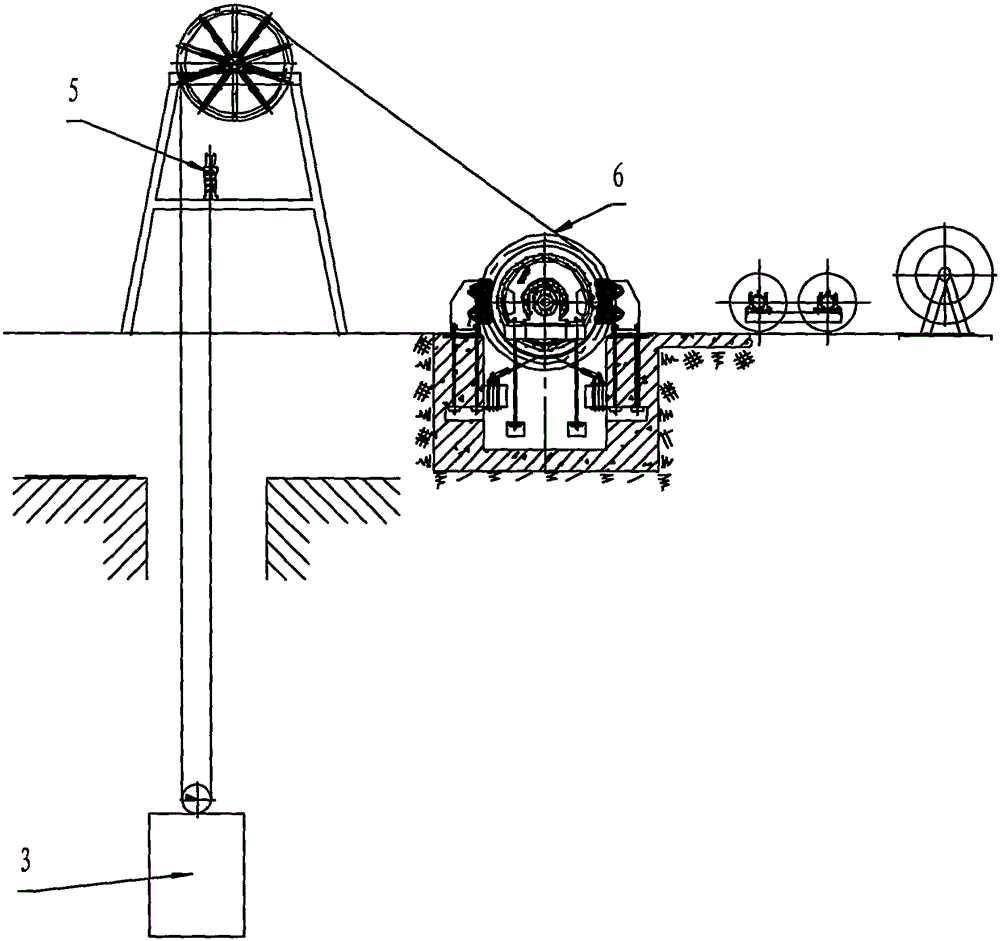

[0026] A derrick 1 is correspondingly arranged above the wellhead 9, a sky wheel 2 is arranged above the derrick 1, and the sky wheel 2 is vertically arranged corresponding to the wellhead 9; a friction trolley 7 is arranged on one side of the derrick 1, and a wire rope reel 6 is arranged on one side of the friction trolley 7; the friction trolley 7 and the derrick 1 A hoist 8 is arranged between them; the sky wheel 2 is arranged on the same line as the friction trolley 7, the hoist 8 and the wire rope reel 6; A wire rope head is set on the top, and a lifting container 3 is set below the wire rope on the wellhead 9 corresponding to the rope clamping device 5; the container moving pulley 4 is set in the upper center of the lifting container 3; ; Set the clamping buckle 10 between the wire rope head and the lifting container 3; when the wire rope is installed, the lifting container 3 is lifted while the wire rope is wound on the hoisting machine 8 drum with load.

Embodiment 2

[0028] The wire rope head of the wire rope roll 6 is pulled out and wound on the friction trolley 7, and the wire rope roll 6 is driven by rotating the friction trolley 7 to pull out the wire rope and wrap it on the sky wheel 2; Above; clamp the wire rope rope head in the rope head rope clamping device 5 above the horizontal frame; drive the wire rope into the well by the weight of the friction trolley 7 and the lifting container 3, and stop the rotation when the friction trolley 7 is placed into the well to a preset depth.

Embodiment 3

[0030] The middle wire rope is fixed above the horizontal frame by another rope clamping device 5; then, the tail of the wire rope is removed from the wire rope roll 6, and it is installed and fixed on the hoist 8; after the end of the wire rope is fixed, remove the middle wire rope clamping device 5. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com