Optical coating composite production line of adjustable scraping structure

A production line and coating technology, which is applied to the device, coating, pretreatment surface and other directions of coating liquid on the surface, which can solve the problem of insufficient tension of the optical film, unstable quality of the optical film of the coating solution, and easy to affect the application of the coating solution. And other problems, to achieve a good scraping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

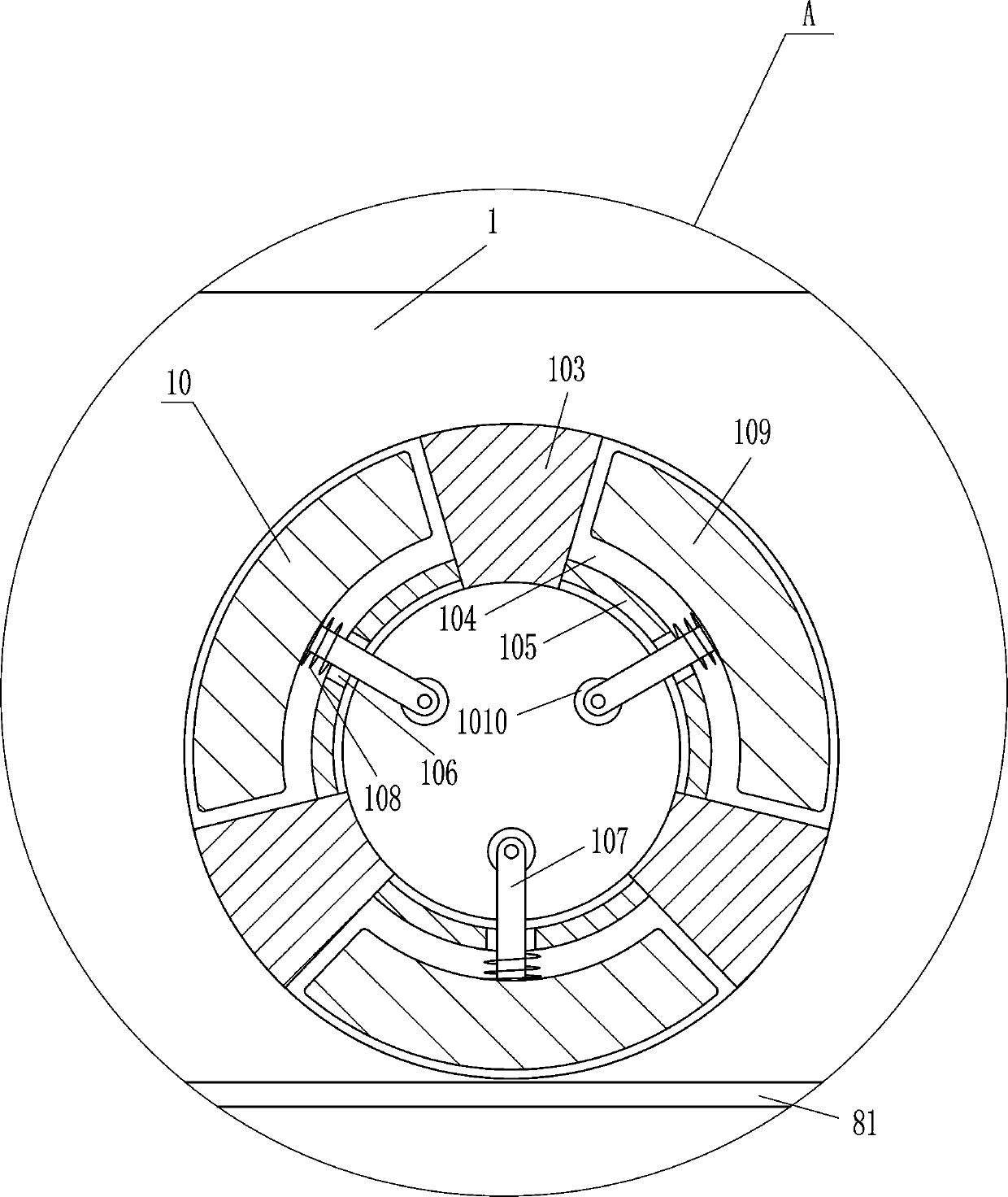

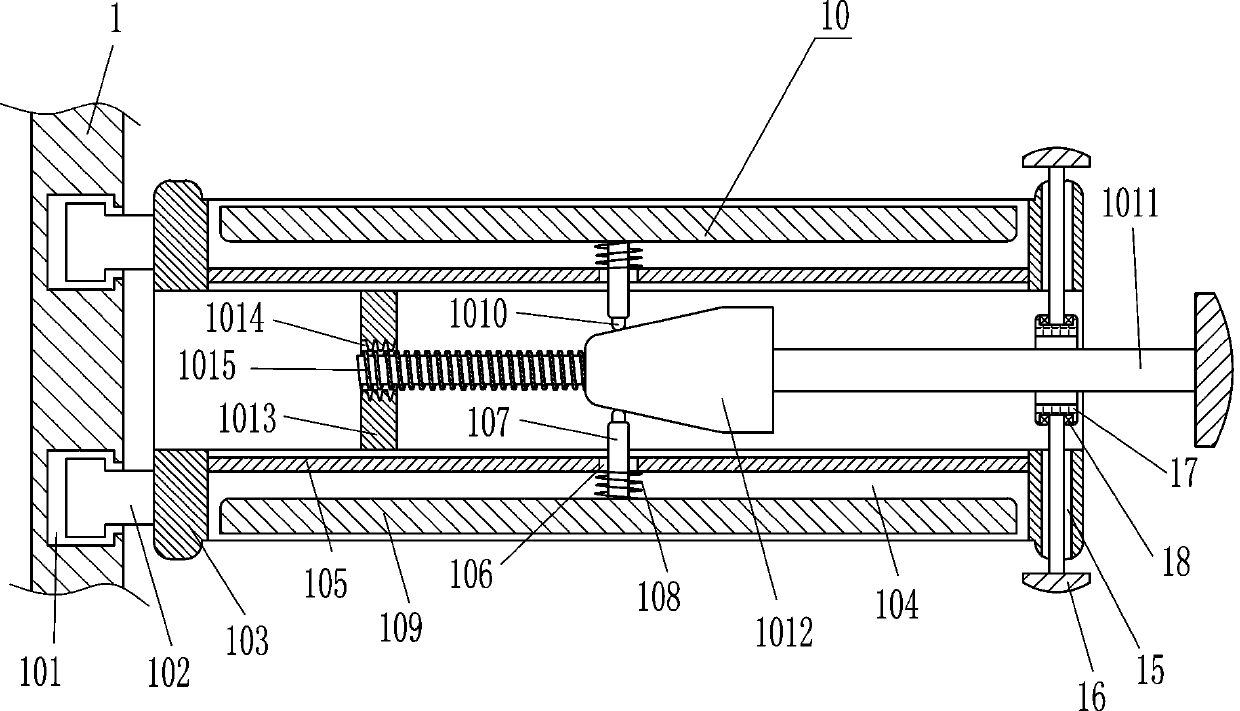

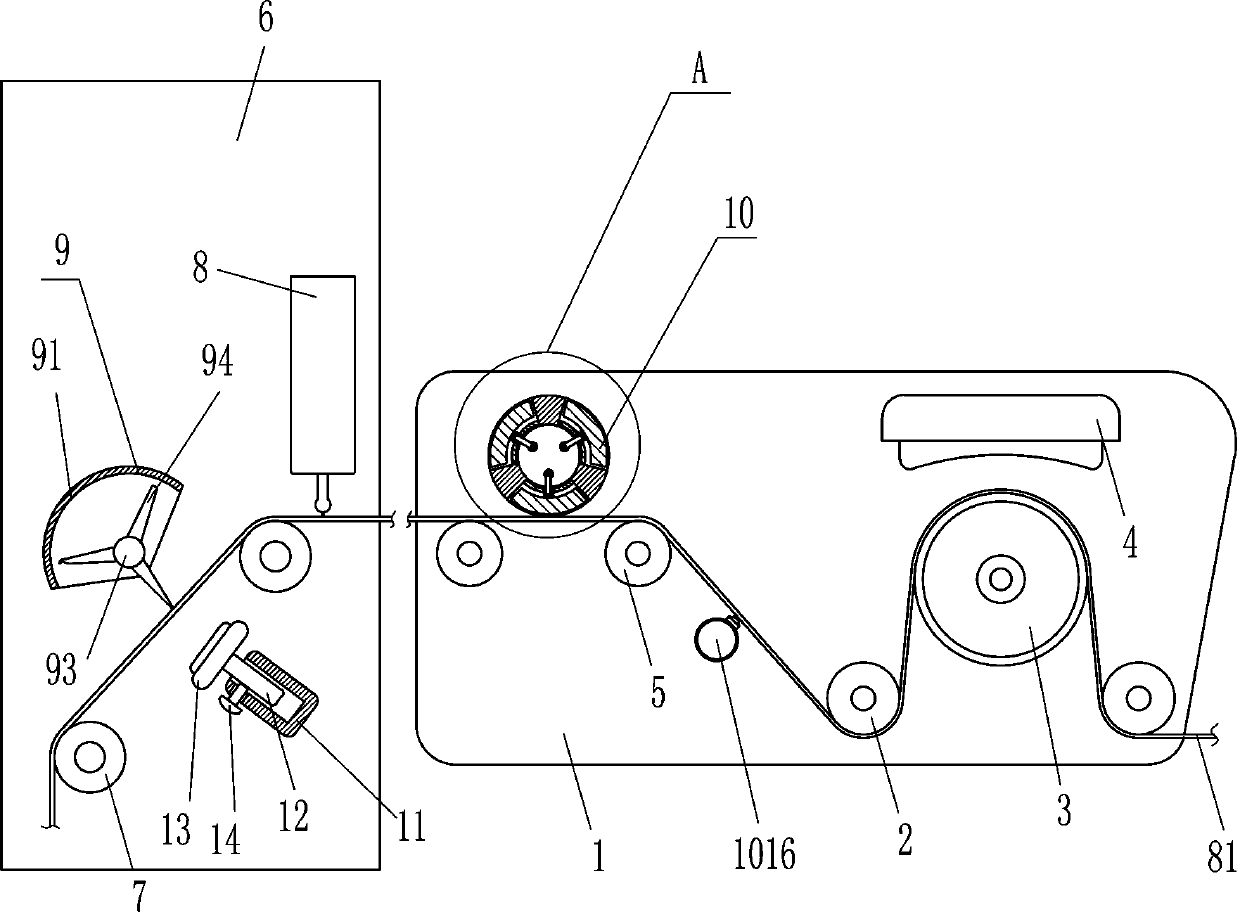

[0017] An optical coating composite production line with adjustable scraping structure, such as Figure 1-3 As shown, it includes a frame 1, a film introduction roller 2, a film cylinder 3, a corona processor 4, a film guide roller 5, a coating treatment plate 6, a film export roller 7, a liquid outlet device 8 and a scraper device 9 , the bottom right side of the front side of the frame 1 is provided with two film introduction rollers 2, and the right side of the front side of the frame 1 is provided with a film cylinder 3, which can increase the corona treatment of the adhesion of the optical film 81 The device 4 is installed on the upper right side of the front side of the frame 1, the corona processor 4 is connected with the frame 1 through bolt connection, the corona processor 4 is located above the film cylinder 3, and the left part of the front side of the frame 1 rotates in the middle The type is provided with two film guide rollers 5, and the left and right sides of t...

Embodiment 2

[0019] An optical coating composite production line with adjustable scraping structure, such as Figure 1-3 As shown, it includes a frame 1, a film introduction roller 2, a film cylinder 3, a corona processor 4, a film guide roller 5, a coating treatment plate 6, a film export roller 7, a liquid outlet device 8 and a scraper device 9 , the bottom right side of the front side of the frame 1 is provided with two film introduction rollers 2, and the right side of the front side of the frame 1 is provided with a film cylinder 3, which can increase the corona treatment of the adhesion of the optical film 81 The device 4 is installed on the upper right side of the front side of the frame 1, the corona processor 4 is located above the film cylinder 3, the middle of the left side of the front side of the frame 1 is provided with two film guide rollers 5, and the coating treatment plate 6 The left and right sides of the lower part of the front side are rotatably provided with film lead...

Embodiment 3

[0022] An optical coating composite production line with adjustable scraping structure, such as Figure 1-4As shown, it includes a frame 1, a film introduction roller 2, a film cylinder 3, a corona processor 4, a film guide roller 5, a coating treatment plate 6, a film export roller 7, a liquid outlet device 8 and a scraper device 9 , the bottom right side of the front side of the frame 1 is provided with two film introduction rollers 2, and the right side of the front side of the frame 1 is provided with a film cylinder 3, which can increase the corona treatment of the adhesion of the optical film 81 The device 4 is installed on the upper right side of the front side of the frame 1, the corona processor 4 is located above the film cylinder 3, the middle of the left side of the front side of the frame 1 is provided with two film guide rollers 5, and the coating treatment plate 6 The left and right sides of the lower part of the front side are rotatably provided with film lead-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com