Middle screw take-up device of reversible belt conveyor

A technology of tensioning device and conveyor, applied in the direction of conveyor, transportation and packaging, etc., to achieve the effect of simple basic requirements, space saving and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

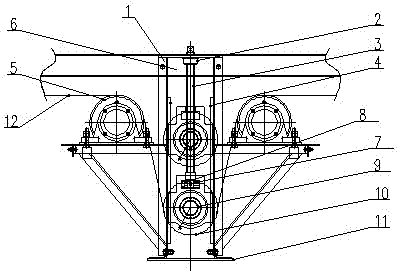

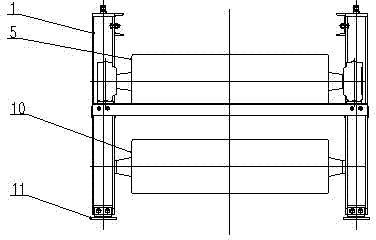

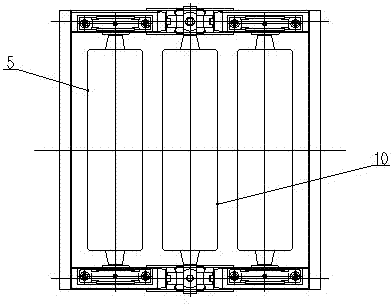

[0015] The following is a detailed description of the present invention in conjunction with the accompanying drawings in order to gain a better understanding:

[0016] The middle spiral tensioning device of the reversible belt conveyor includes a tensioning bracket 1 and a screw 3. The upper end of the tensioning bracket 1 is fixed on the middle bracket 6 with fasteners, and the bottom foot plate 11 is directly welded to the embedded part. Both the left and right ends are equipped with a reversing roller 5 by means of fasteners; there is a fixed guide rail 4 in the middle of the tension bracket 1; one end of the screw 3 is connected with a nut 2 welded on the tension bracket 1 It is connected by a thread pair, and the other end is fixed and can only move up and down along the guide rail 4 on the tensioning bracket 1 and is connected to the seated bearing 9 by means of a retaining ring 7 and a screw 8; Tightening roller 10; each of the tensioning rollers 10 and reversing rollers 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com