Pre-distributing tension damping device

A damping device and tension technology, applied in thin material handling, transportation and packaging, coiling and other directions, can solve the problems of insufficient steel strip tension, low production efficiency, and reduced steel coil quality, so as to ensure the winding quality, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

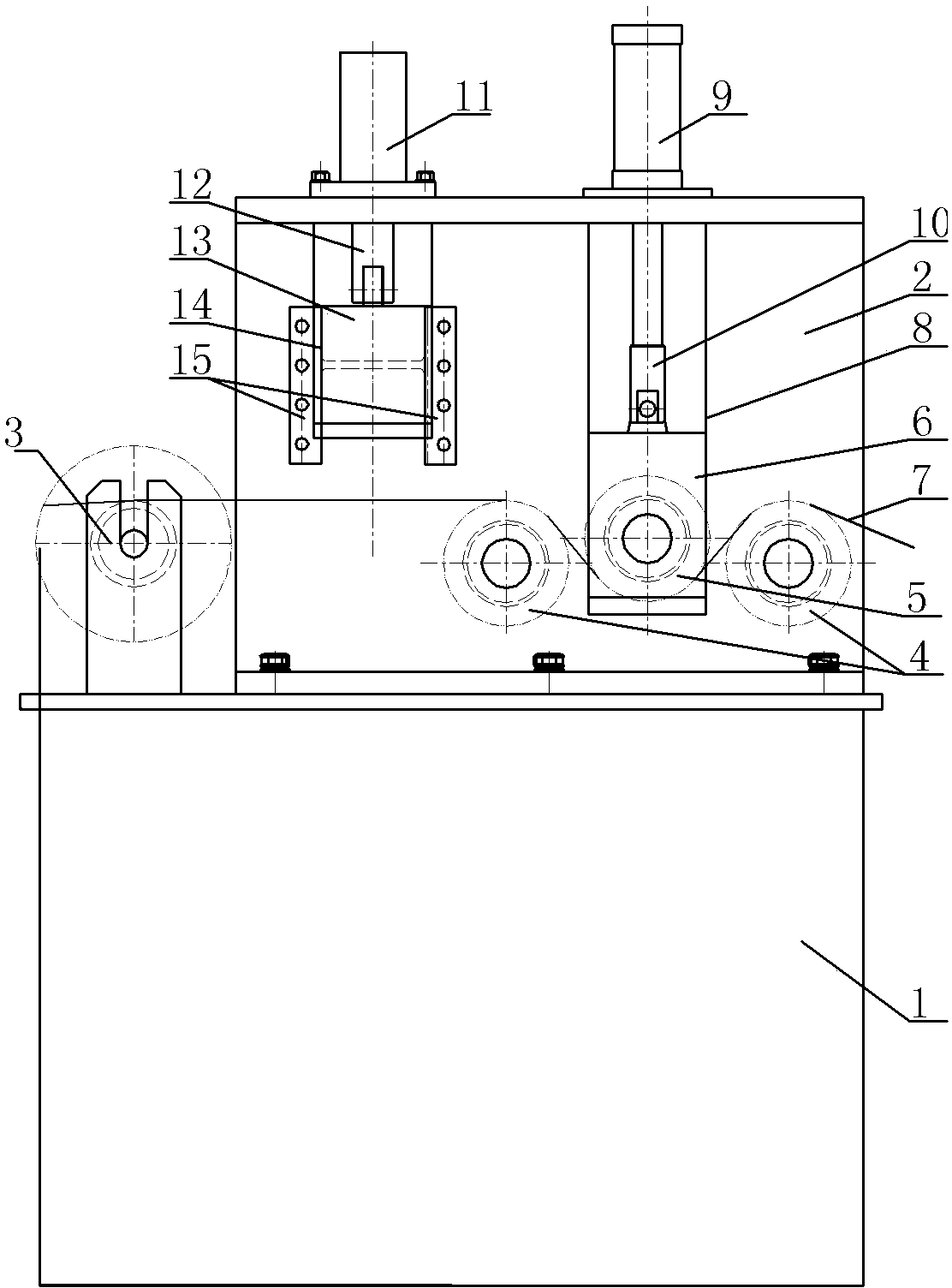

[0007] See figure 1 , which includes a base 1, an archway structure 2 is arranged above the base 1, a guide roller structure 3 is arranged at the front of the archway structure 2, and the guide roller structure 3 is fastened to the upper front portion of the base 1, and the rear portion of the archway structure 2 is arranged Two positioning rollers 4 arranged laterally, a lower pressure roller 5 is arranged between the two positioning rollers 4, the rotation shaft of the lower pressure roller 5 is supported on the two side walls of the lower pressure roller base 6, and the lower pressure roller base 6 The side wall is a convex structure, and the convex structure is clamped in the vertical guide groove 8 of the archway structure 2. A rear hydraulic cylinder 9 is arranged on the rear side of the upper end of the archway structure 2, and the lower piston rod of the rear hydraulic cylinder 9 10 is tightly connected to the upper part of the lower pressure roller base 6, the front s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com