Roller line storage type sand line cutting machine tool

A sand wire cutting machine tool and wire storage technology, which is applied in the direction of grinding machines, fine working devices, and work accessories, can solve the problems of poor flatness of the cutting plane, achieve flatness improvement, convenient and quick replacement of guide wheels, and improve the sanding line. Effect of Cutting Accuracy and Surface Roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

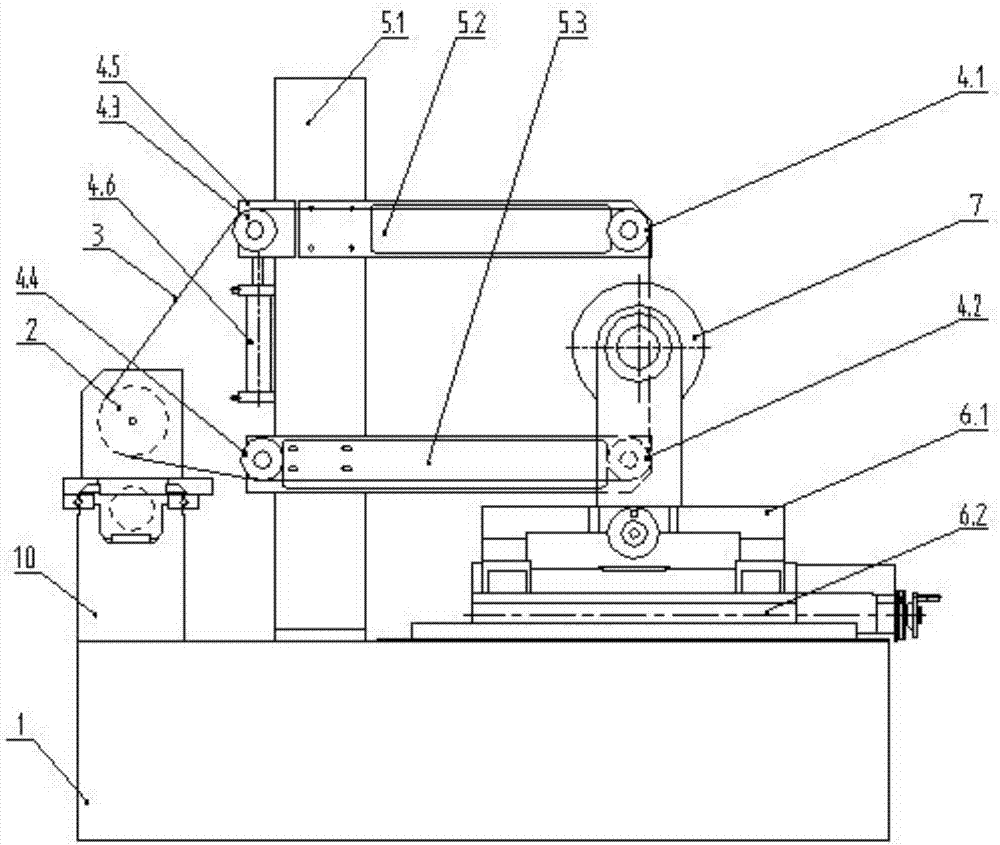

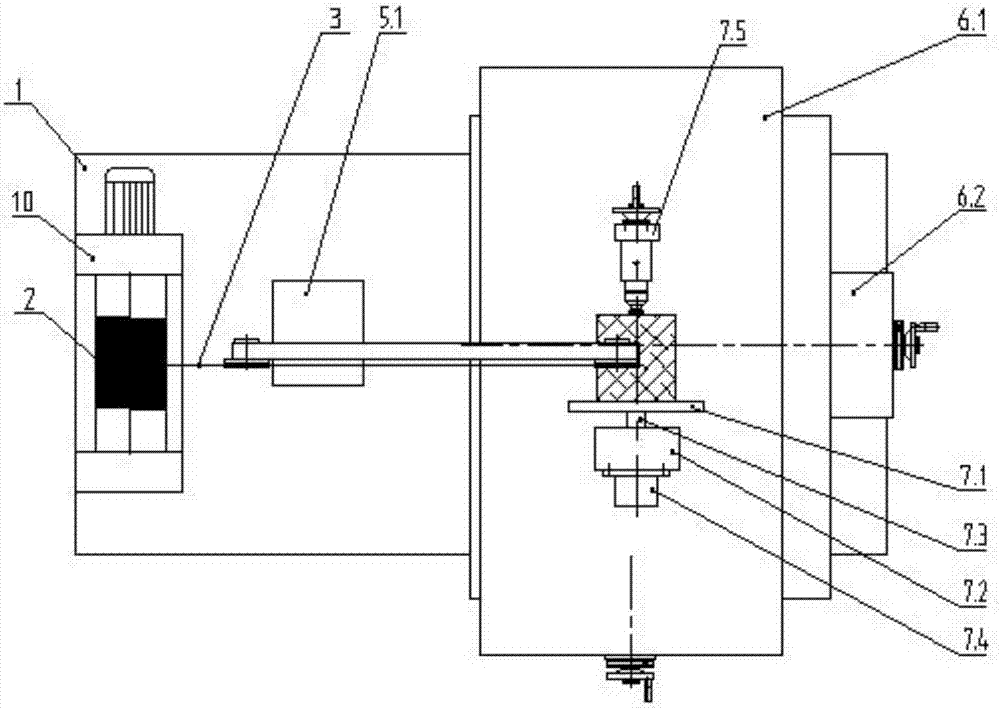

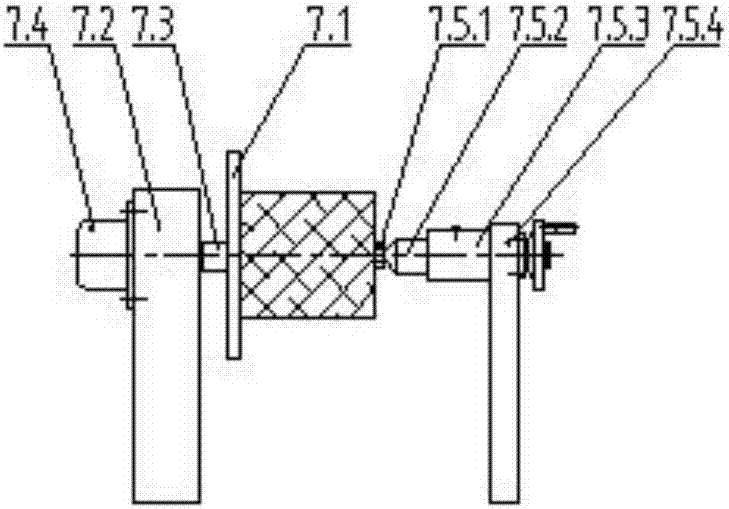

[0028] The drum-storage wire-sand wire cutting machine shown in the accompanying drawings includes a base 1, a wire storage drum 2, a wire storage drum moving part 10, a sand wire 3, a workbench assembly, a guide wheel assembly, and a guide wheel support frame; the workbench assembly, The moving parts 10 of the wire storage barrel are arranged on the base 1 at intervals; the workbench assembly includes a workbench 6.1 and a vertical and horizontal movement mechanism 6.2. On; the guide wheel supporting frame includes a column 5.1, an upper wire frame 5.2, and a lower wire frame 5.3; the column 5.1 is arranged on the base 1, between the moving part 10 of the wire storage barrel and the workbench assembly; the upper wire frame 5.2 and the lower wire frame 5.3 are both The elongated components are arranged in parallel at intervals up and do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com