Method for taking up and drawing a multifilament during melt-spinning, and apparatus for carrying out said method

A technology of multifilament yarn, melt spinning, applied in the field of equipment for drawing and stretching multifilament yarn during melt spinning and implementing this, to achieve the effect of eliminating internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

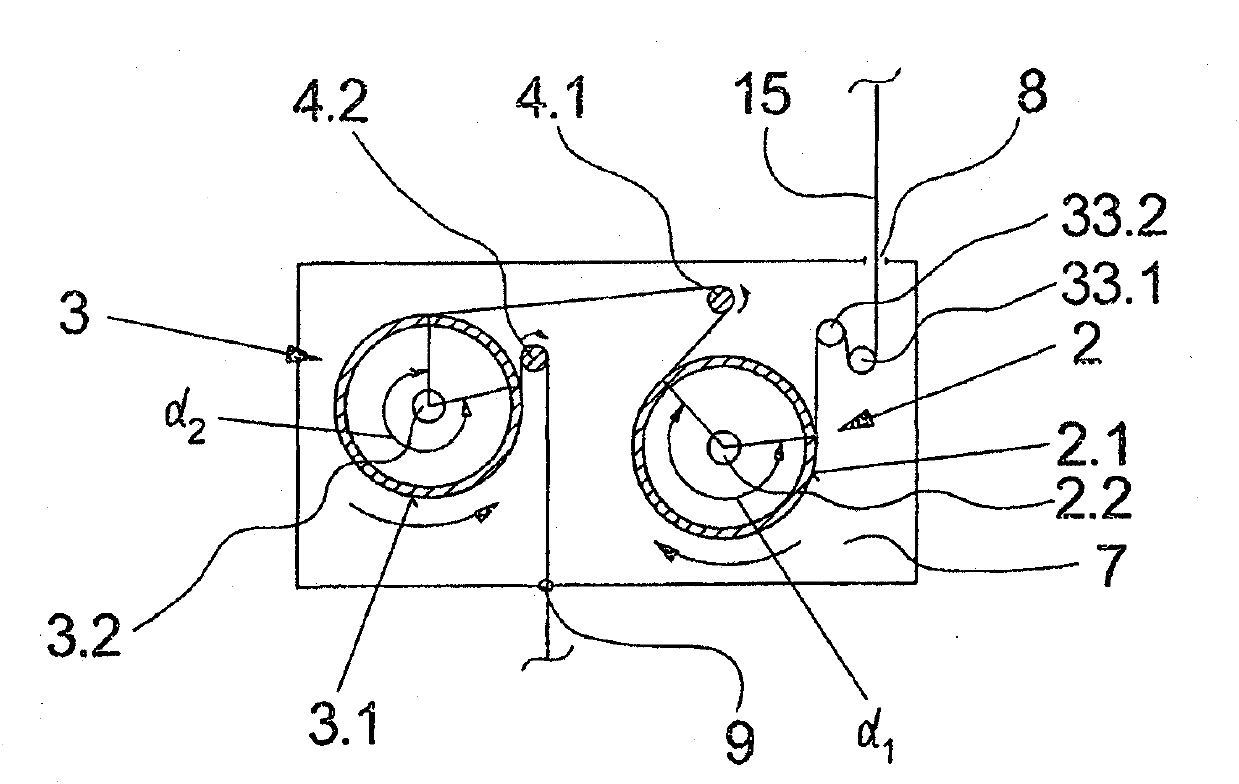

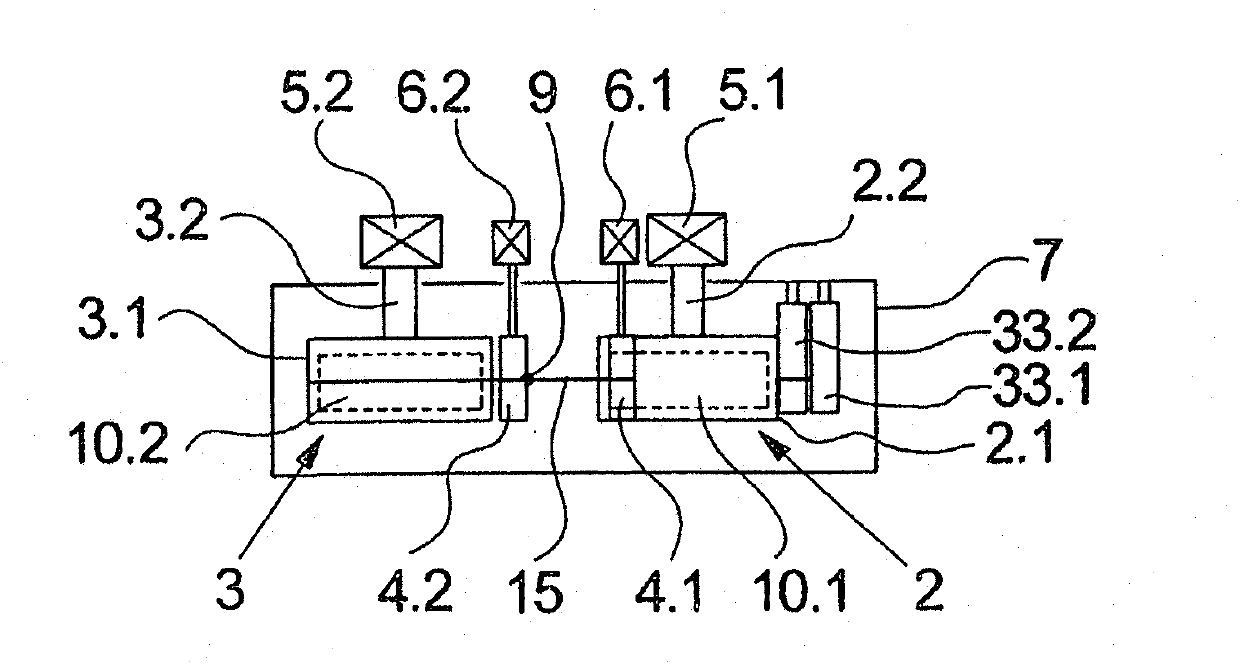

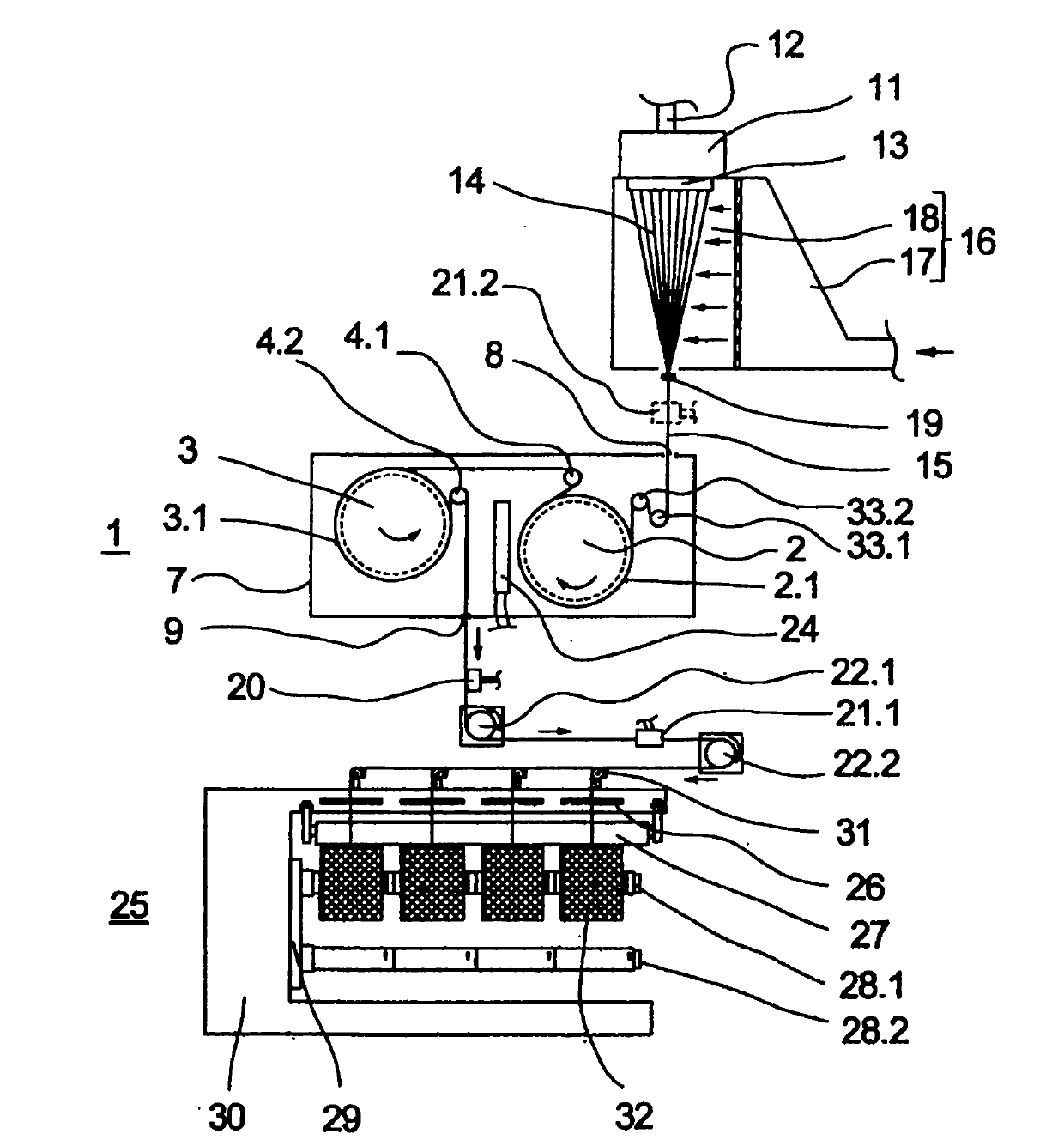

[0037] in the attached figure 1 with 2 A first embodiment of a device according to the invention for carrying out the method of the invention is shown in . in the attached figure 1 The embodiment is shown schematically in side view and in the accompanying figure 2 is schematically shown in top view. The following description applies to both figures as long as no explicit reference is made to one of the figures.

[0038] This exemplary embodiment has a withdrawal godet 2 for the withdrawal of the yarn 15 by a spinning device not shown here. The withdrawal godet 2 has a hollow-cylindrical guide housing 2.1 and a drive shaft 2.2 connected to the guide housing 2.1 in a rotationally fixed manner. The drive shaft 2.2 is coupled to a godet drive 5.1. A heating device 10.1 is arranged inside the guide housing 2.1 from which the godet 2 is withdrawn, by means of which the guide housing 2.1 can be heated.

[0039] The outer diameter of the guide housing 2.1 of the extraction god...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com