Production method of guide bearing

A production method and guide bearing technology are applied in the production field of non-metal guide bearings of submerged pumps, which can solve the problems affecting the service life stability of guide bearings, loss of continuity of fiber cloth layer, and poor surface smoothness of water tank, etc. Shortened production hours, less breakage, and less flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

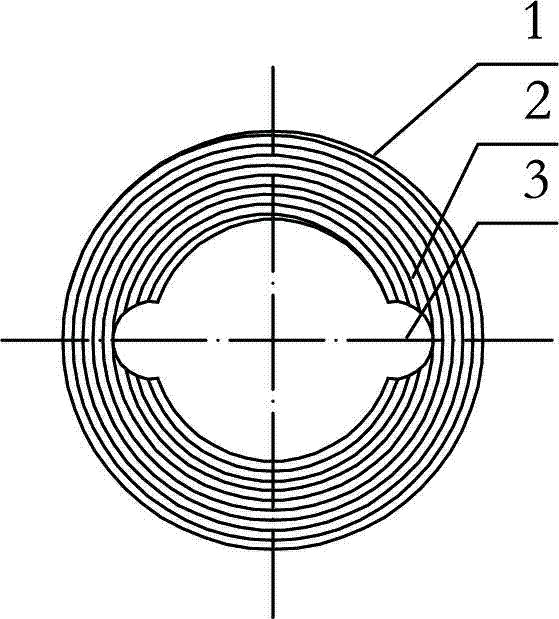

[0026] A production method of a guide bearing, the guide bearing is produced according to the following process:

[0027] 1) On the outer peripheral surface of the cylindrical mandrel base, form a contoured spiral protrusion corresponding to the shape of the spiral water tank on the inner wall of the guide bearing. high helical protrusions;

[0028] 2) Apply a release agent on the surface of the mandrel, the release agent is preferably silicone oil, and other high temperature resistant release agents can also be selected;

[0029] 3) Roll the fiber cloth impregnated with the modified resin on the mandrel coated with the release agent with a tube rolling machine, and reasonably determine the number of layers of the fiber cloth rolled on the mandrel according to the specifications of the guide bearing to be produced;

[0030] 4) Put the core mold wrapped with fiber cloth horizontally into the guide bearing molding cavity of the hot press for hot pressing, the hot pressing tempe...

Embodiment 2

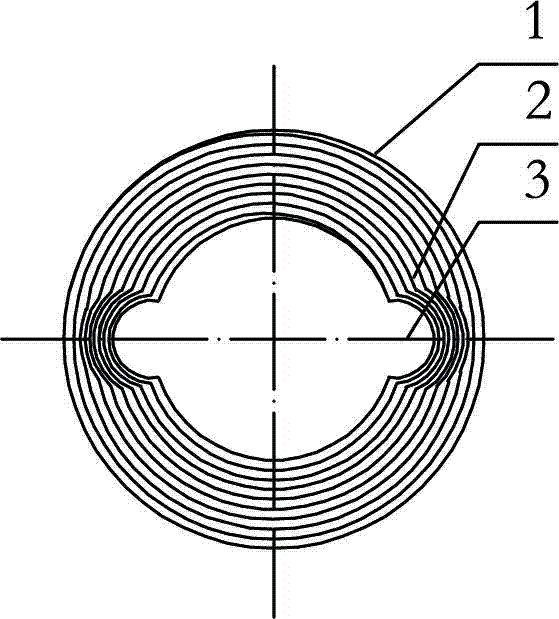

[0037] A production method of a guide bearing, the guide bearing is produced according to the following process:

[0038] 1) On the outer peripheral surface of the cylindrical mandrel base, a contoured spiral protrusion corresponding to the shape of the spiral water tank on the inner wall of the guide bearing is formed. The helix angle of the contoured spiral protrusion is 45 degrees, and the contoured spiral protrusion is a single head, etc. high helical protrusions;

[0039] 2) Apply a release agent on the surface of the mandrel, the release agent is preferably silicone oil, and other high temperature resistant release agents can also be selected;

[0040] 3) Roll the fiber cloth impregnated with the modified resin on the mandrel coated with the release agent with a tube rolling machine, and reasonably determine the number of layers of the fiber cloth rolled on the mandrel according to the specifications of the guide bearing to be produced;

[0041] 4) Put the core mold rol...

Embodiment 3

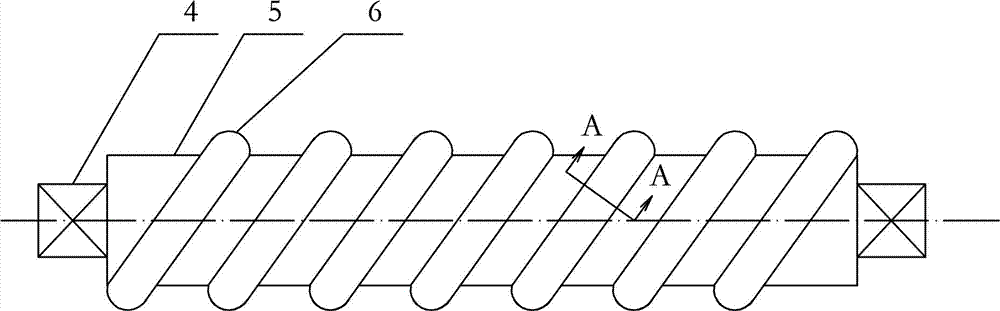

[0047] A production method of a guide bearing, the guide bearing is produced according to the following process:

[0048] 1) On the outer peripheral surface of the cylindrical mandrel base, a contoured spiral protrusion corresponding to the shape of the spiral water tank on the inner wall of the guide bearing is formed. The helix angle of the contoured spiral protrusion is 30 degrees, and the contoured spiral protrusion is double-headed, etc. high helical protrusions;

[0049] 2) Apply a release agent on the surface of the mandrel, the release agent is preferably silicone oil, and other high temperature resistant release agents can also be selected;

[0050] 3) Roll the fiber cloth impregnated with the modified resin on the mandrel coated with the release agent with a tube rolling machine, and reasonably determine the number of layers of the fiber cloth rolled on the mandrel according to the specifications of the guide bearing to be produced;

[0051] 4) Put the core mold wra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com