Wire drawing machine and machining method thereof

A wire drawing machine and wire drawing technology, applied in metal processing equipment, manufacturing tools, grinding workpiece supports, etc., can solve problems such as low wire drawing efficiency, uneven lines, inconsistent line depth, etc., to ensure processing quality, reliability, The effect of high wire drawing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

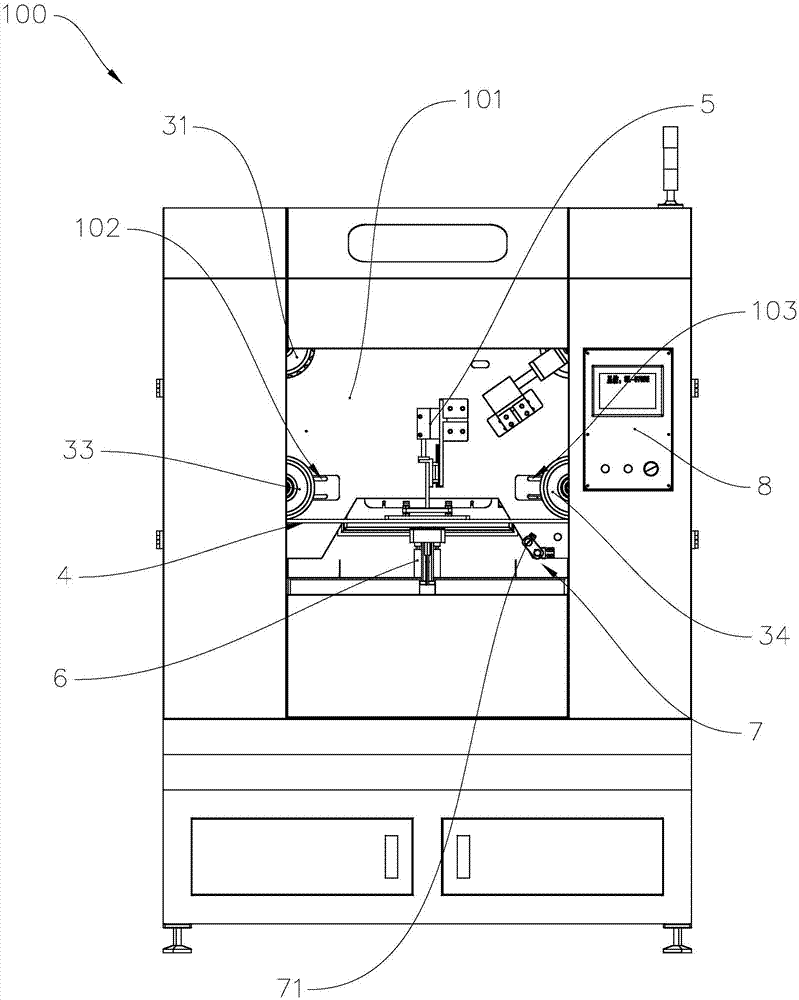

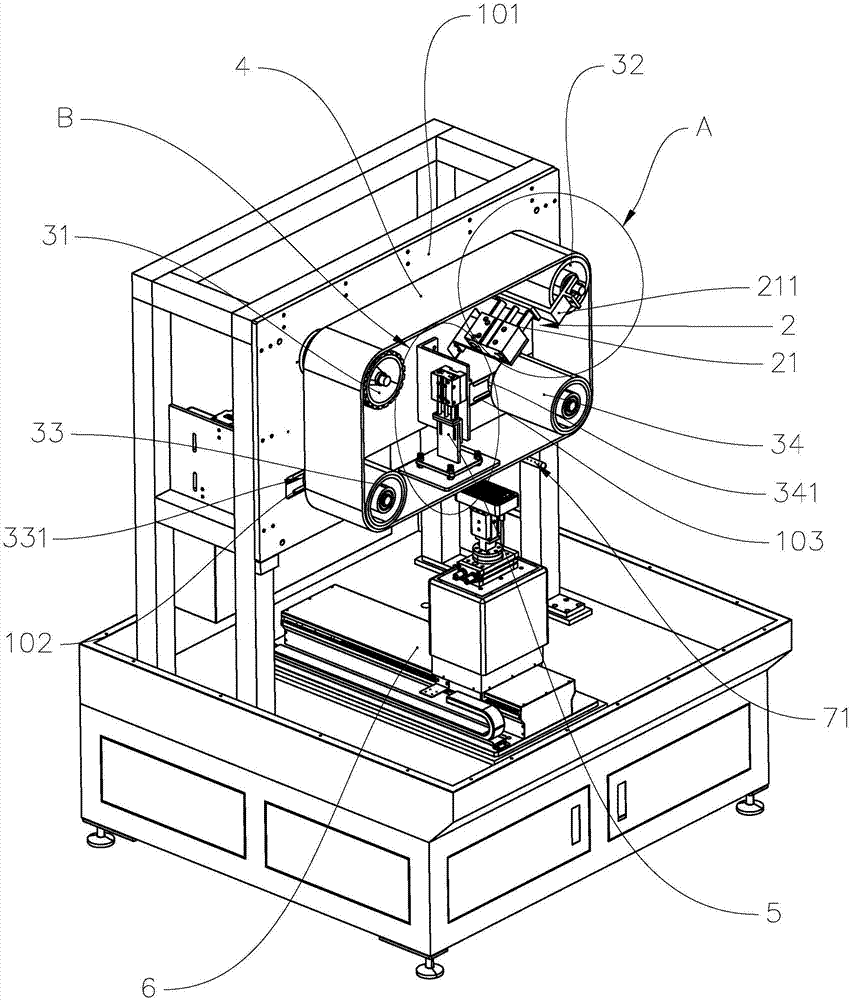

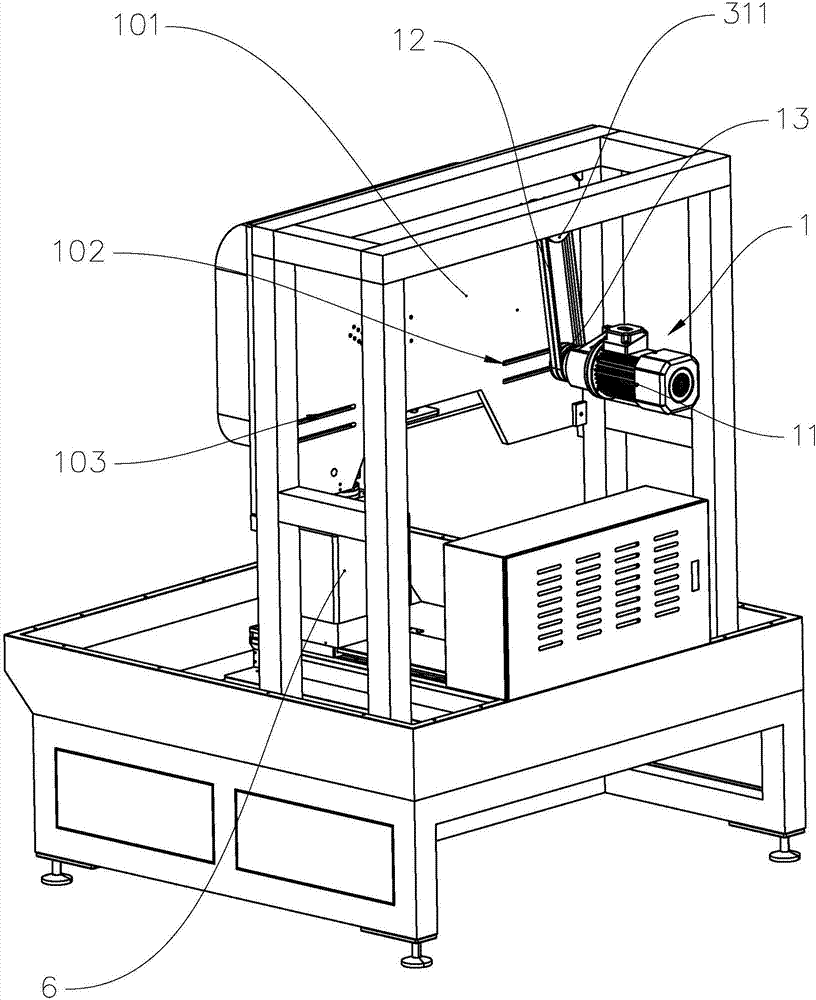

[0032] Drawing machine embodiment:

[0033] refer to Figure 1 to Figure 3 , the wire drawing machine 100 includes a frame 101 , a first driving mechanism 1 , a second driving mechanism 2 , a plurality of rollers, a wire drawing belt 4 , a pressing device 5 , a clamping device 6 , a cooling device 7 and a control system 8 . Wherein, a plurality of roller axes are not on the same straight line.

[0034] Preferably, the number of roller shafts is four, and the first roller shaft 31 is rotatably connected with the frame 101 around its own axis, and the second roller shaft 32 is rotatably connected with the driving end of the second drive mechanism 2 around its own axis. The third roller shaft 33 is rotatably connected to the frame 101 around its own axis, and the fourth roller shaft 34 is rotatably connected to the frame 101 around its own axis. The drawing ribbon 4 is respectively adjacent to the four rollers, and the drawing ribbon 4 is wound around the four rollers.

[0035...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com