Production method and device for solving pre-treatment film pasting exposure line connection and application of production method and device for solving pre-treatment film pasting exposure line connection

A production method and production device technology, applied in the field of PCB manufacturing, to achieve the effect of improving quality, improving efficiency, and increasing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] A production method that can solve the problem of pre-processing film exposure connection includes:

[0097] (1) After pre-treatment and micro-etching, the plate is released, such as figure 2 shown.

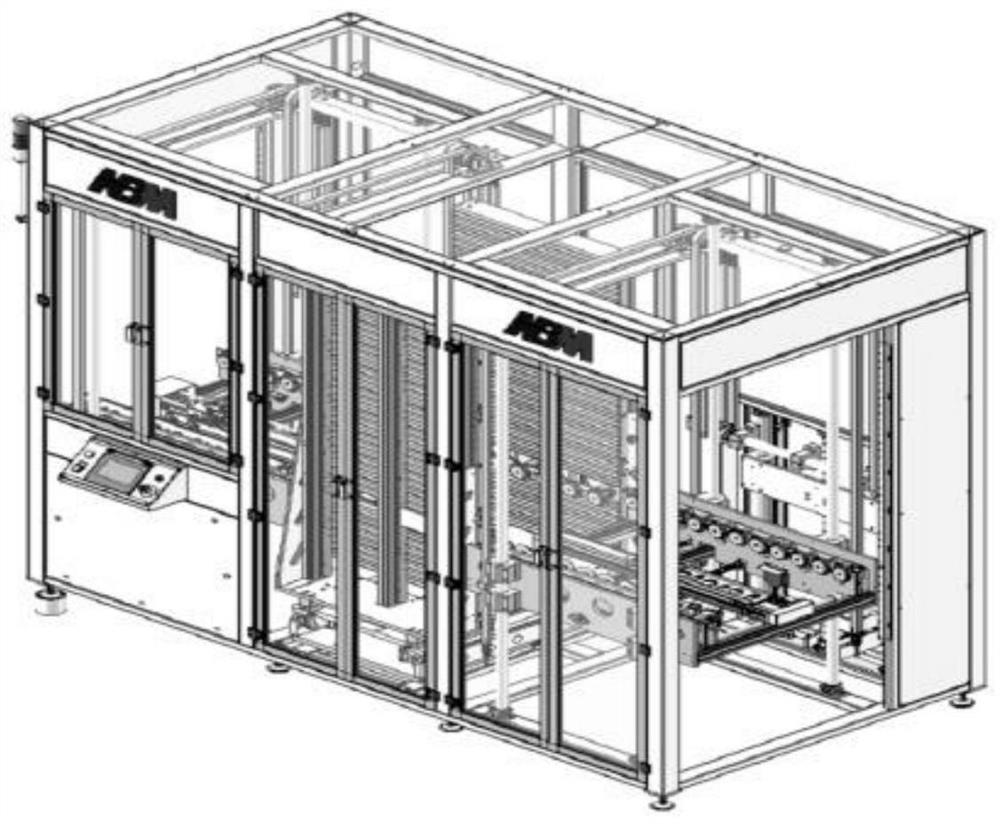

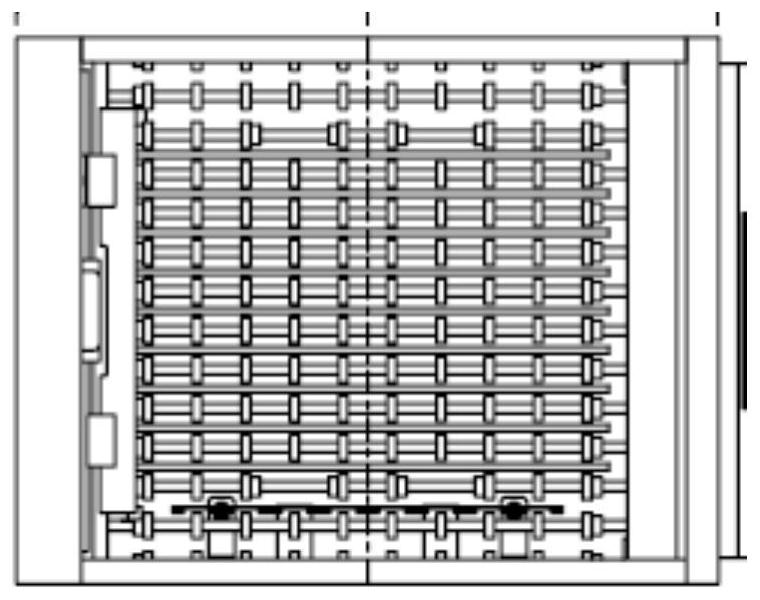

[0098] (2) Temporary storage machine (such as image 3 The prior art) carries out the temporary storage of the PCB board, and cooperates with the production capacity before and after.

[0099] (3) Film laminating speed improvement: (3.1) Optimize the film laminating machine's board-in + clap action, changing the deceleration / stop / clap / transportation of the board-in mechanism to deceleration / clap 3 times, and the running time is reduced from 1.5 seconds to 0.56 seconds. (3.2) Reduce the time of film application, (three elements of film application, temperature, pressure, speed), pressure from 0.35kg / cm 2 Increased to 0.40kg / cm 2 , increasing the temperature from the traditional 110°C to 120°C (using Figure 4 The preheating machine of the automatic film laminating mac...

Embodiment 2

[0103] The present invention utilizes 100 pieces of towbar-type temporary storage machine, matched with front and rear production capacity, 5.03 pieces per minute, and can be temporarily stored for 20 minutes. The dry film requires at least 15 minutes of temporary storage for the film, which meets the technical requirements.

[0104] Film production is generally 4 blocks / minute, exposure is 4.5-5 blocks / minute, and the utilization rate of direct connection exposure capacity is only about 80%-90%, which is not conducive to maximizing equipment capacity.

[0105] The invention increases the pressure and temperature of the film, increases the speed of the film, and increases the speed of the film to 5 pieces per minute, maximizing the matching production capacity.

[0106] Such as Figure 8 As mentioned above, it is the rendering of temporary storage, film application, temporary storage, and exposure production site. The overall length is about 23 meters.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com